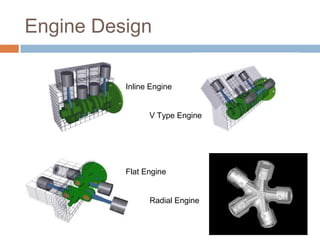

This document summarizes advances in internal combustion engines. It discusses major areas of advancement including engine design, material selection, timing controls, and fuel injection and combustion. It provides examples of various engine designs, materials used, and technologies like variable valve timing, cylinder deactivation, direct injection, supercharging, and turbocharging. It also briefly discusses six-stroke engine designs that aim to improve power and efficiency over traditional four-stroke engines.

![Classification of IC engines

Two main classifications:

Based on combustion

Spark Ignition [SI engines] (Eg: Petrol Engine)

Compression Ignition [CI engines] (Eg: Diesel

Engine)

Based on Number of strokes

Two stroke

Four Stroke

Six Stroke](https://image.slidesharecdn.com/advancesinicengines-120325133435-phpapp02-140330064118-phpapp02/85/Advancesinicengines-120325133435-phpapp02-3-320.jpg)