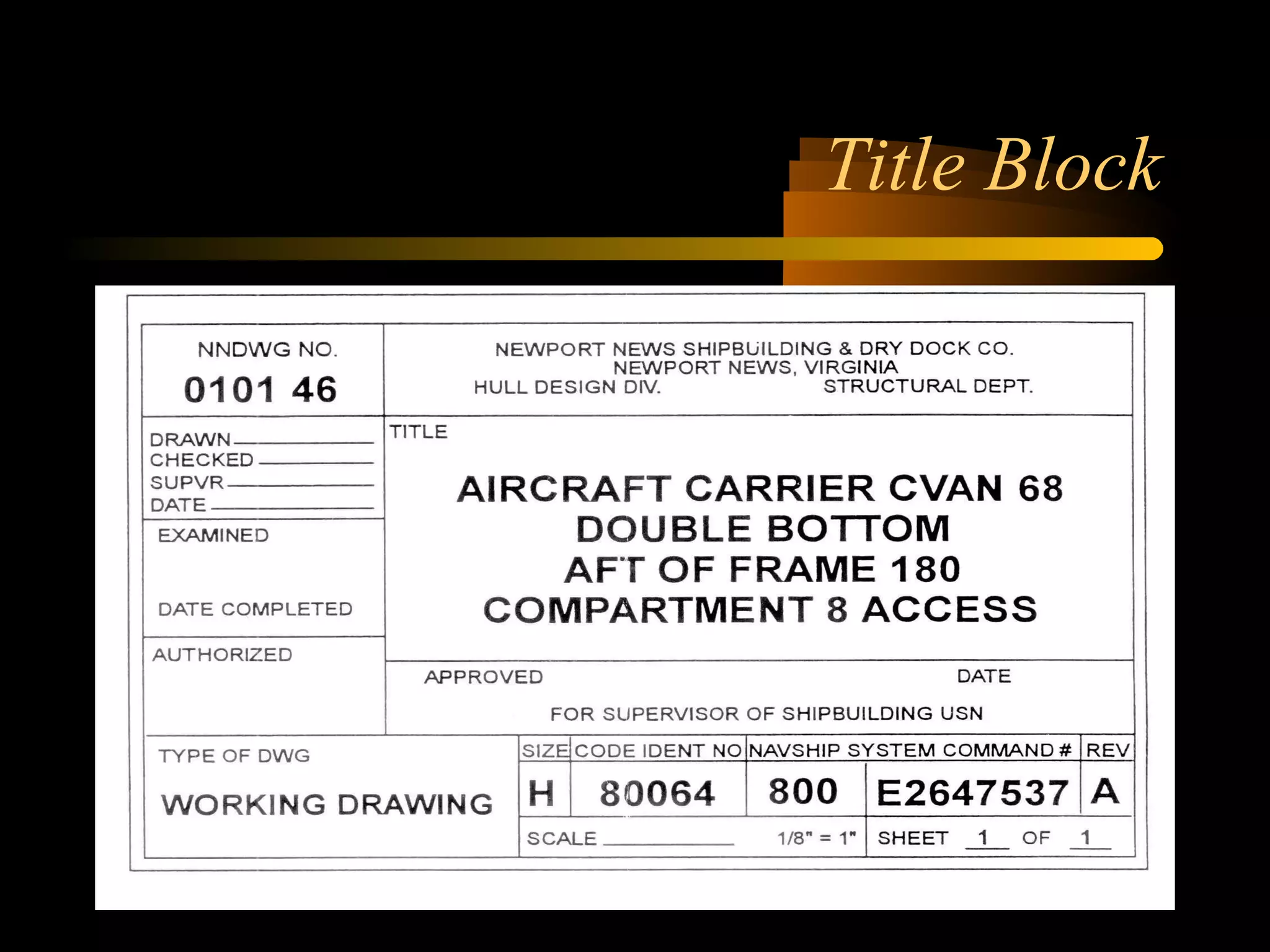

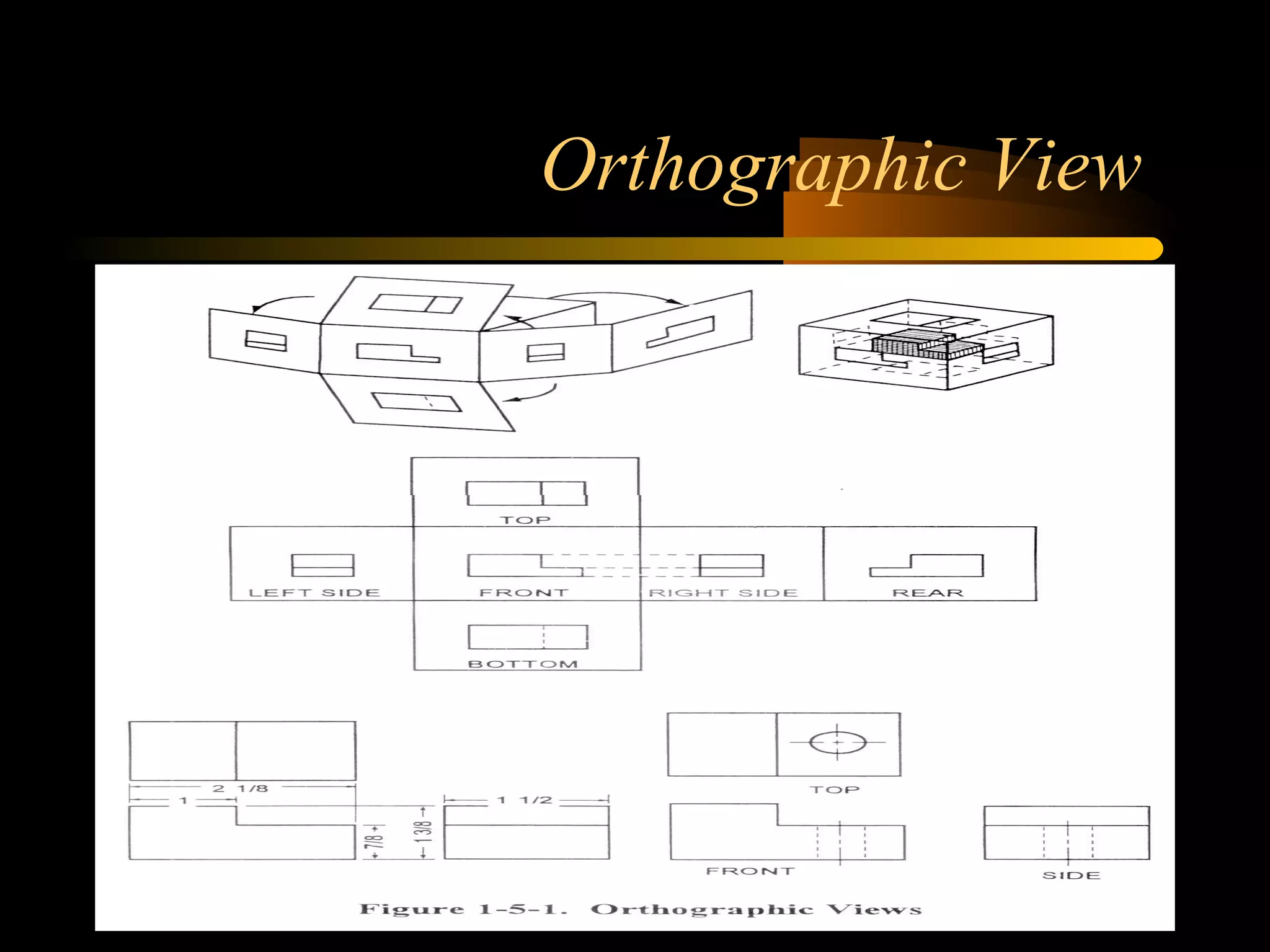

The document provides information on reading blueprints including locating title blocks, revision blocks, and bills of material. It describes how to use zone numbers to locate points and identifies common symbols, abbreviations, lines, dimensions, and views such as orthographic, section, and developed views used in blueprints.