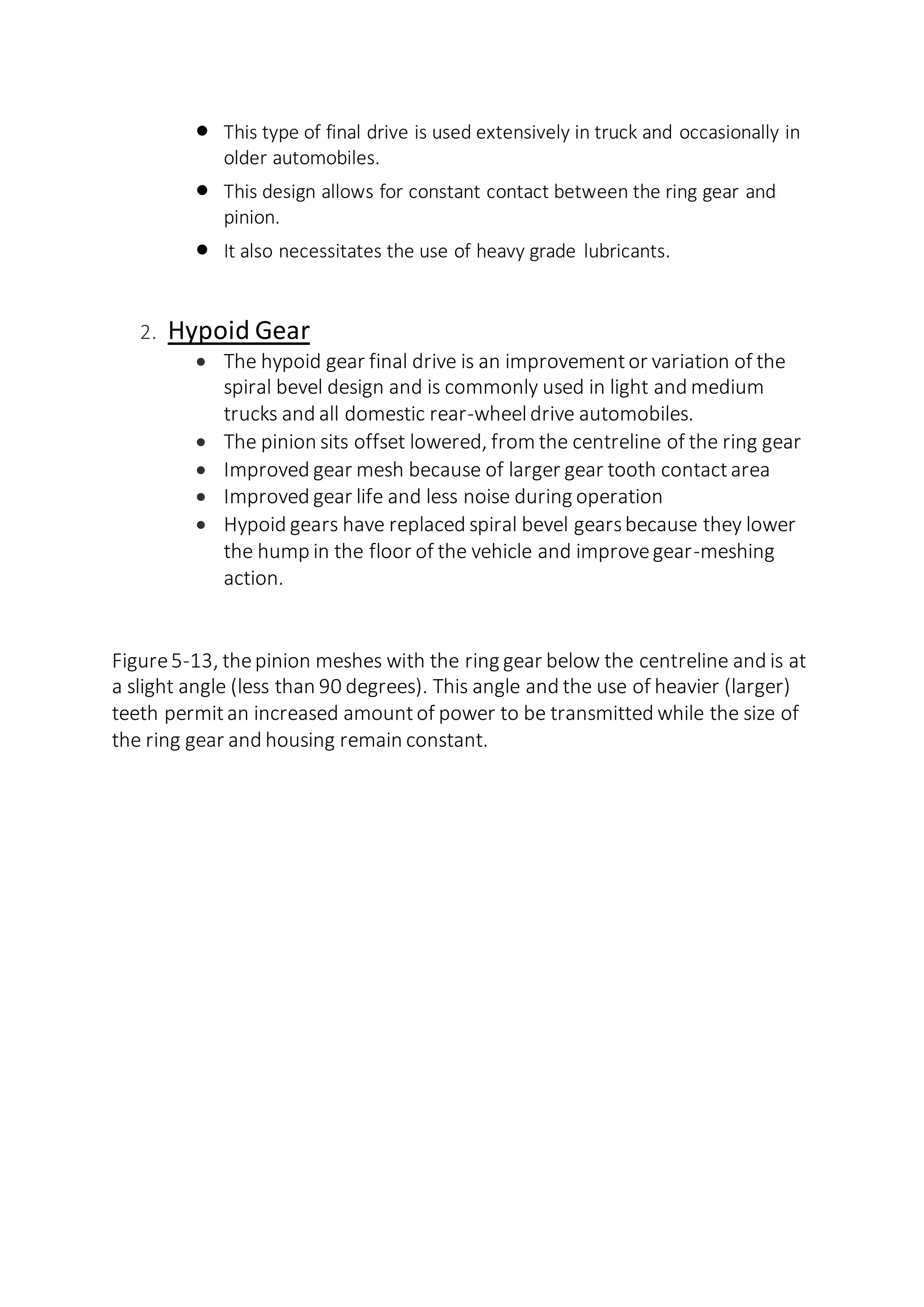

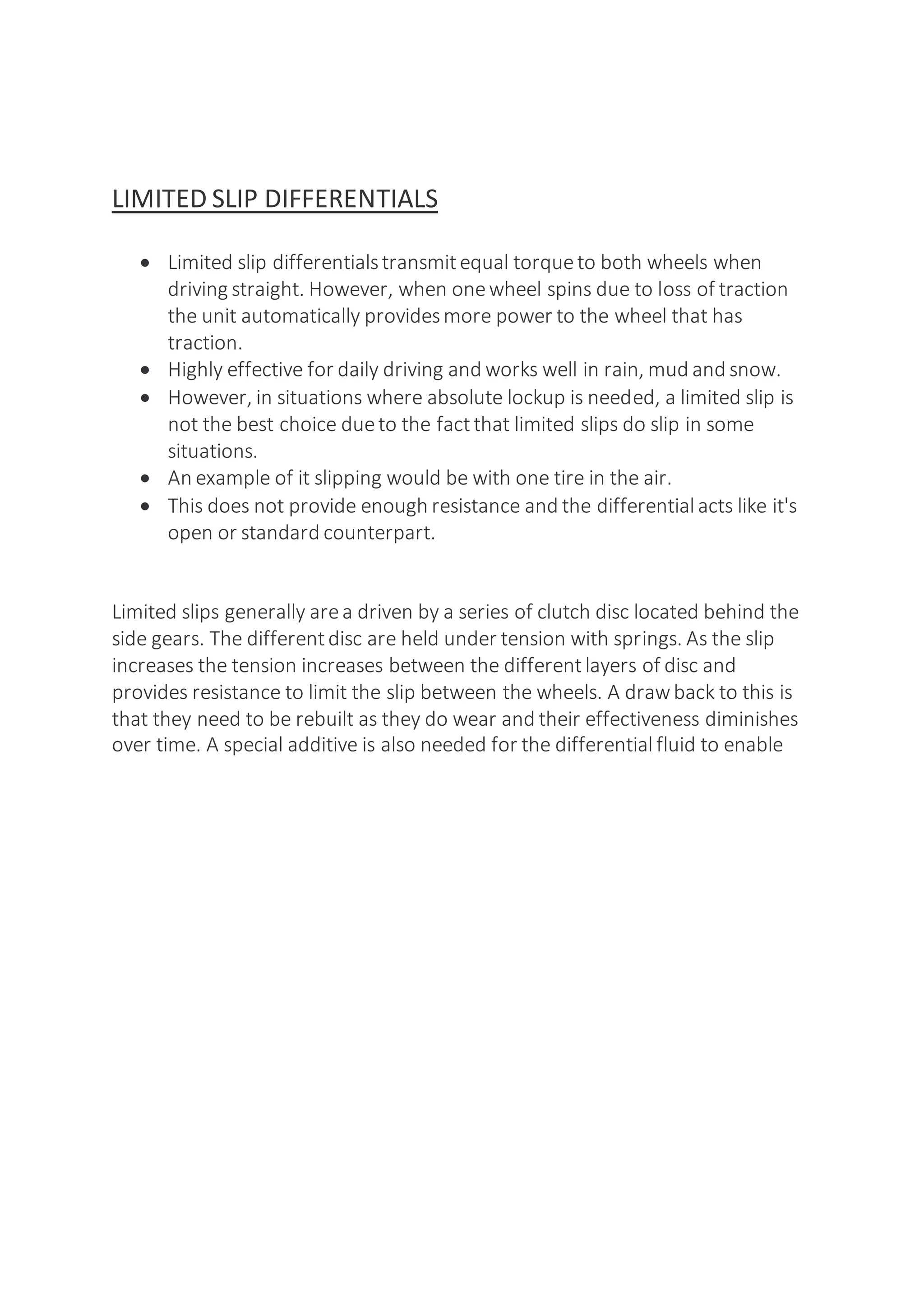

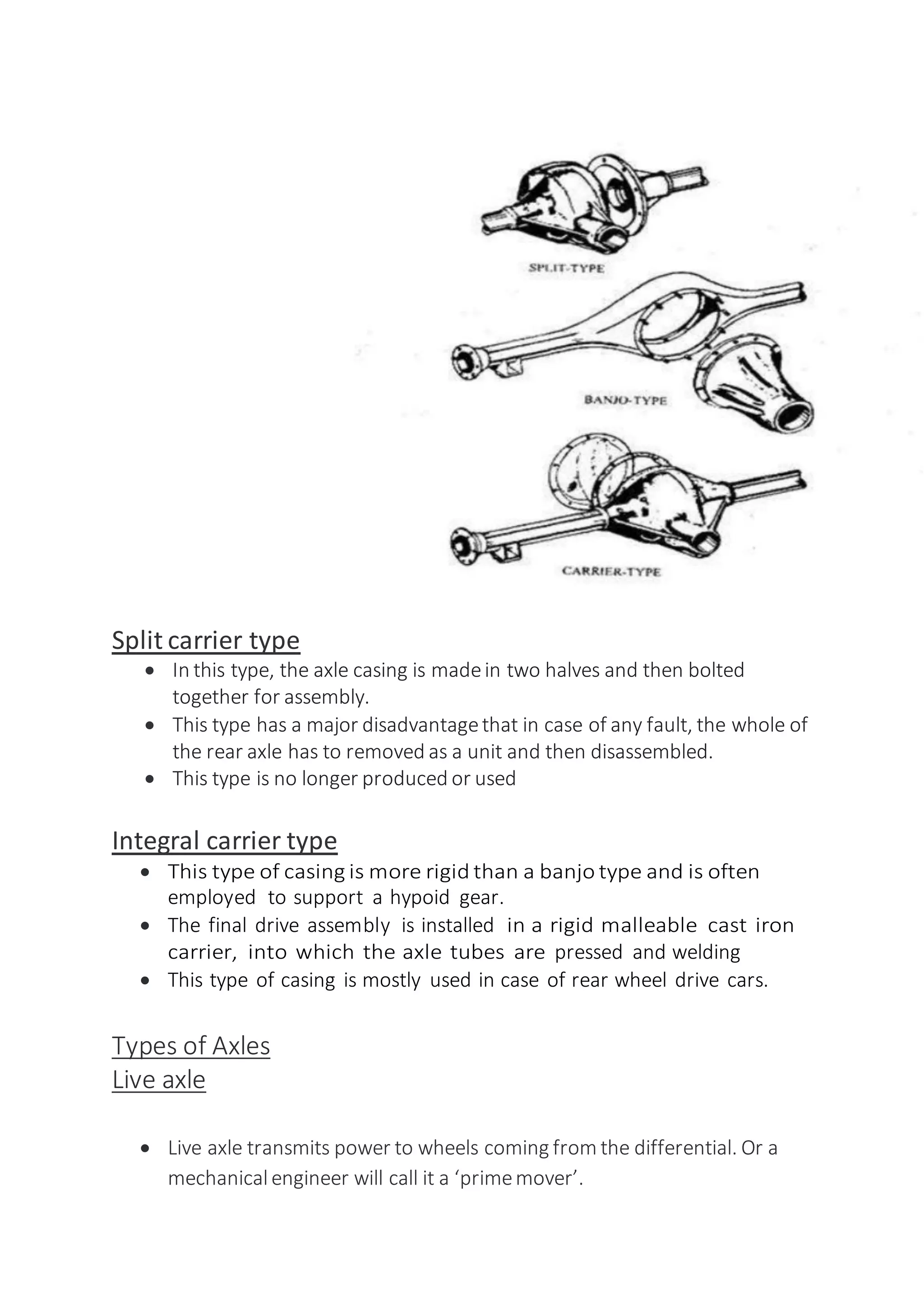

The document discusses differentials and their components. A differential is located in the rear axle assembly and splits torque from the drive shaft to allow the left and right wheels to spin at different speeds when turning. It discusses the types of gears used including spiral bevel gears and hypoid gears. It also describes the different types of differentials including open differentials, limited slip differentials, and locking differentials. The advantages and disadvantages of each type are provided. Measurements and adjustments that are important for differentials like pinion gear depth, pinion bearing preload, and ring and pinion backlash are also outlined.