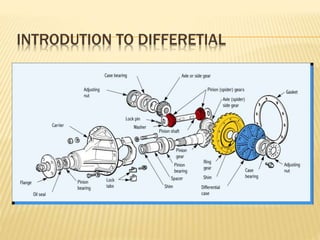

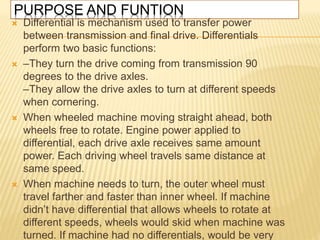

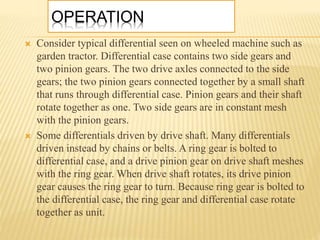

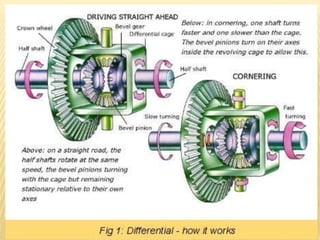

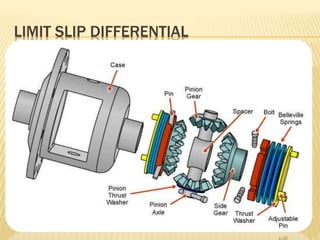

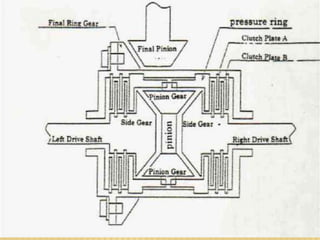

- The drive pinion drives the ring gear which is attached to the differential case. When going straight ahead, power is transferred equally to both wheels. When turning a corner, the wheels must travel at different speeds to prevent tire scrubbing, so the differential pinion gears "walk" around the slower side gear to cause the other side gear to turn faster.

- Limited-slip differentials limit the amount of differential action allowed compared to open differentials. They provide more driving force to the wheel with traction when one wheel begins to slip while still allowing wheels to turn at different speeds when cornering.

- In operation, driving torque is transmitted equally to each axle until traction is lost by one wheel. Then