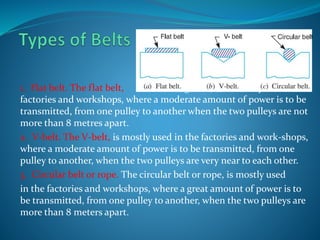

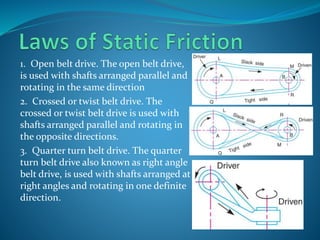

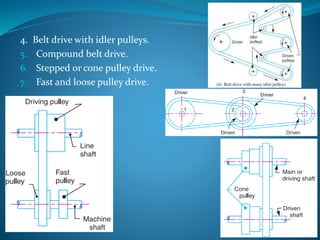

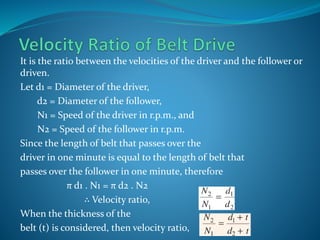

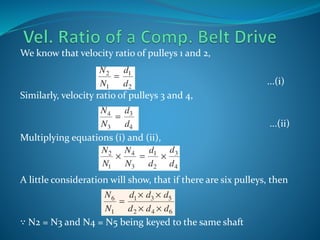

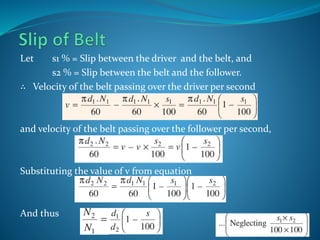

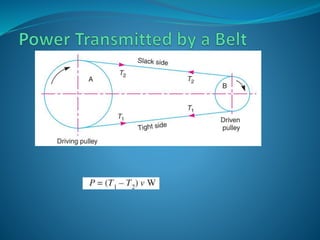

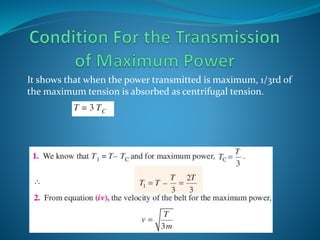

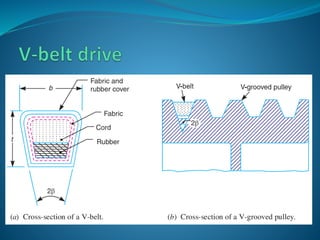

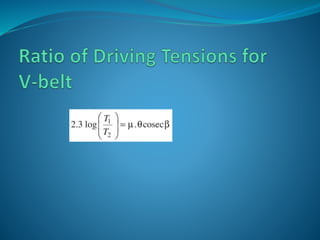

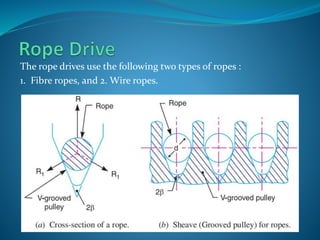

The document discusses different types of belt drives used to transmit power between rotating shafts, including flat belts, V-belts, circular belts, and rope drives. It covers factors that influence the amount of power transmitted, suitable applications for different belt types, advantages and disadvantages of V-belt drives, and advantages of using fibre ropes for rope drives.