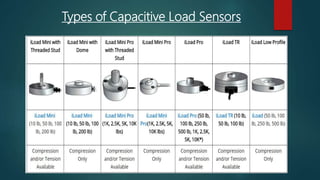

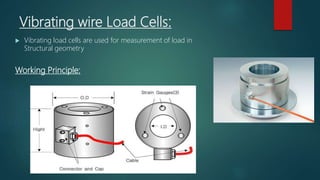

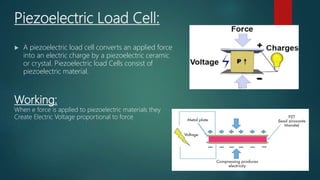

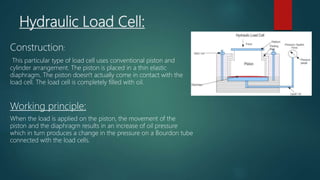

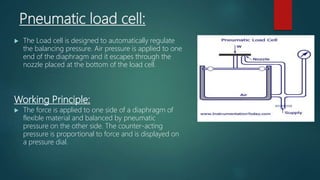

Load cells are transducers that convert an applied force into an electrical signal. There are several types of load cells including resistive, capacitive, vibrating wire, piezoelectric, hydraulic, and pneumatic. Resistive load cells use strain gauges to measure deformation from applied forces. Capacitive load cells measure deformation capacitively. Vibrating wire load cells monitor loads in structural elements. Piezoelectric load cells generate voltage when force is applied to piezoelectric materials. Hydraulic load cells use fluid pressure from piston movement to measure force. Pneumatic load cells balance applied force with counteracting air pressure.