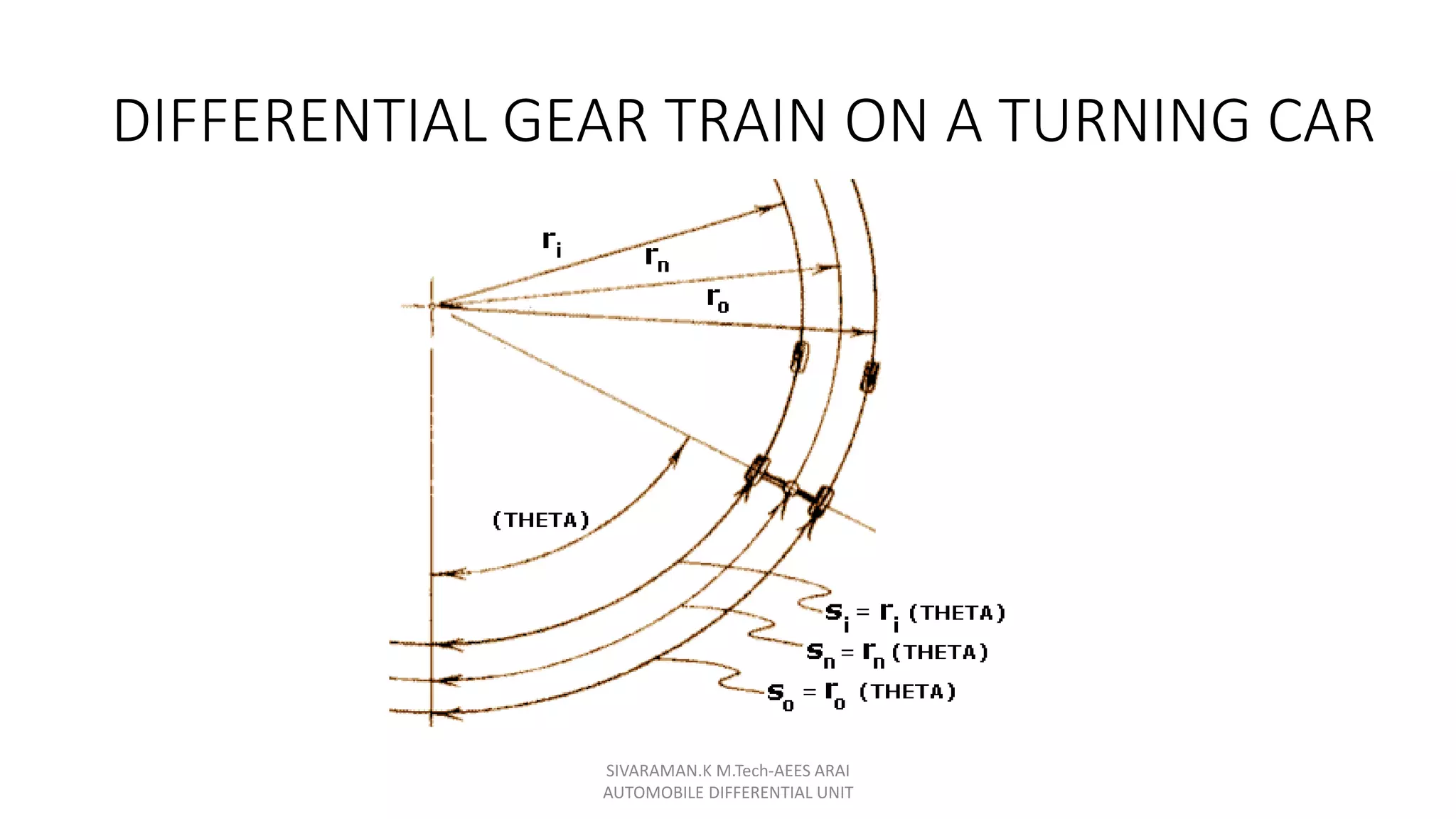

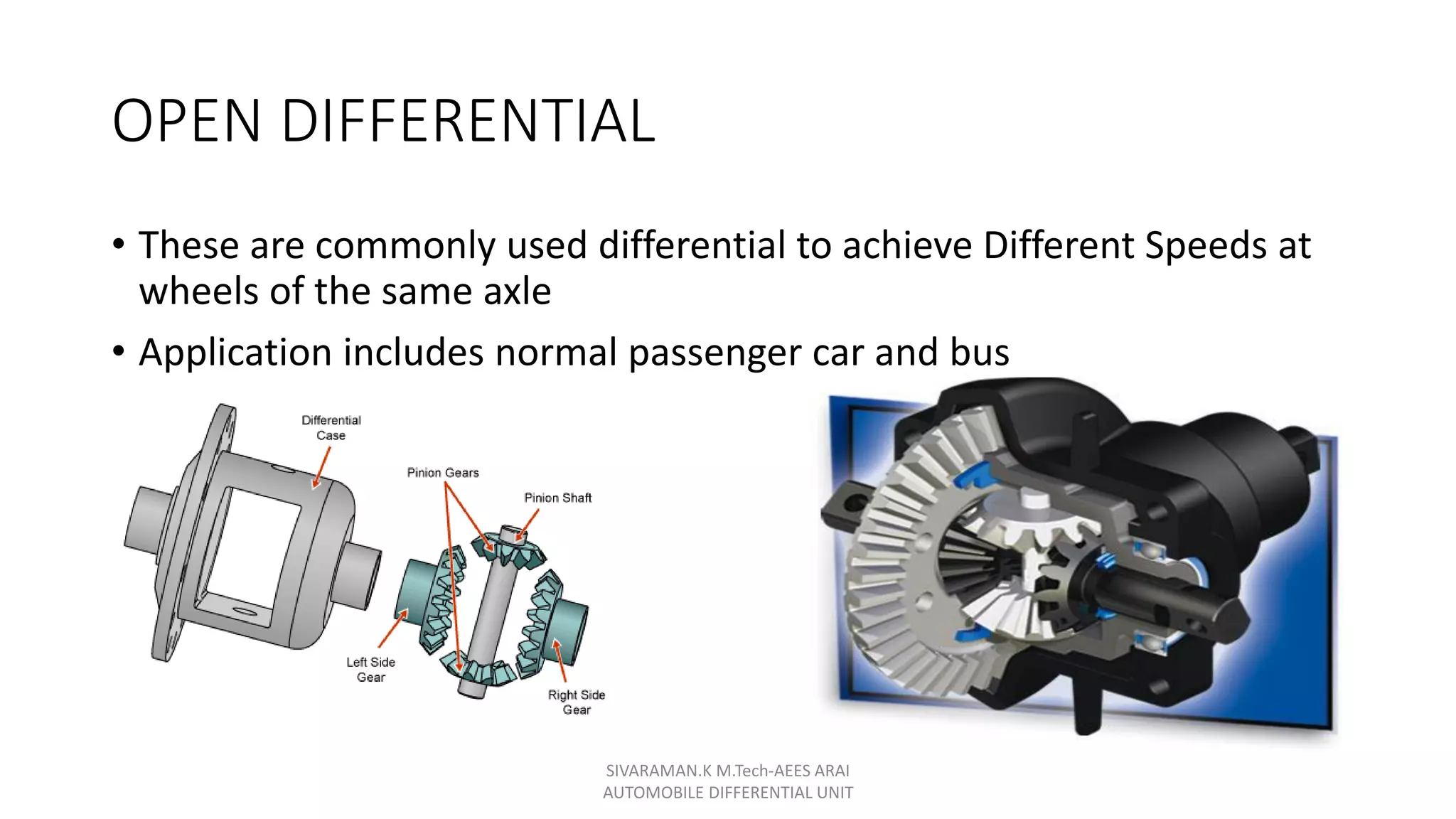

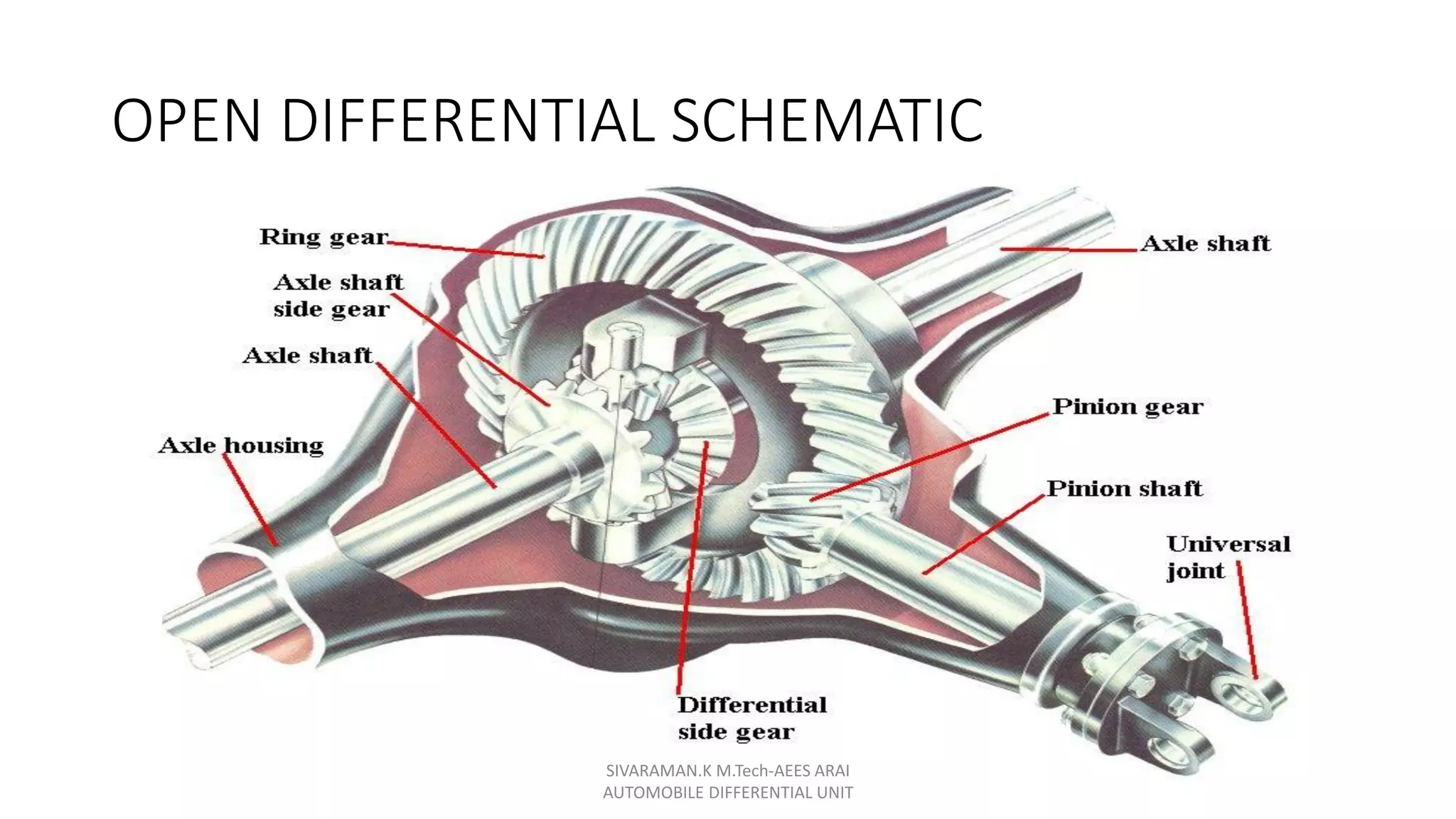

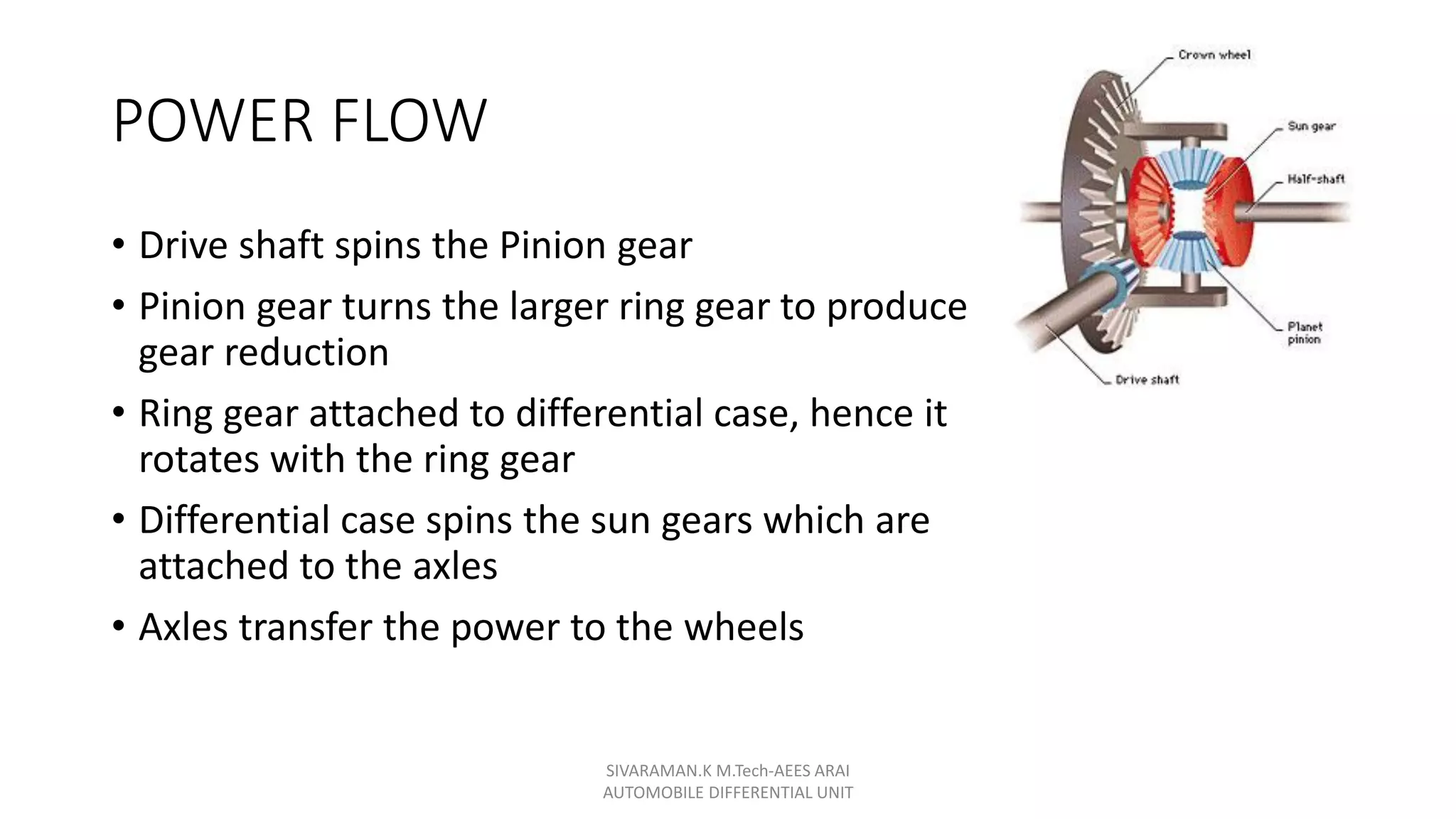

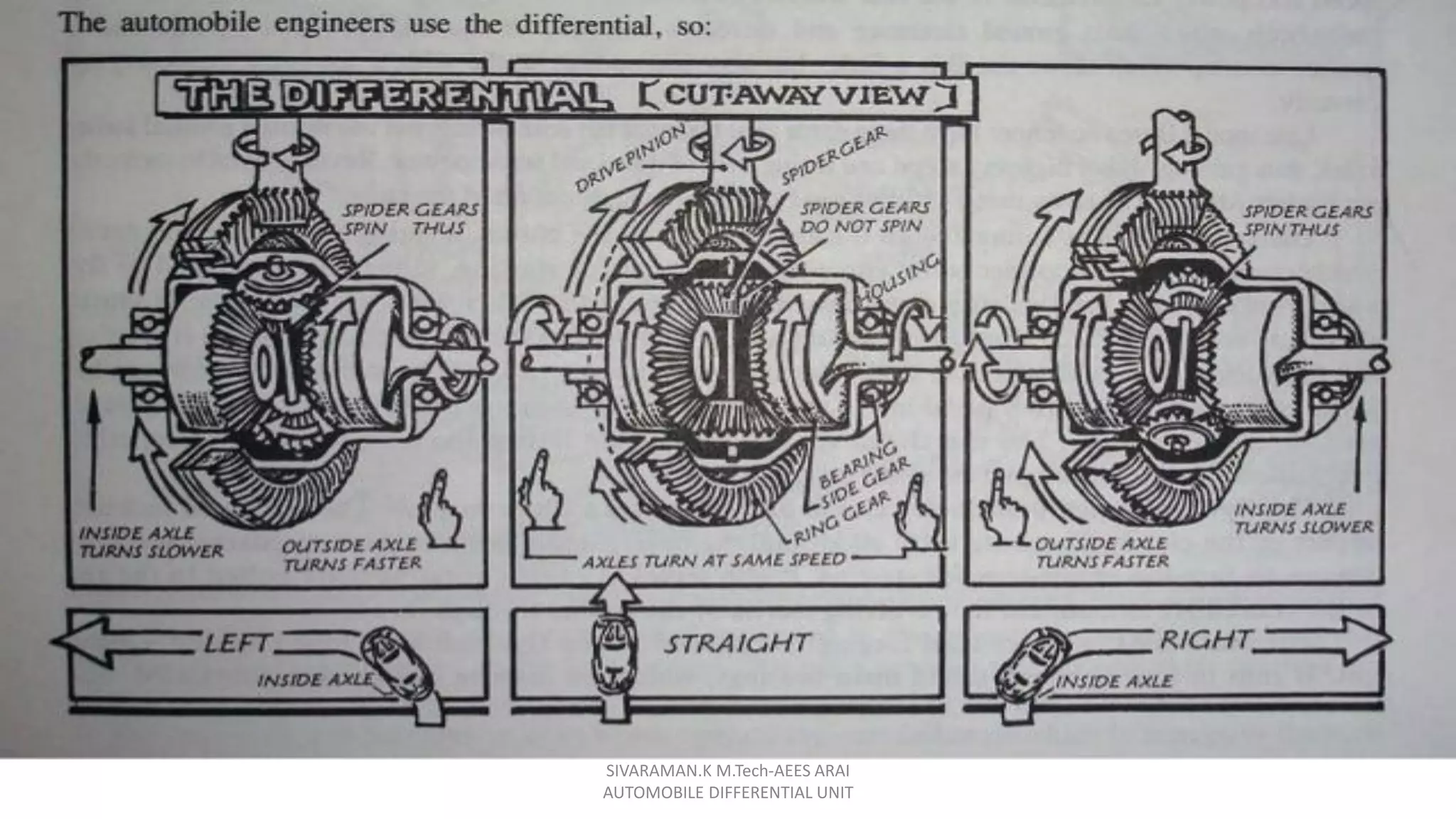

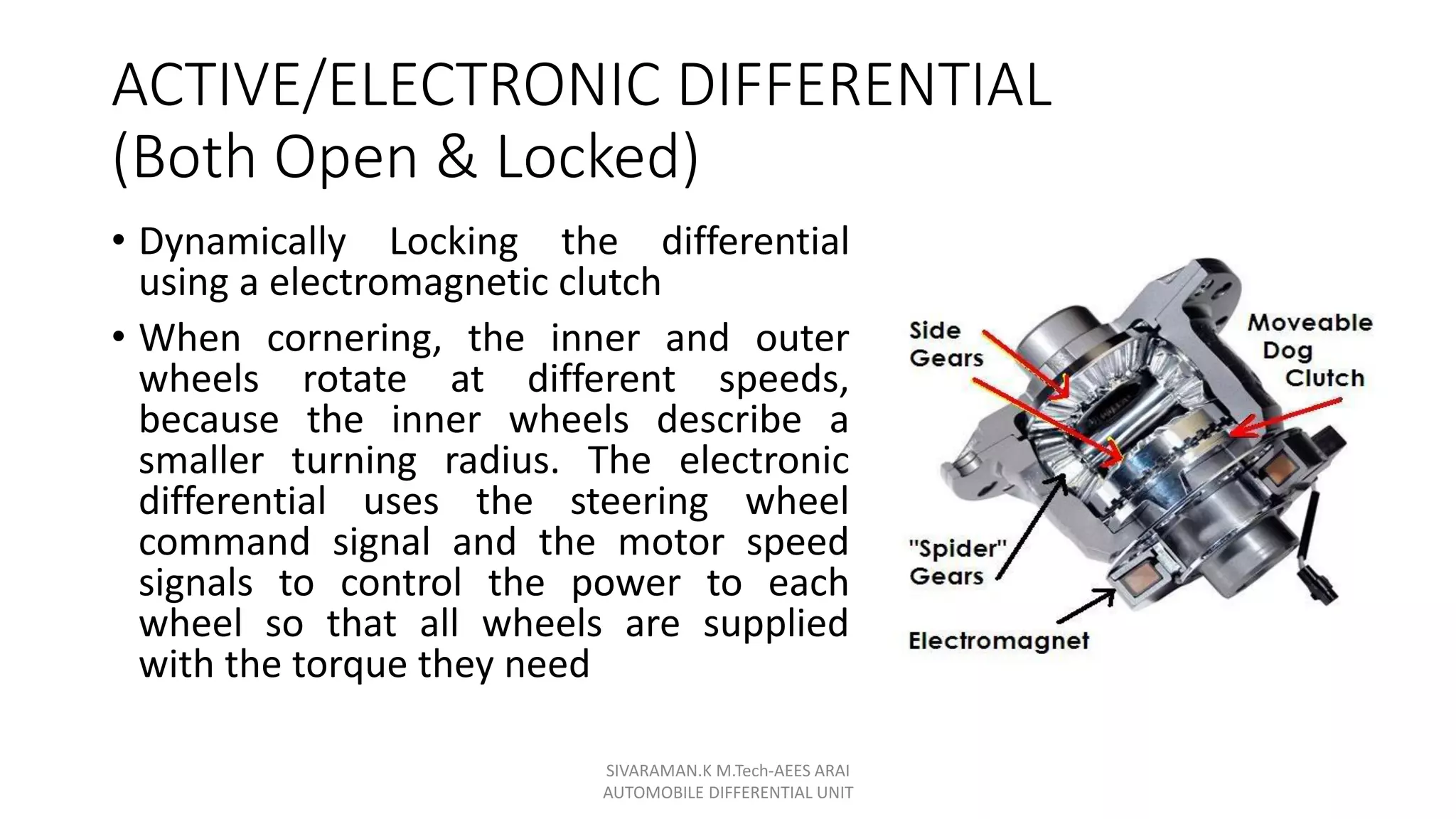

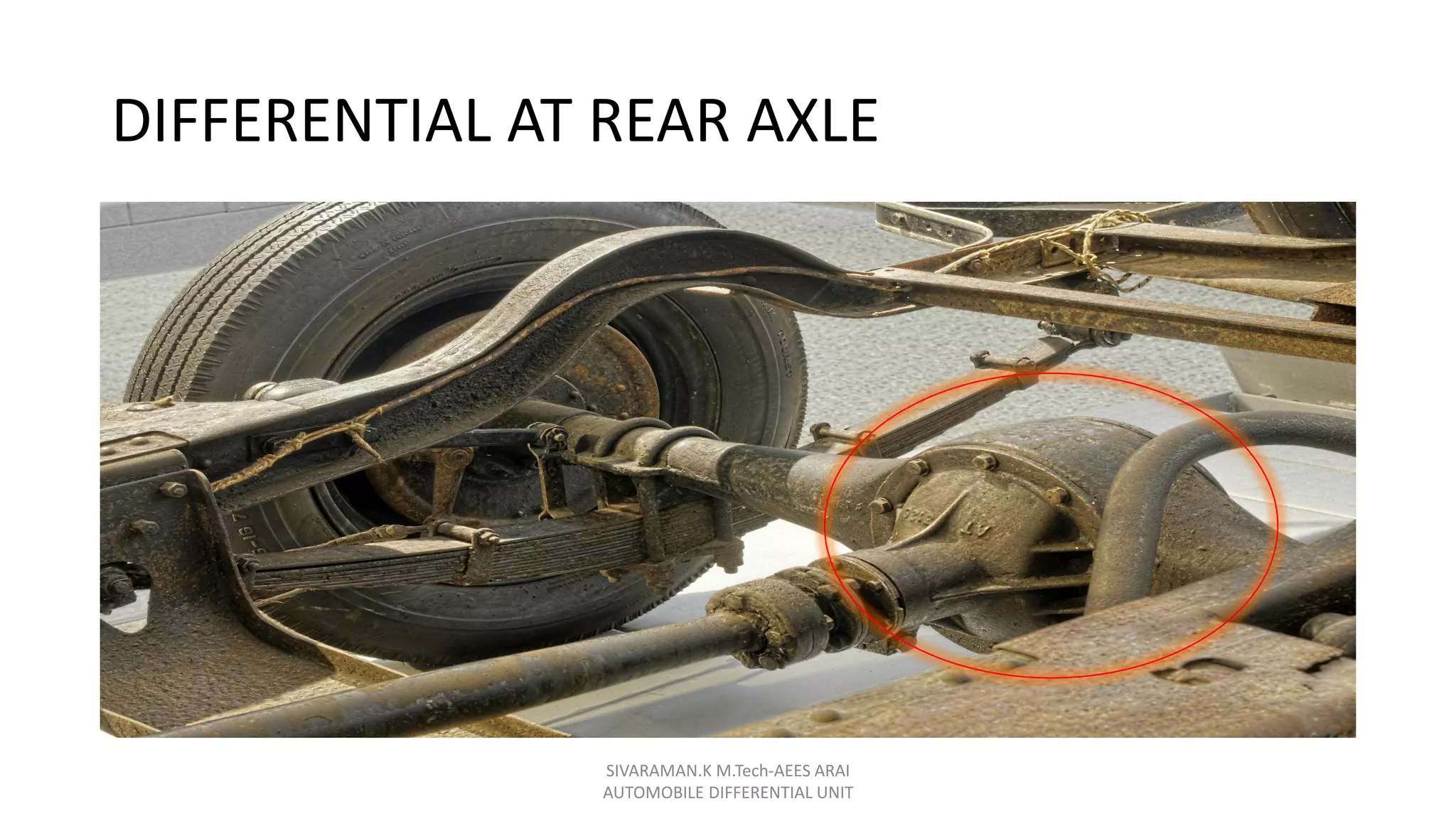

The document provides an overview of the automobile differential unit, detailing its functions, historical development, types, and components such as open, locked, active/electronic, and limited slip differentials. It outlines the mechanics of how these differentials enable distinct wheel speeds and torque distribution, particularly during turning and traction scenarios. Additionally, the document discusses maintenance procedures and common problems associated with differentials.

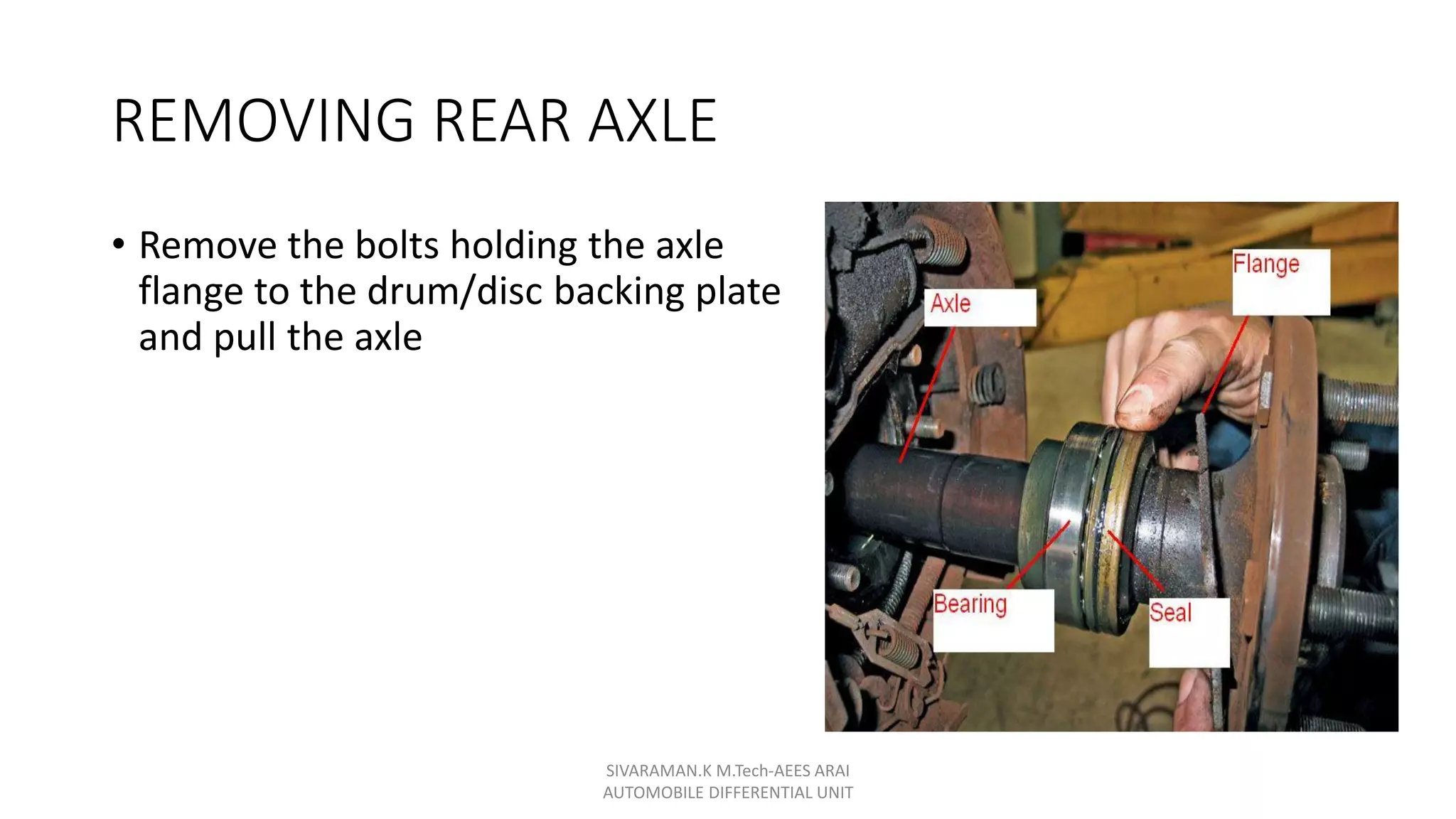

![HISTORY(BC)

• 227–239 AD: Ma Jun from the Kingdom of Wei in China invents the first historically

verifiable south-pointing chariot, which provided cardinal direction as a non-magnetic,

mechanized compass. Some such chariots may have used differential gears

• 658, 666 AD: 2 Chinese Buddhist monks and engineers create south-pointing chariots for

Emperor Tenji of Japan

• 1720: Joseph Williamson uses a differential gear in a clock.

• 1810: Rudolph Ackermann of Germany invents a four-wheel steering system for carriages

• 1827: modern automotive differential patented by watchmaker Onésiphore Pecqueur

(1792–1852) of the Conservatoire des Arts et Métiers in France for use on a steam cart.

(Sources: Britannica Online and[3])

SIVARAMAN.K M.Tech-AEES ARAI

AUTOMOBILE DIFFERENTIAL UNIT

• Antikythera Mechanism

HISTORY(AD)](https://image.slidesharecdn.com/differentialassignment-150910220028-lva1-app6891/75/Automobile-Differential-Unit-4-2048.jpg)