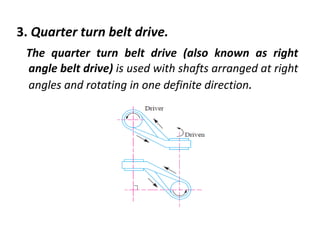

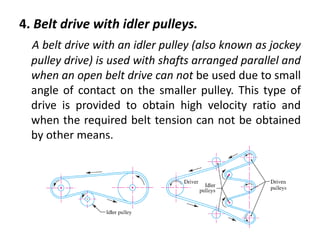

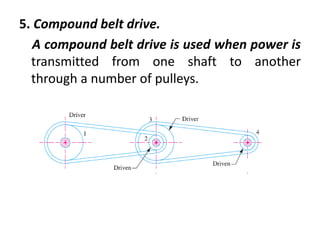

This document discusses the design of transmission systems. It covers various types of belt drives used to transmit power between shafts including flat belts, V-belts, circular belts, and discusses factors to consider when selecting a belt drive such as the power needs, shaft speeds and layout. It also describes types of flat belt drives, materials used for belts, and defines concepts like velocity ratio, slip and creep in belt drives.