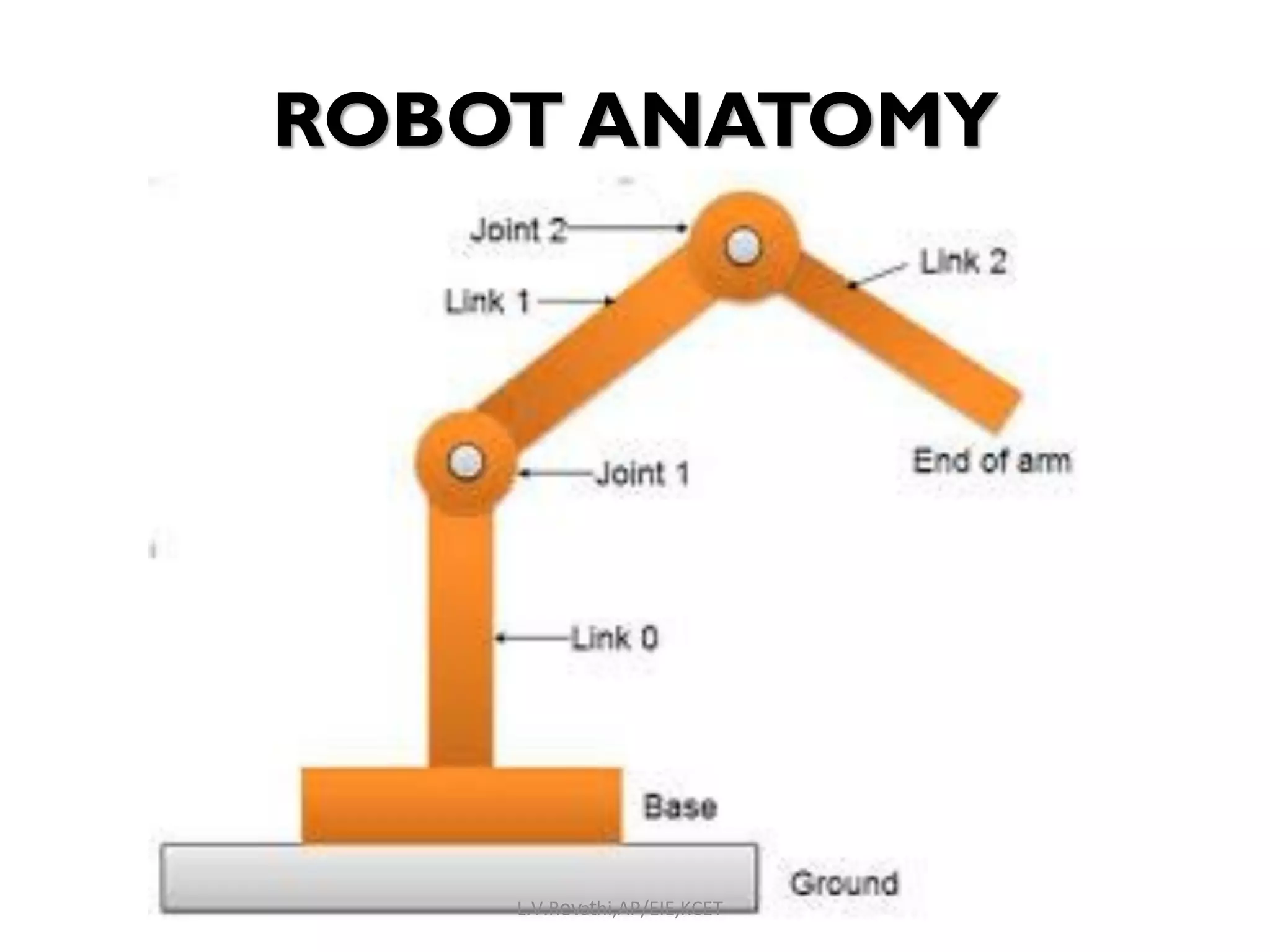

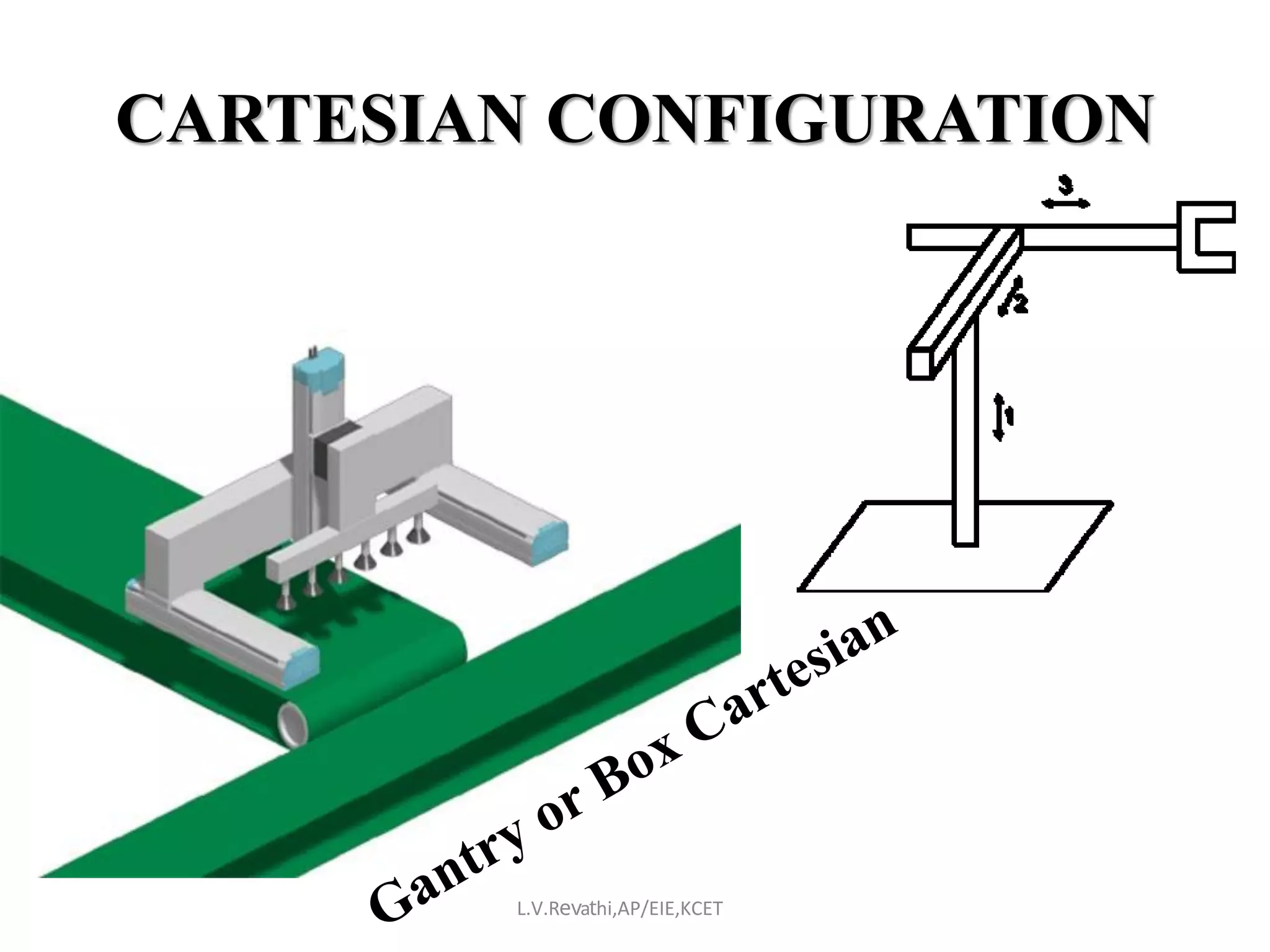

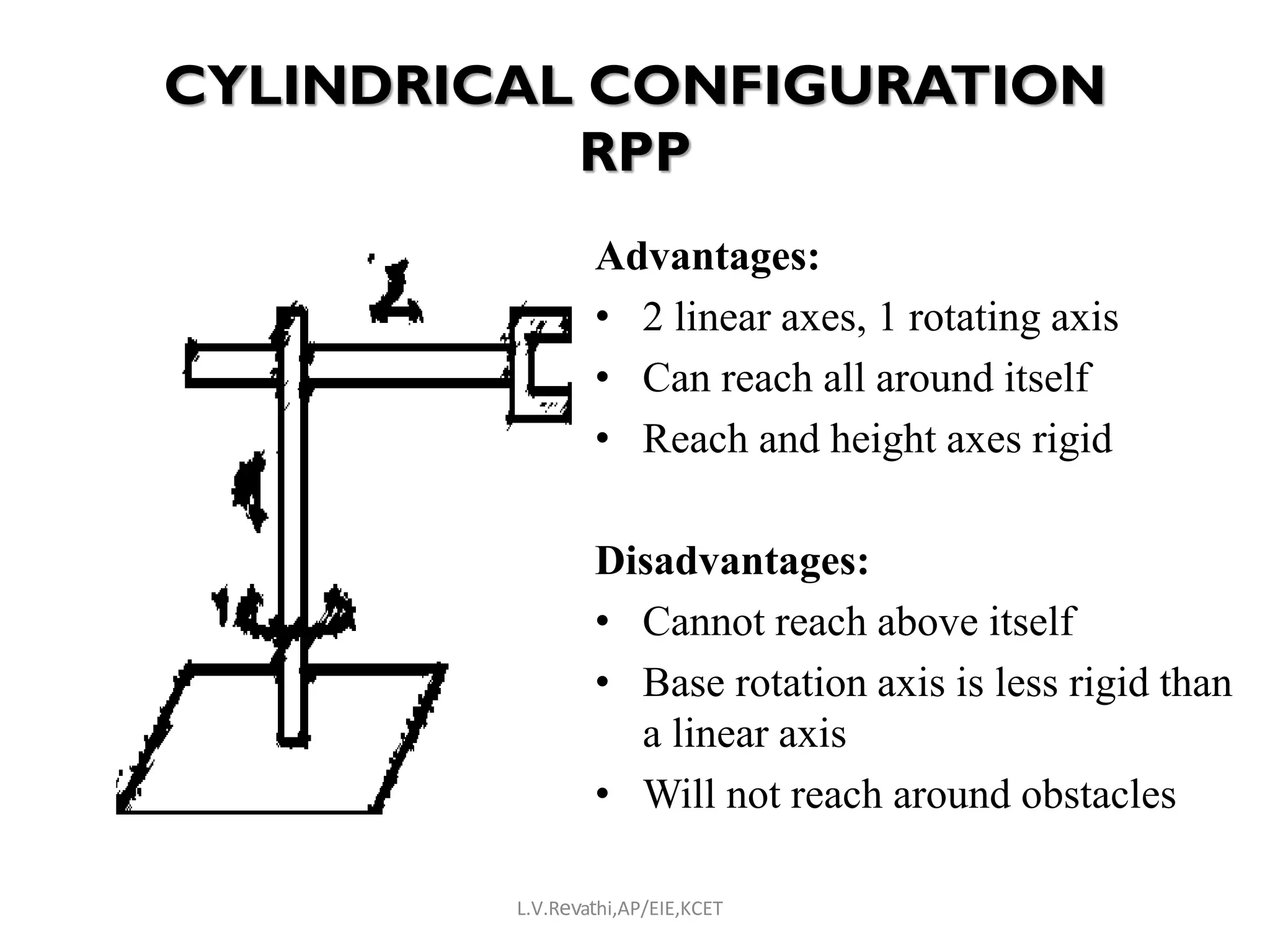

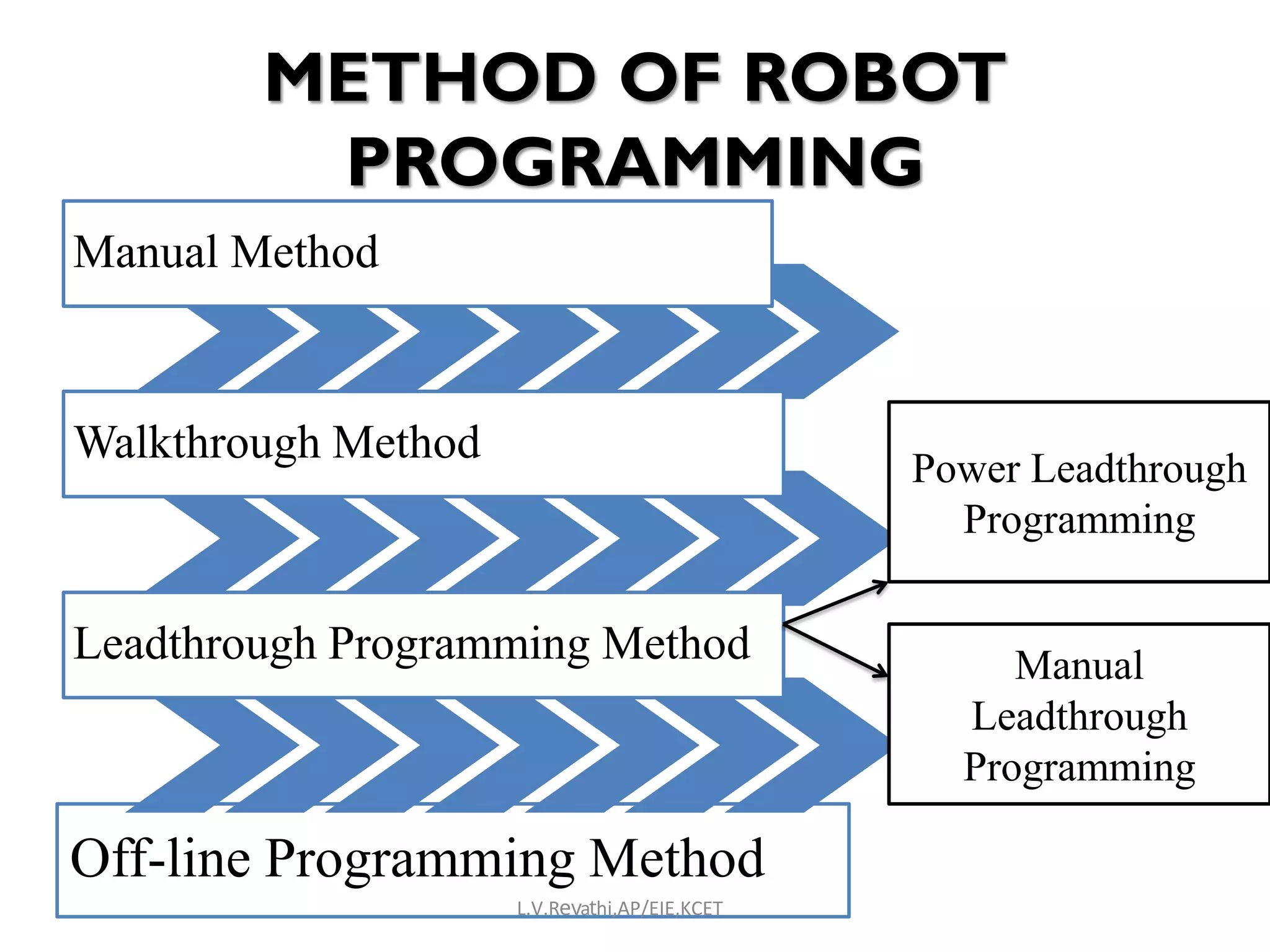

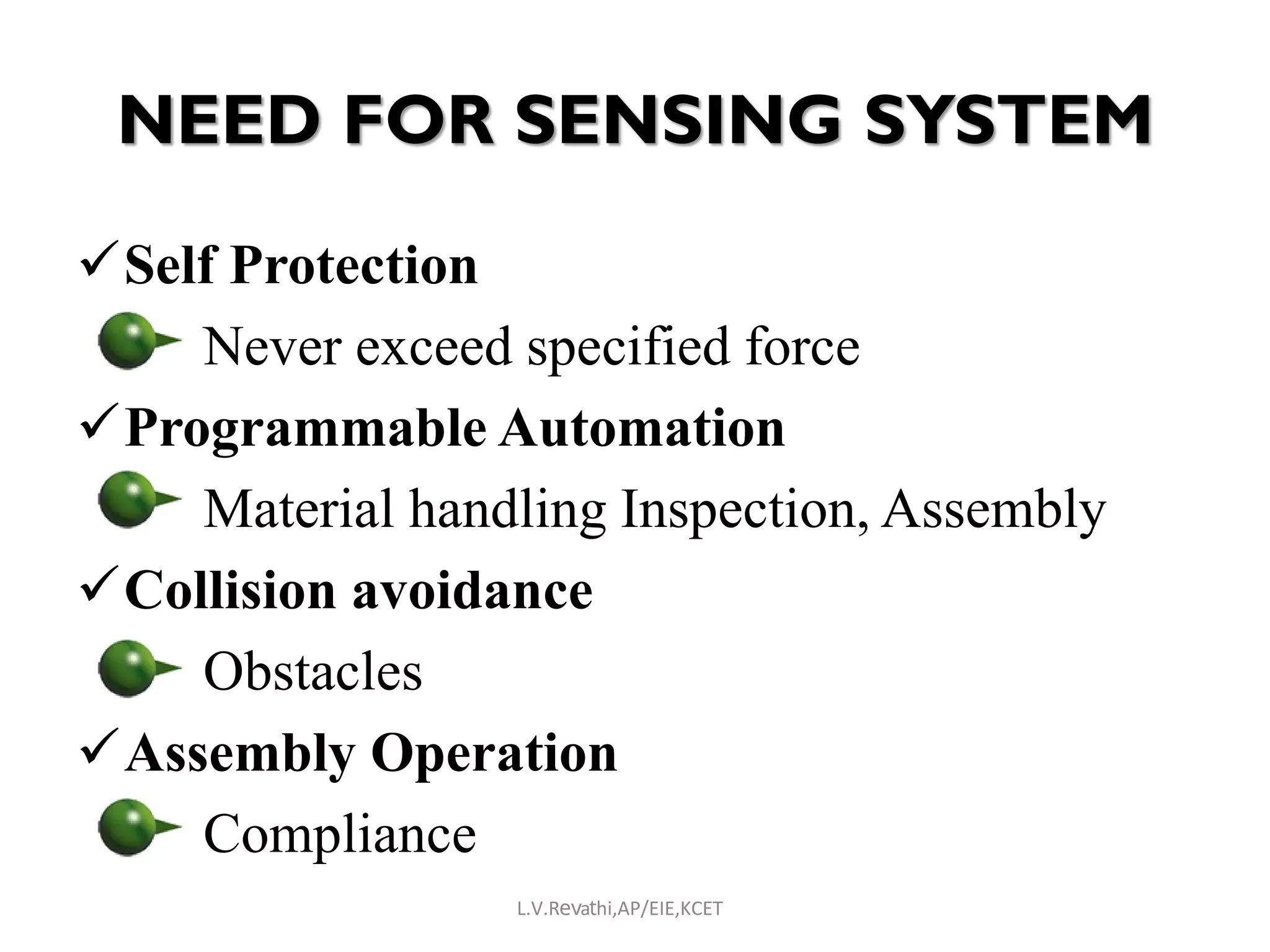

This document discusses the basics of robotics including different types, classifications, configurations, drives, programming, and sensing systems of robots. It covers 5 units: basic concepts, kinematics, manipulator motion and statics, path planning, and dynamics and control. Under basic concepts, it defines robots, discusses history, types including industrial, mobile, autonomous, and remote controlled robots. It also covers robot classifications based on physical configuration, control system, movement etc. and specifications.