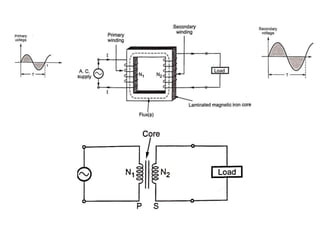

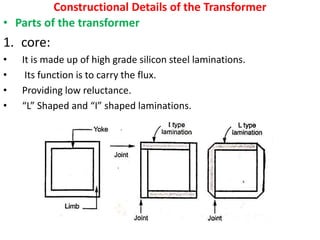

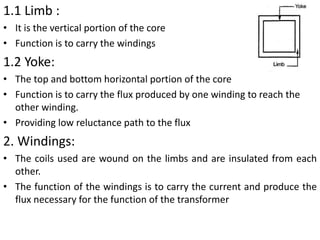

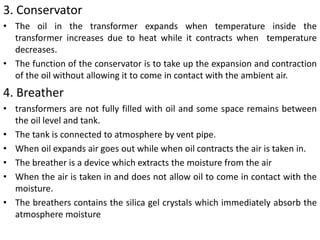

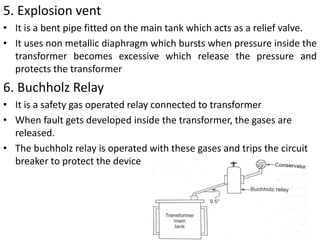

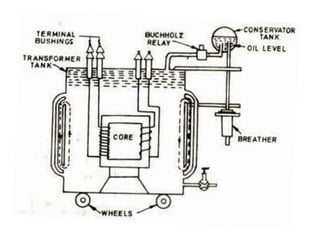

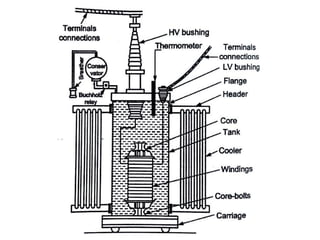

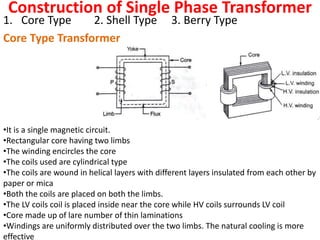

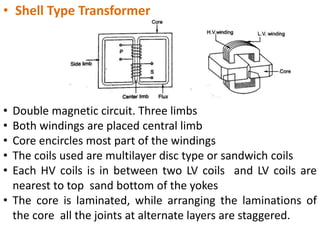

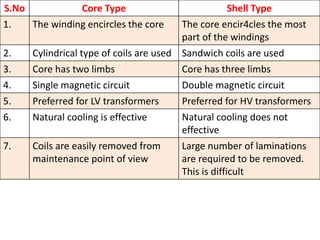

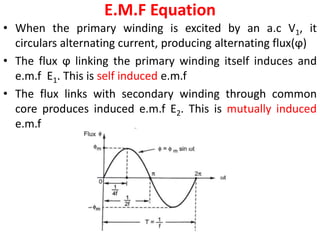

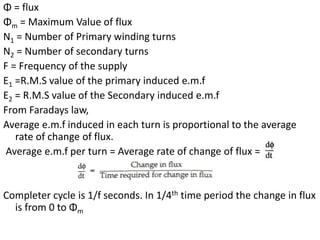

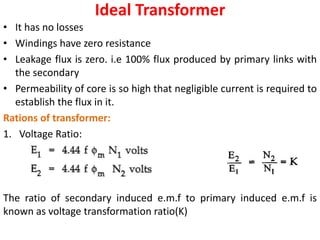

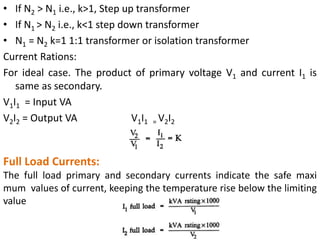

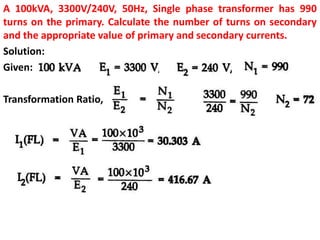

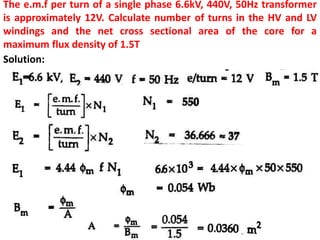

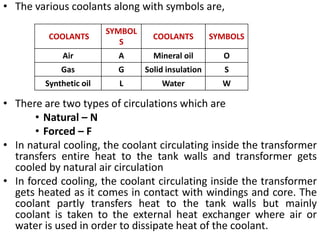

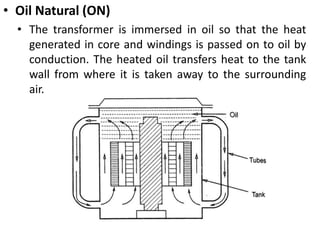

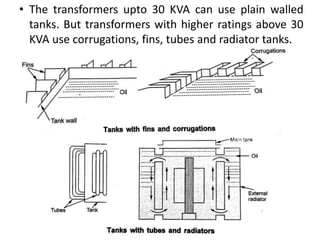

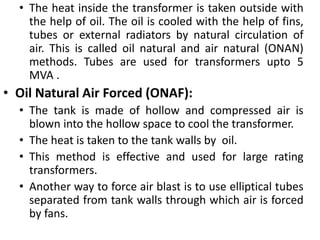

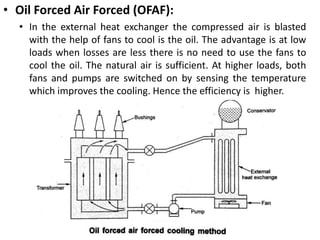

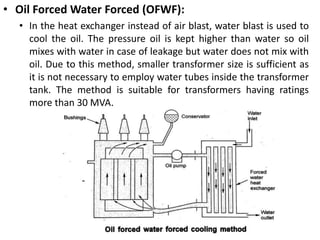

The transformer is a device that transfers electrical energy from one alternating current circuit to another through inductive coupling between coils. It increases or decreases voltage levels without changing frequency. The document describes the key components of a transformer including the core, windings, cooling methods, and equations for calculating voltages. It provides details on single phase transformer construction and cooling techniques like oil immersion.