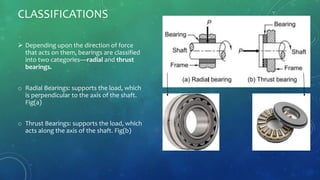

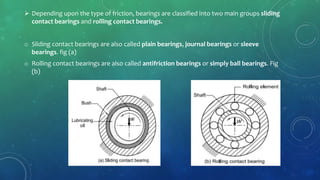

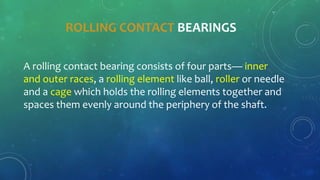

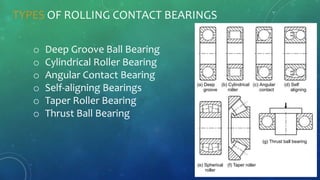

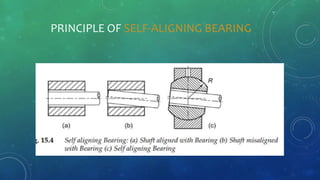

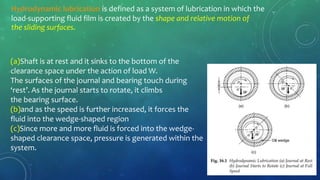

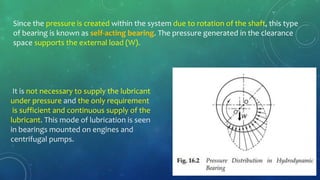

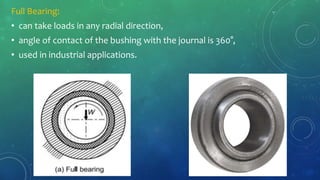

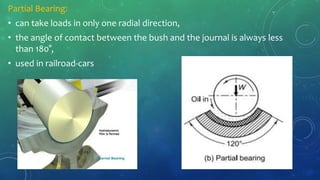

Bearings are mechanical elements that enable relative motion between parts while minimizing friction, supporting and holding shafts in position, and transmitting forces to the foundation. They are classified into radial and thrust bearings based on the direction of load, and further into sliding and rolling contact bearings. The selection of bearing types depends on various application requirements, including load conditions, speed, alignment, and lubrication methods.