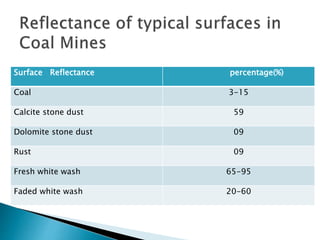

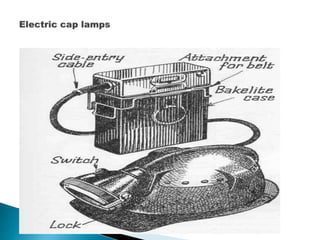

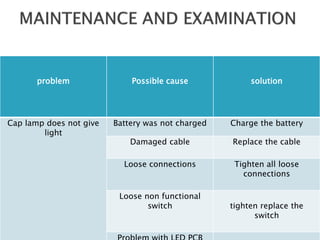

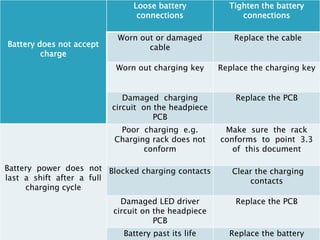

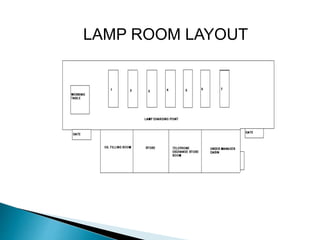

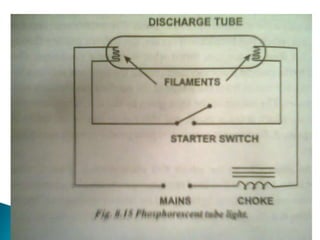

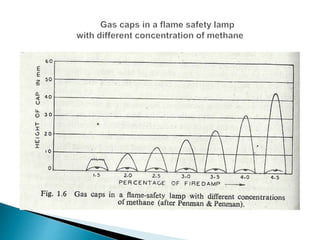

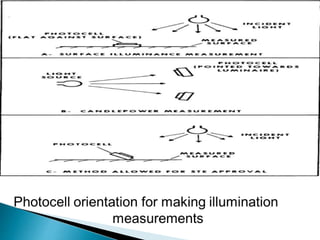

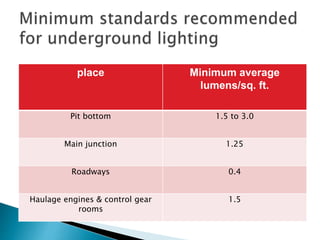

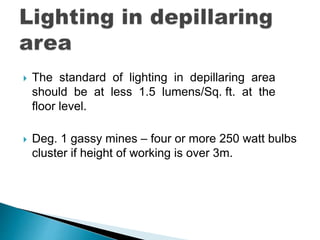

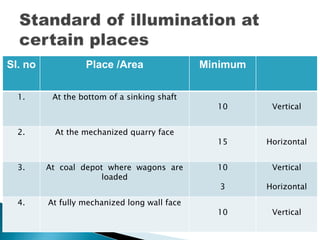

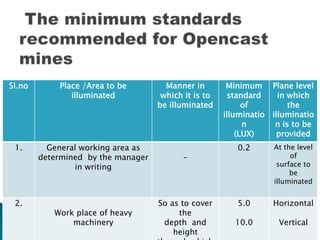

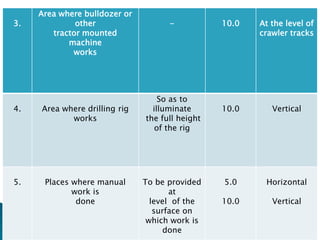

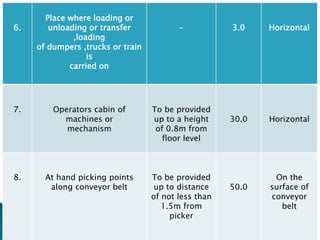

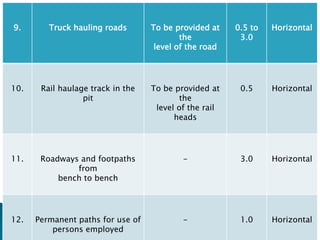

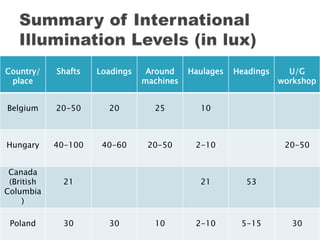

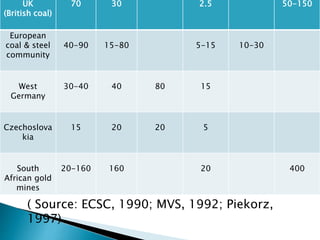

This document discusses lighting in mines and light physics concepts. It provides details on various types of lamps used in mines including acetylene lamps, flameproof safety torches, and electric cap lamps. It describes the layout of a lamp room and issues that may occur with cap lamps. Lighting arrangements and illumination levels for mines are also covered. Discharge lamps and fluorescent tubes for mine lighting are discussed. Testing for gas accumulation and percentage in mines using safety lamps is summarized.