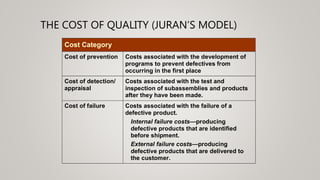

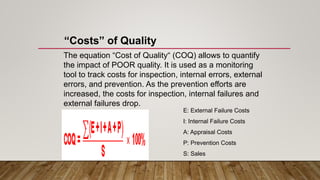

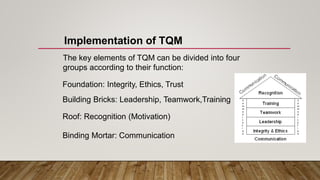

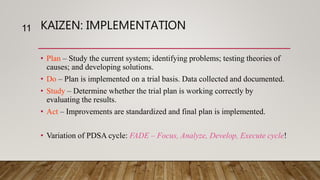

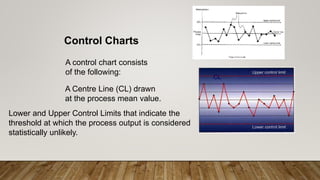

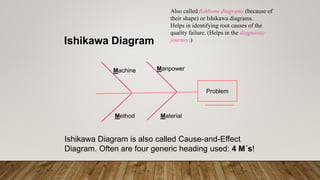

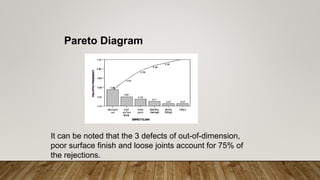

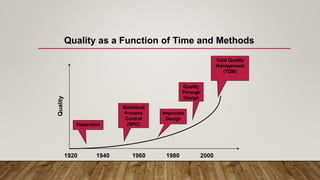

This document provides an overview of total quality management (TQM). It defines TQM and discusses its benefits such as improved quality, increased productivity, lower costs and business growth. It also describes Juran's model of the costs of quality, including prevention costs, appraisal costs, and failure costs. Additionally, the document outlines key elements of TQM like leadership, employee involvement, customer focus, and continuous improvement. Finally, it introduces several quality tools used in TQM, including check sheets, histograms, control charts, Pareto diagrams, and Ishikawa diagrams.