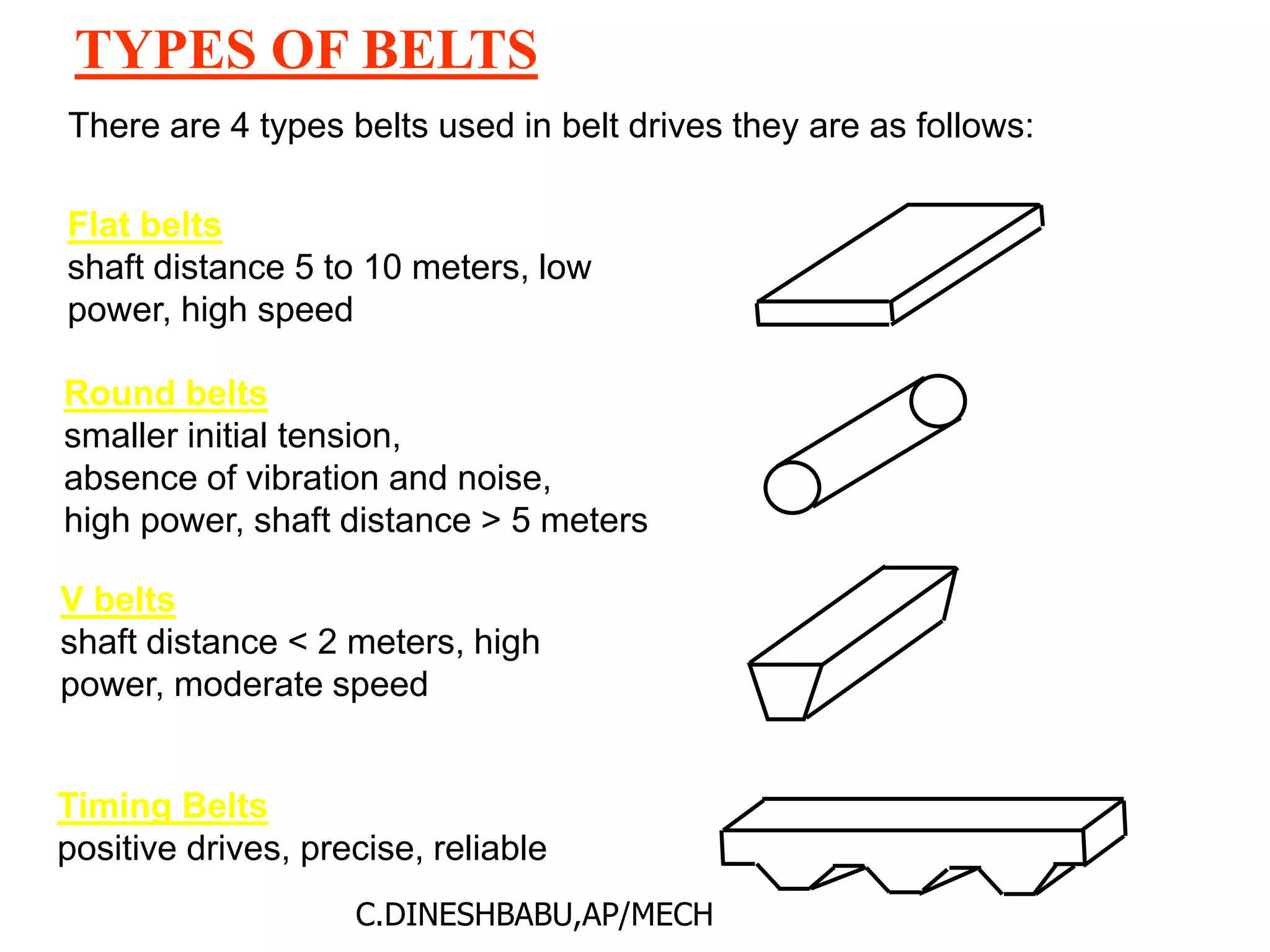

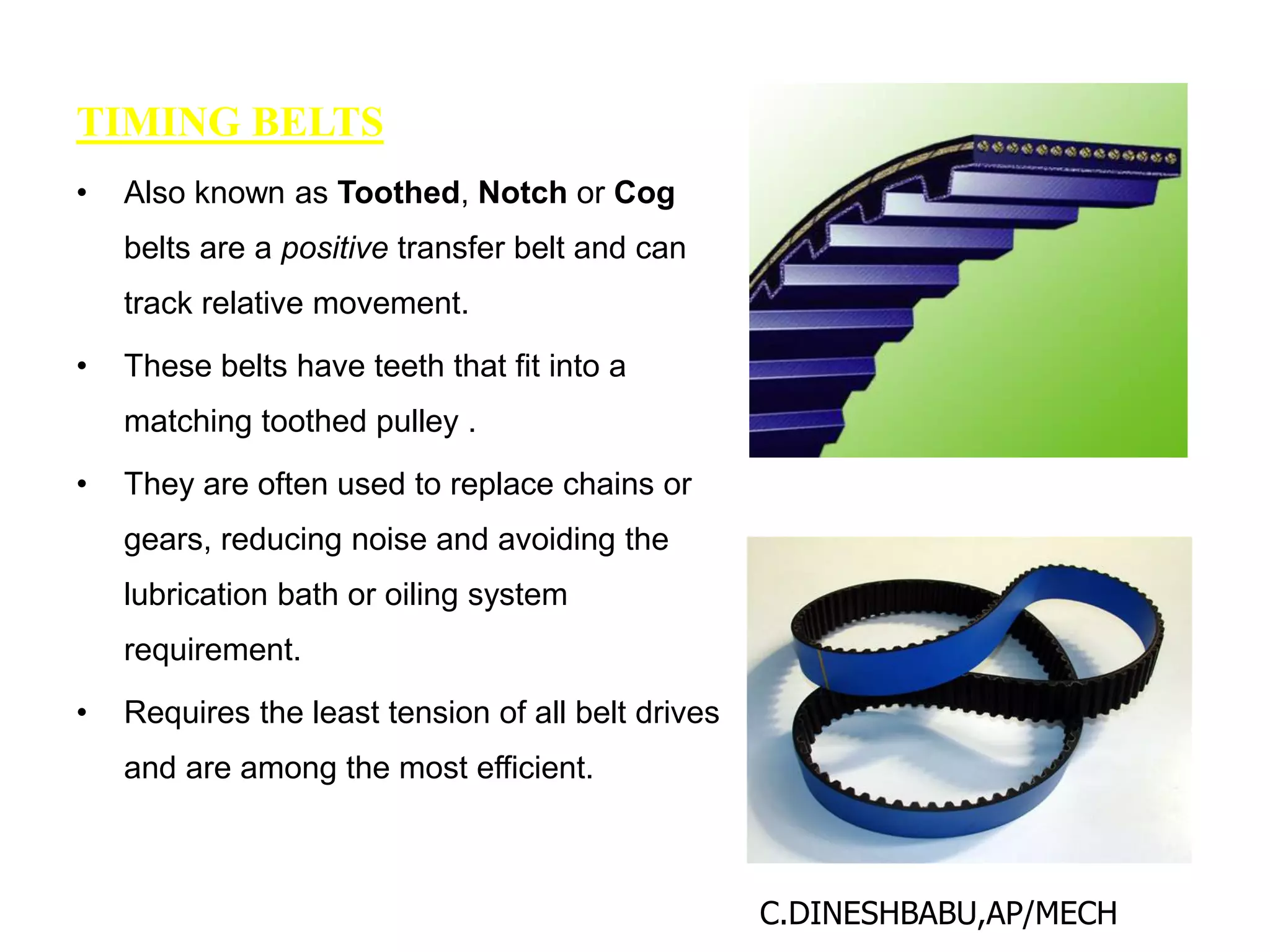

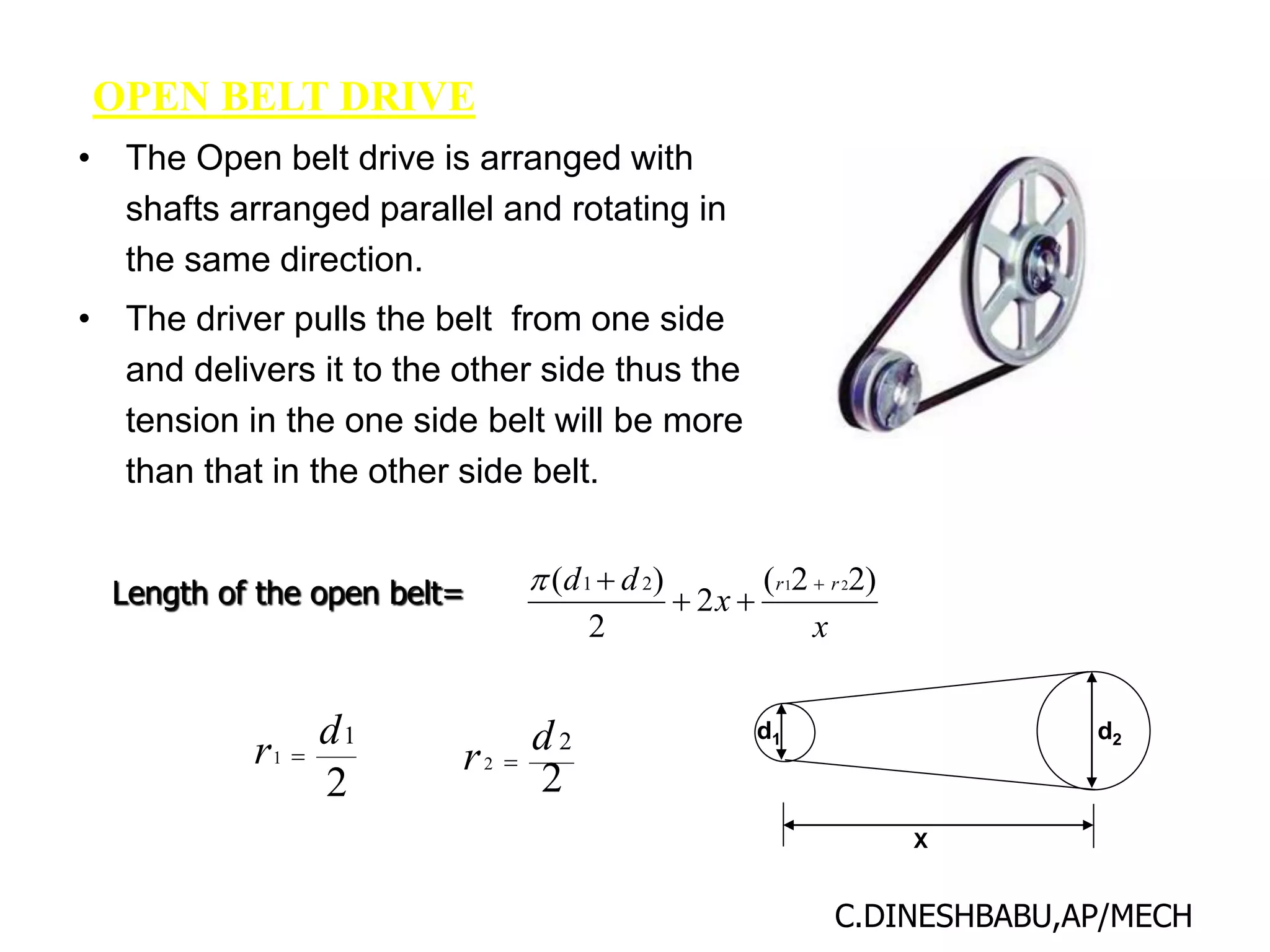

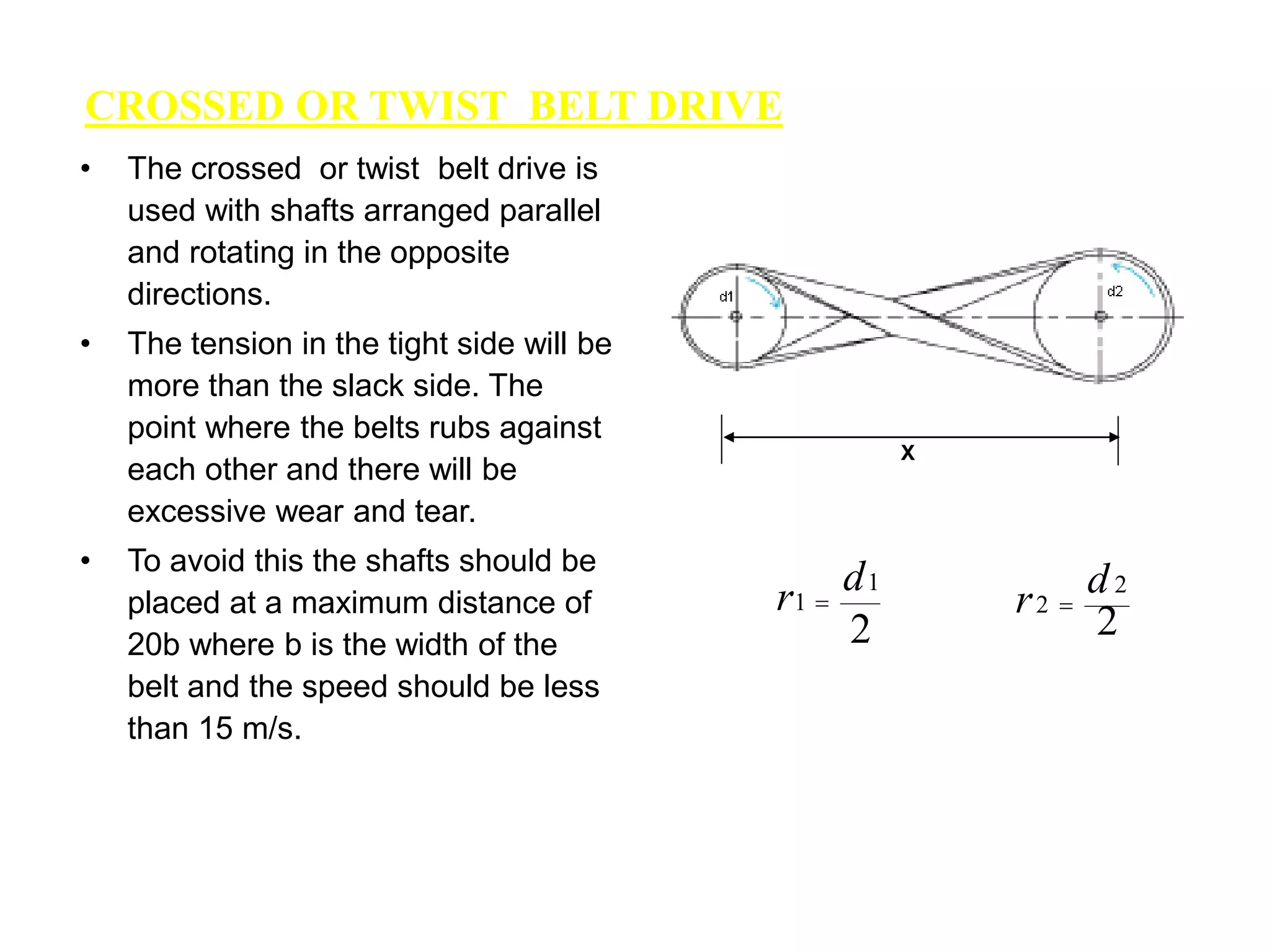

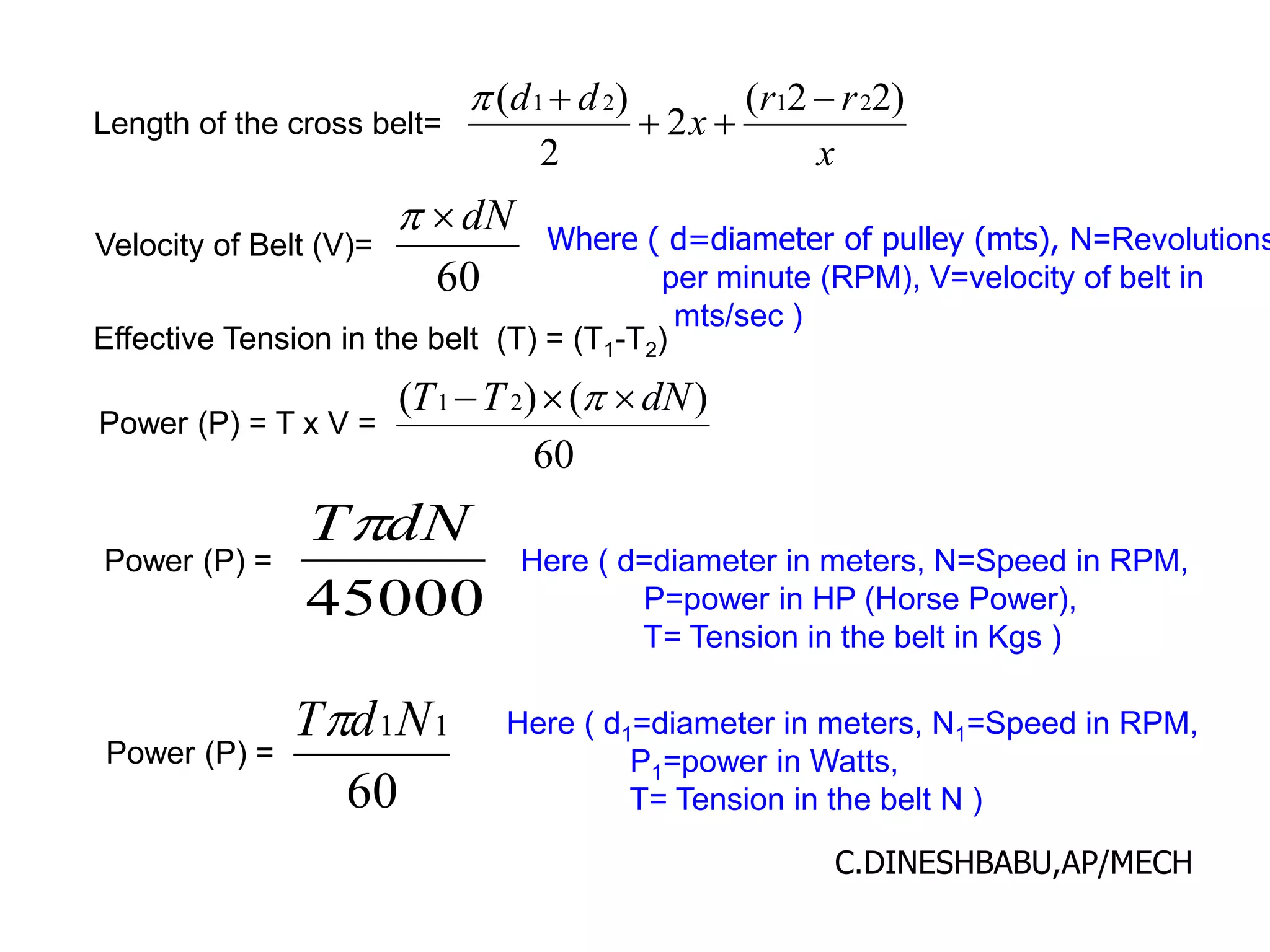

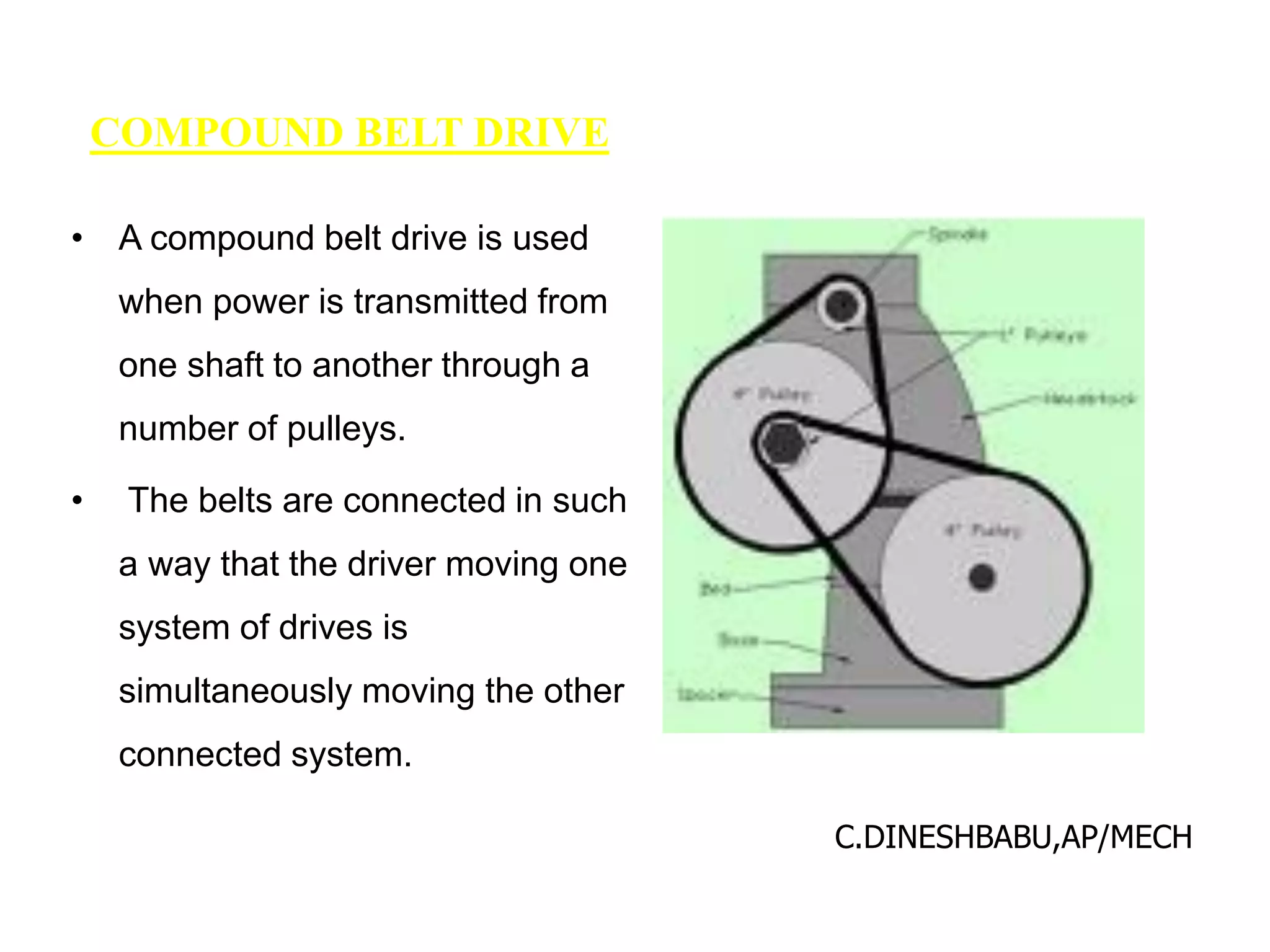

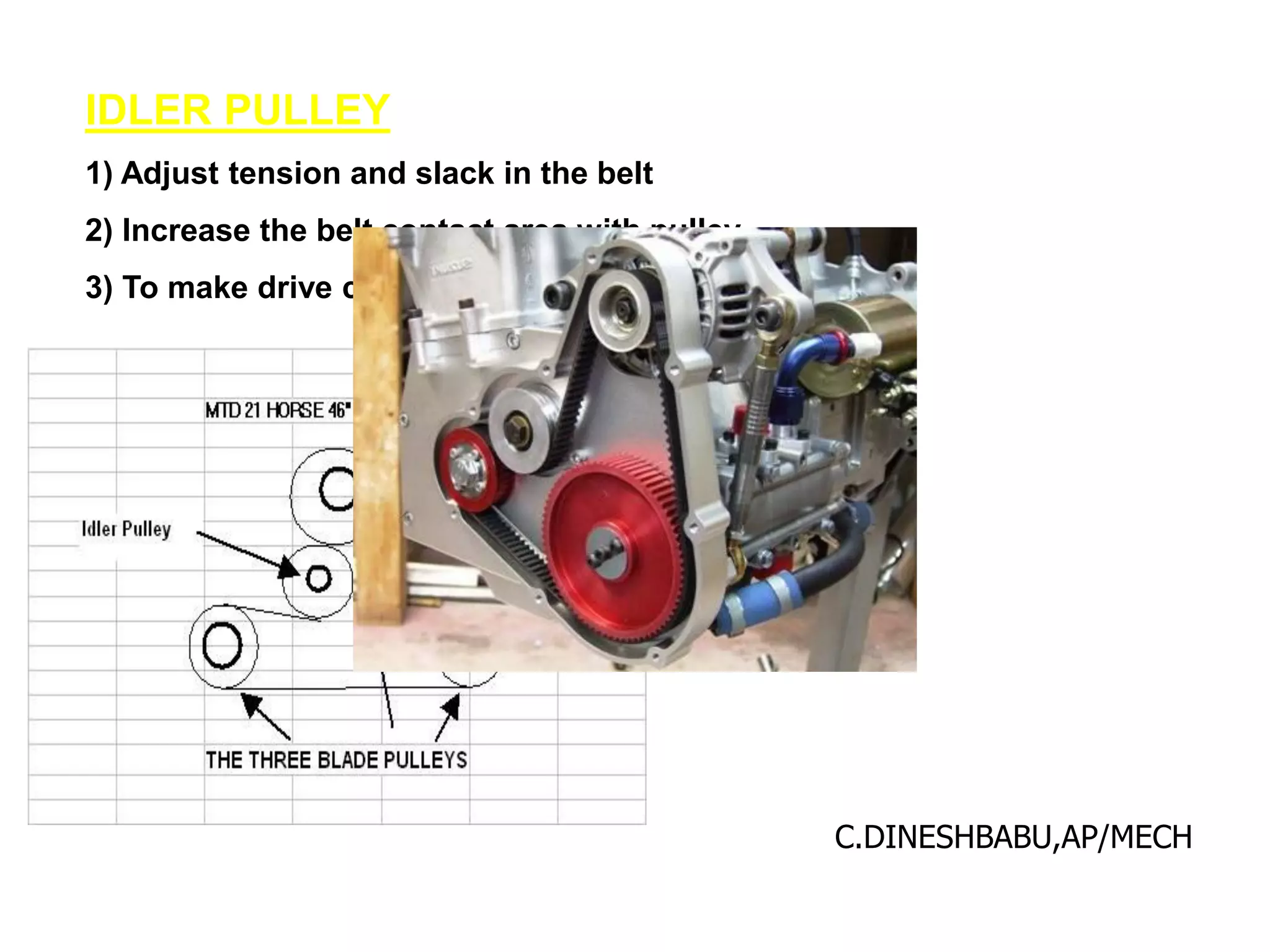

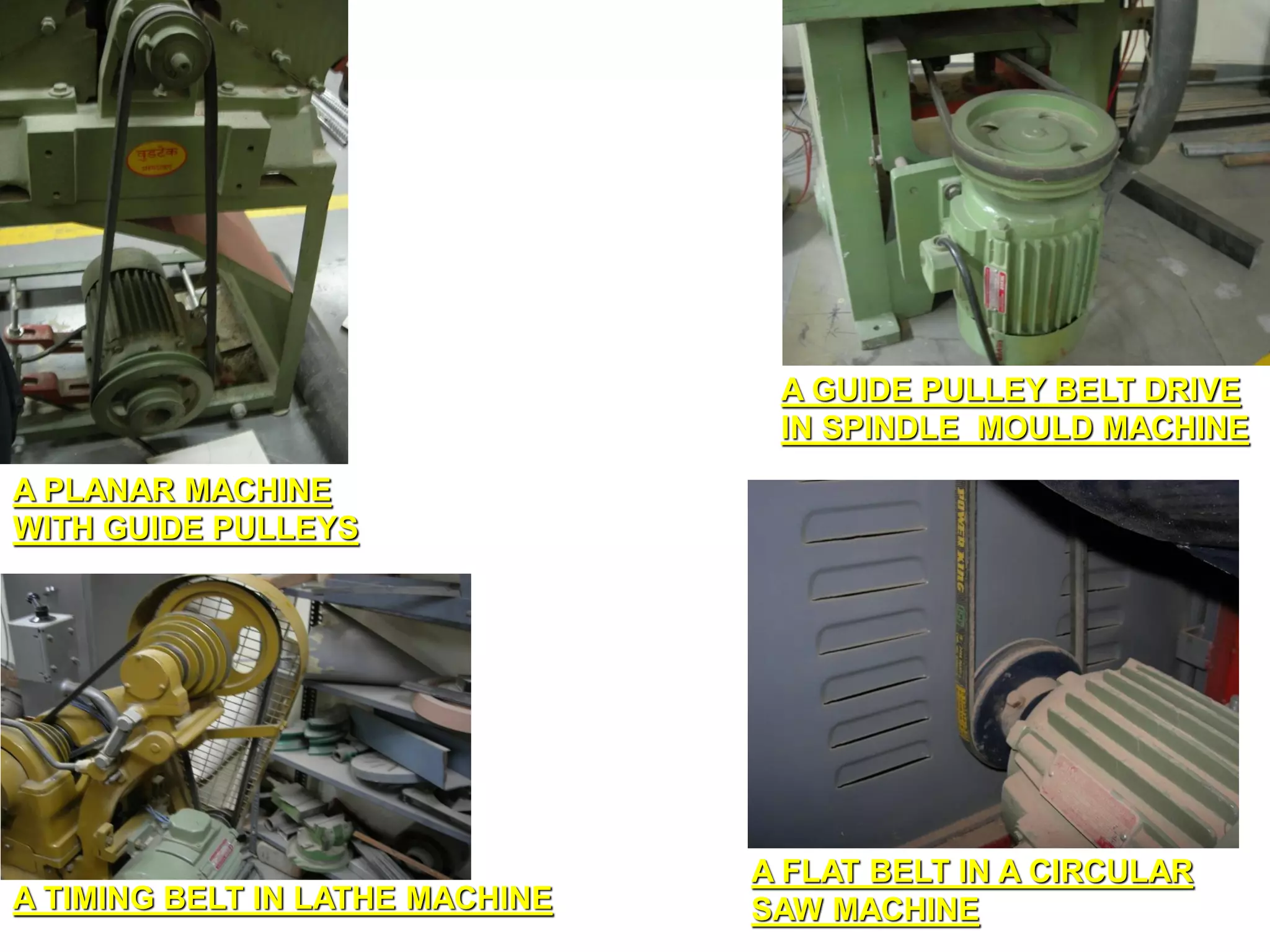

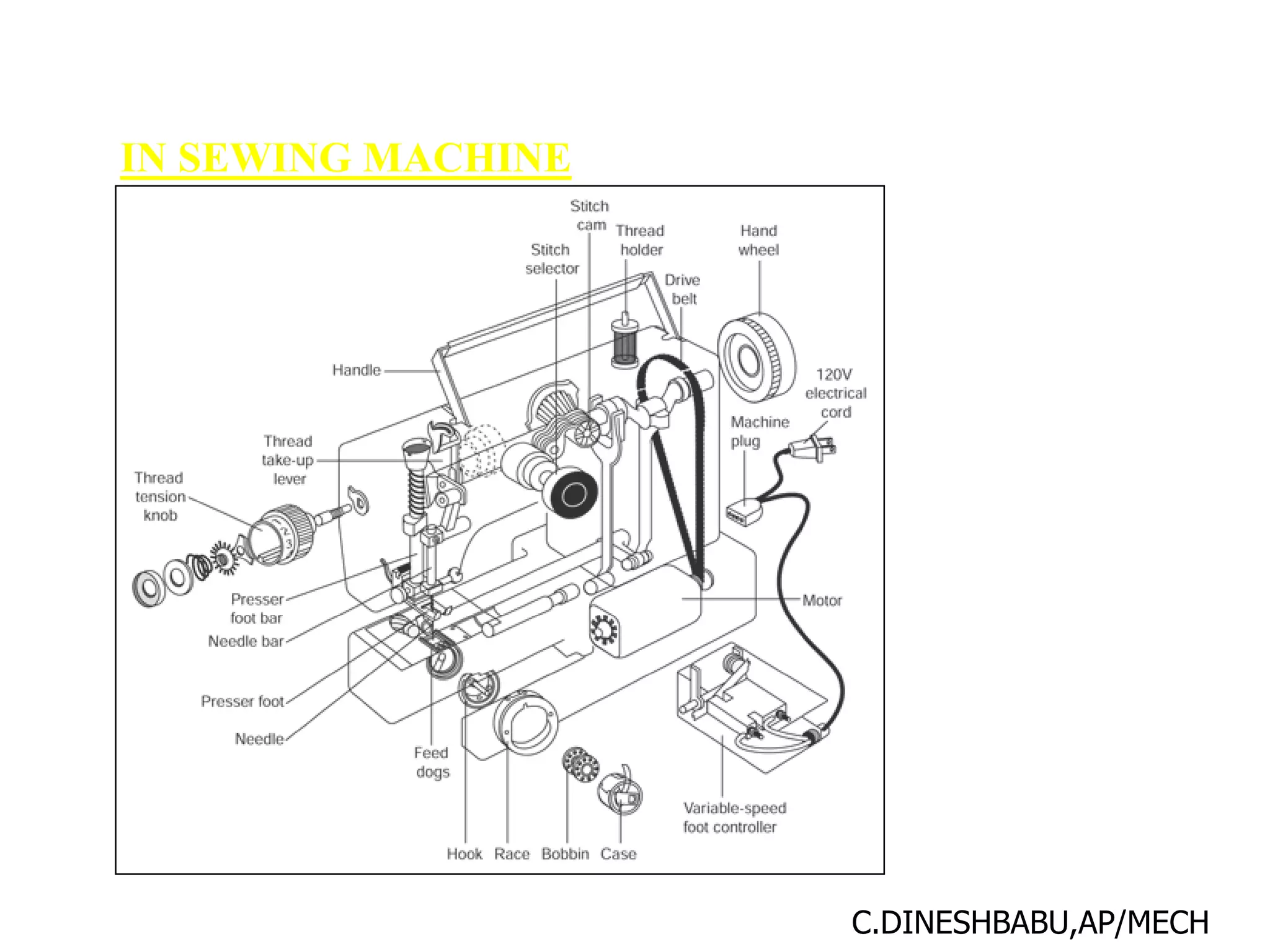

The document discusses different types of belt drives used to transfer rotational motion between two shafts. It describes four common types of belts - flat belts, round belts, V-belts, and timing belts. It also discusses different belt drive arrangements including open, crossed, compound drives. Key points covered include the characteristics and applications of each belt type as well as formulas for calculating belt drive power and tension.