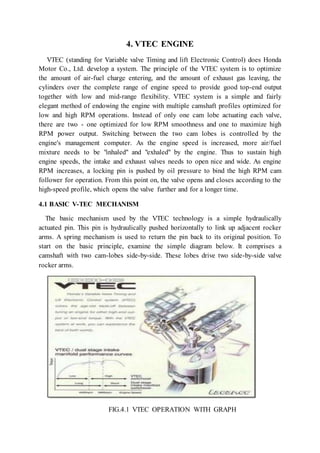

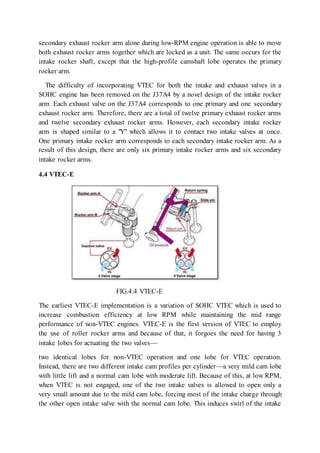

This document is a seminar report on intelligent variable valve timing and lift electronic control (i-VTEC) technology. It was submitted by a student to fulfill requirements for a bachelor's degree in mechanical engineering. The report provides background on i-VTEC, including its objectives, related terms, different VTEC systems, valve timing control, how the i-VTEC system works, advantages, disadvantages, and applications. It aims to explain this advanced internal combustion engine technology used in Honda vehicles.