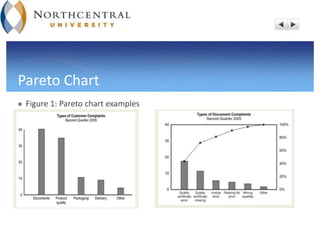

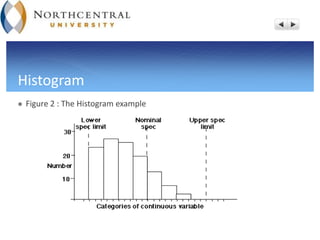

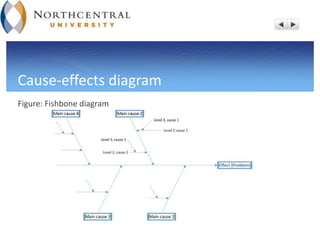

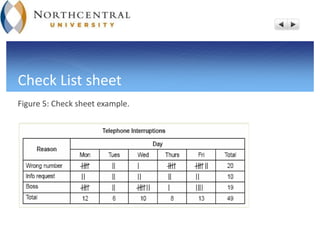

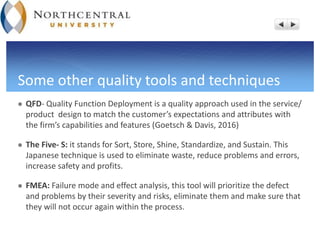

The document discusses various quality management tools and techniques, including Pareto charts, histograms, cause-effect diagrams, flowcharts, check sheets, scatter diagrams, and control charts. It explains how each tool is used to identify and address issues that impact quality, costs, and process performance in order to continually improve processes and products/services. Implementing these tools effectively as part of a total quality management system can help organizations reduce waste, lower costs, enhance quality, and gain a competitive advantage.