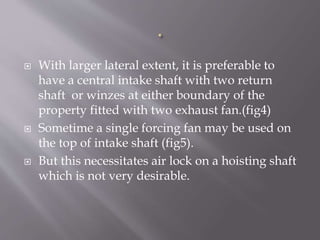

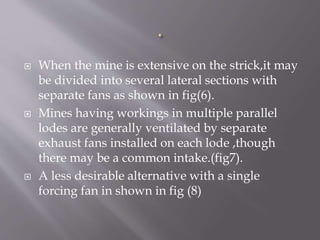

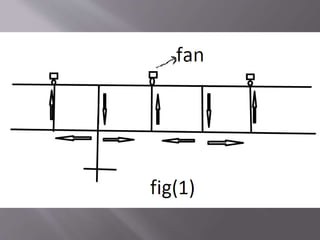

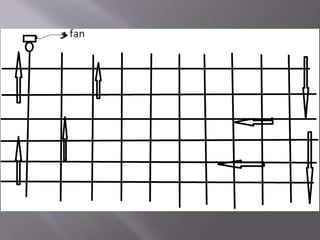

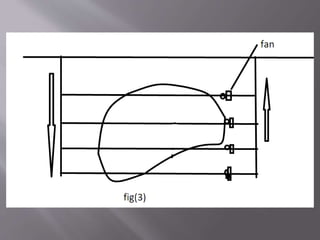

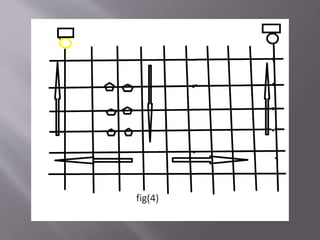

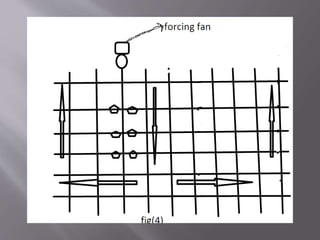

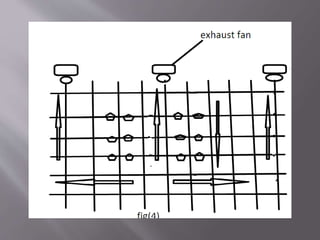

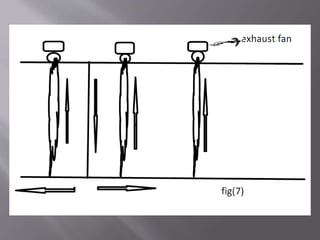

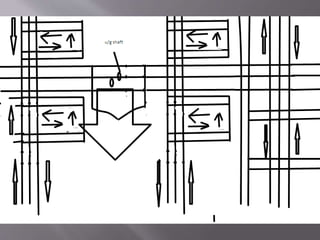

The document discusses different types of ventilation systems used in mines: boundary, central, and combined. The boundary system uses unidirectional airflow from intake to return shafts located at the mine boundaries, requiring minimal ventilation control. It is most efficient but limited by mine size. The central system uses bidirectional airflow in parallel roadways separated by stoppings, allowing ventilation of larger areas but with greater airflow leakage.