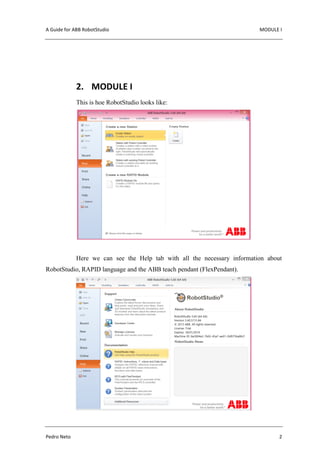

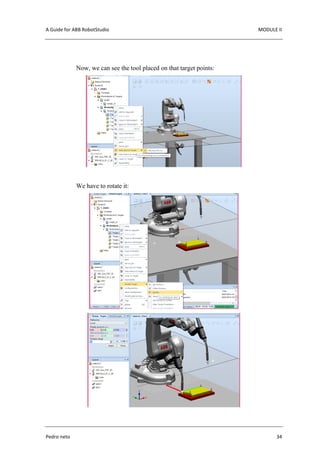

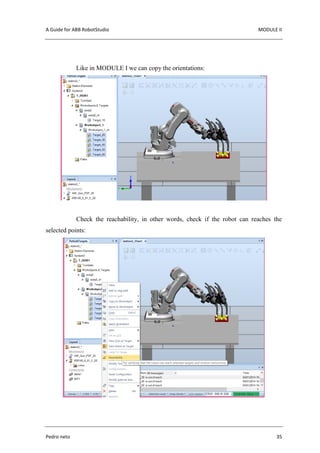

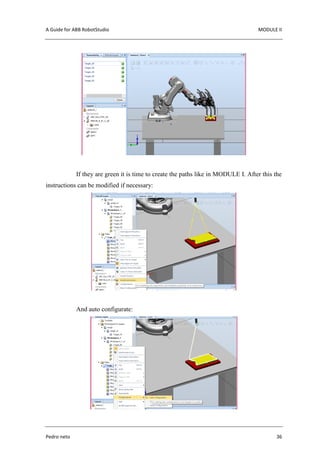

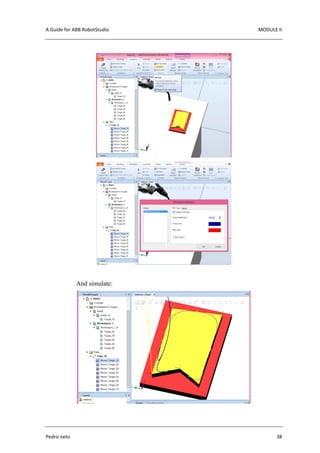

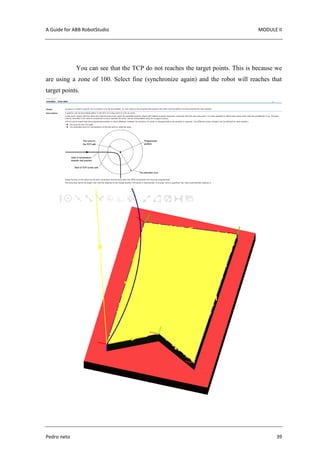

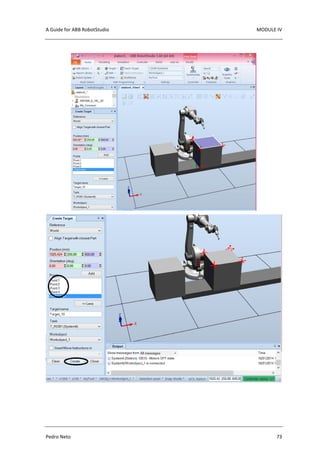

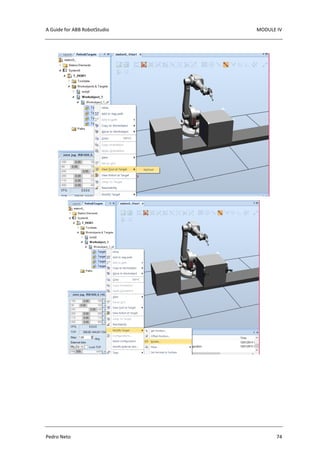

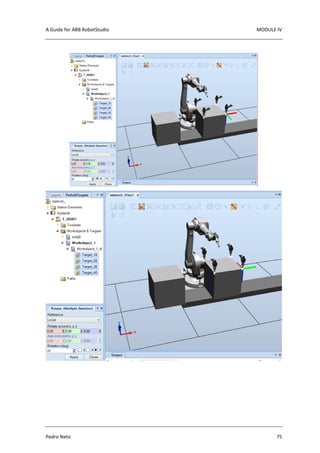

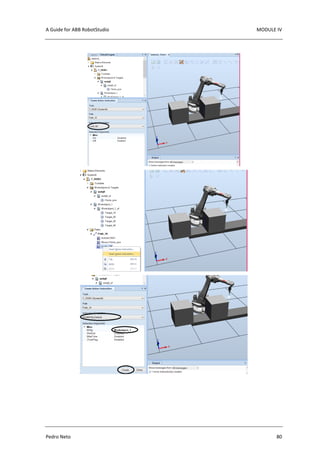

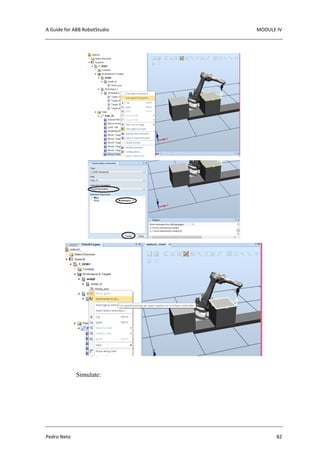

This document provides a guide for using ABB RobotStudio software. It is divided into modules that explain how to: 1) add robotic arms and position them correctly, 2) create workobjects and targets to define positions, 3) connect targets to create motion paths for simulation, and 4) use the virtual teach pendant to manually move the robot and create programs. The guide demonstrates basic functions for setting up and programming a robotic workcell in RobotStudio's offline programming environment.

![A Guide for ABB RobotStudio INTRODUCTION

[Nome do Aluno] 1

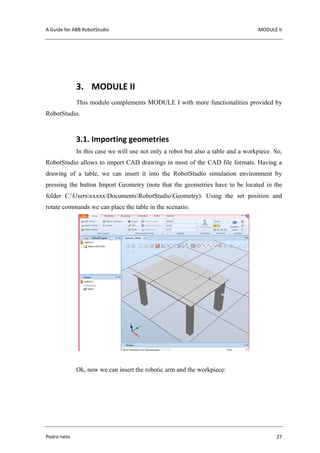

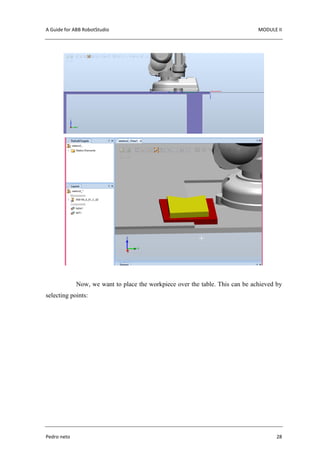

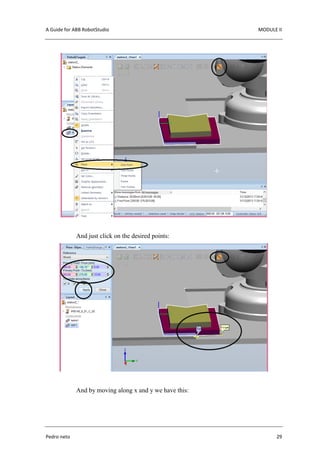

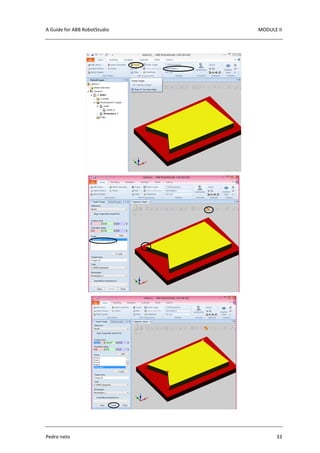

1. INTRODUCTION

This guide contains the basic commands to start using ABB RobotStudio. It is

divided in 4 modules in which each module is a different exercise. All the necessary

procedures to create a given robot application are described, step-by-step. Several print

screens from RobotStudio help to understand in a better way the process to operate

RobotStudio and create robot programs off-line.](https://image.slidesharecdn.com/robotstudioabb-160913222153/85/Robot-studio-abb-3-320.jpg)