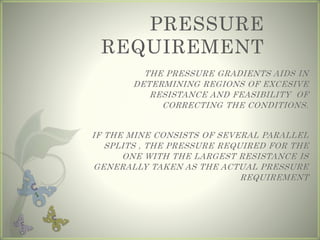

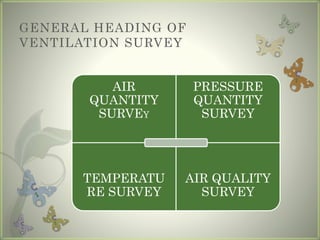

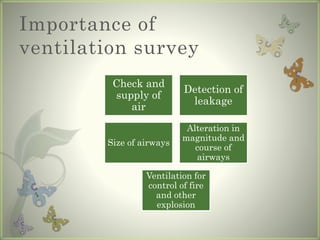

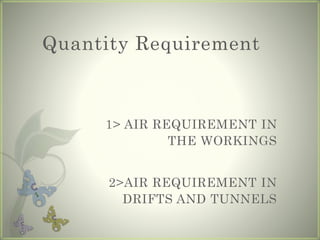

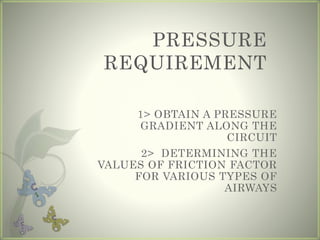

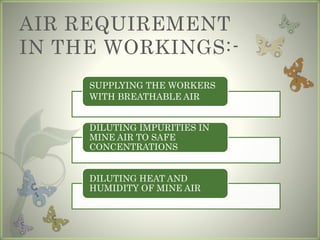

This document discusses the calculation of pressure and quantity measurement for ventilation surveys in mines. It covers determining air requirements for mine workings based on factors like diluting gases, heat, and providing breathable air for workers. Methods for calculating flow rates, pressure losses, and leakage are presented for proper ventilation system design. Key aspects addressed include determining pressure gradients, friction losses, emissions from coal faces and blasting, and total air quantity needs for the entire mine network.

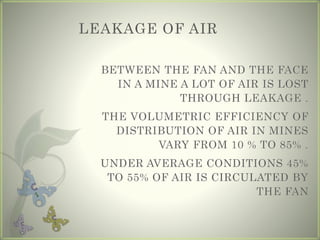

![IF THE MINE IS TO BE PLANNED FOR

DEPTHS FOR WHICH NO METHANE

EMISSION DATA CAN BE OBTAINED , IT

WOULD BE WISE TO ALLOW A 10 %

INCREASE IN THE RATE OF GAS EMISSION

FOR EVERY 100M DEPTH .

RADON DOUGHTERS [RADIOACTIVE

MINERALS ] :-- MAXIMUM PER LIMIT = 1/10

U Ci/m3

1 Ci = 37 BILLION DPS

1mCi = 37000DPS . MINIMUM 0.5 M3/S

SHOULD BE DELIVERED FROM A TUBE

OUTLET AT A INSTANCE NOT EXCEEDING

9M FROM FACE FOR EVERY PAIR OF MAN

MINING URANIUM CORE](https://image.slidesharecdn.com/pressurequantitymeasurement-161015103208/85/Pressure-quantity-measurement-10-320.jpg)

![TOTAL QUANTITY OF

MINE

Qsh = [ ∑ Qut.sch + 1.1 ( ∑ Qp + ∑Qo .v + ∑ Qk +

∑Qut) ] Kz-u

Qut.sch = AIR REQ TO VENTILATE IN A

DISTRICT

Qp = VENTILATON OF DEVELOPMENT FACE

Qov = VENTILATION OF ISOLATED WORKING

Qk = AIR FOR ROOMS OUTSIDE THE DISTRICT

Qut = LOSSES THROUGH VENTILATION

DEVICES](https://image.slidesharecdn.com/pressurequantitymeasurement-161015103208/85/Pressure-quantity-measurement-24-320.jpg)