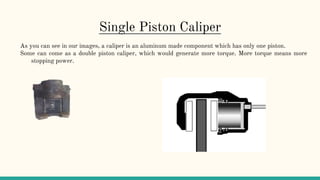

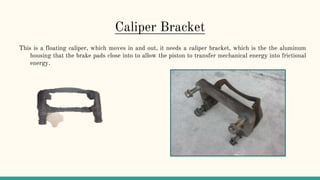

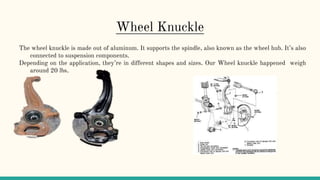

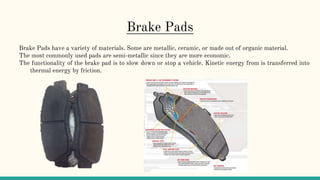

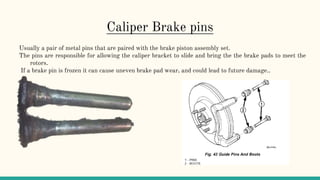

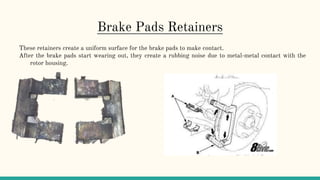

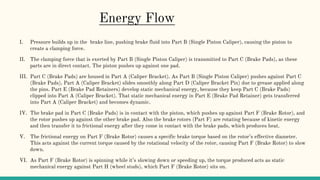

The document summarizes the components and operation of an automobile brake system. It describes the basic components including the caliper, caliper bracket, brake pads, rotors, and how hydraulic pressure is transferred through the system to create friction between the pads and rotors to slow the wheels. It then provides more detail on individual components like wheel knuckles, caliper pins, and pad retainers. It explains how kinetic energy from the moving rotor is transferred into thermal energy through friction to slow the car. In conclusion, it discusses the global, economic, and environmental impacts of brake system production and operation.