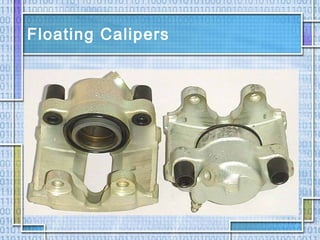

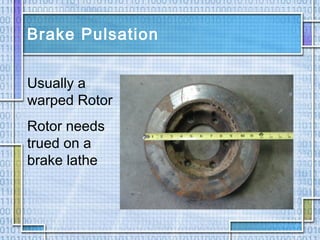

This document discusses the main components of automotive disc brakes, including the mounting bracket, rotor, caliper, and pads. It describes the purpose and basic operation of each part. The rotor comes in vented and non-vented varieties and can require repair work like truing. Calipers are either fixed or floating and contain pistons and seals. Disc brakes are self-adjusting, and wear indicators help detect when pads need replacement. Common brake issues like noise, pulsation, and excessive pedal travel are also briefly mentioned.