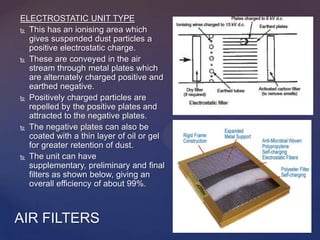

This document discusses ventilation requirements and systems. It defines ventilation as changing the air in an enclosed space to provide fresh air for respiration and control factors like carbon dioxide, moisture, heat, and odors. Ventilation requirements vary by building usage but are often measured in air changes per hour. Systems can be natural (using airflow without fans) or mechanical (using ducts and fans). Natural ventilation provides benefits like improved indoor air quality but requires proper building design. Mechanical systems provide more air flow control and constant fresh air intake. Common mechanical systems include natural inlet/mechanical exhaust, mechanical inlet/natural exhaust, and fully mechanical. The document also discusses fan types, air filters, and design considerations to minimize mechanical ventilation needs.