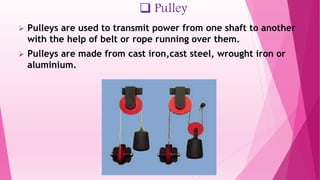

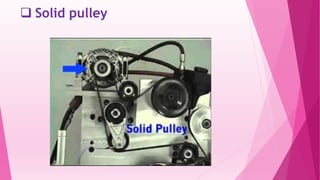

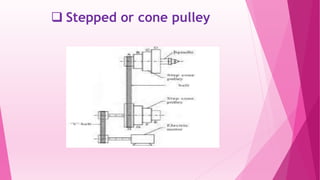

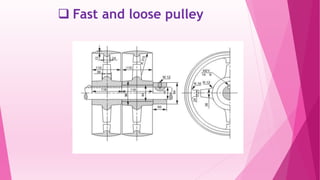

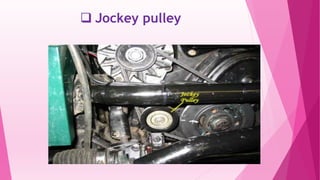

This document discusses the different types of pulleys. Pulleys are used to transmit power from one shaft to another using belts or ropes. The main parts of a pulley are the rim, hub, and arms. There are several types of pulleys including solid pulleys, split pulleys, stepped/cone pulleys, fast and loose pulleys, jockey pulleys, guide pulleys, and grooved pulleys. Solid pulleys are one piece while split pulleys can be taken apart. Stepped pulleys allow changing shaft speed. Fast and loose pulleys allow intermittent machine operation. Jockey, guide, and grooved pulleys are used for specific belt routing and grip purposes.