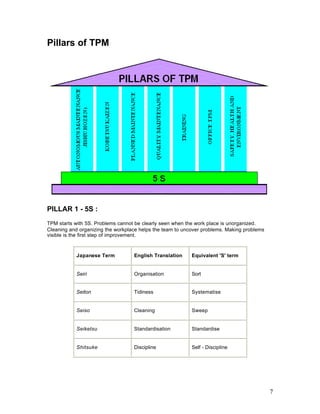

Total Productive Maintenance (TPM) is a maintenance program that aims to maximize production by involving all employees in maintenance. The goals of TPM are to increase production while also improving employee morale and satisfaction. It was introduced in Japan in the 1950s and 1960s and focuses on increasing equipment effectiveness through strategies like autonomous, predictive, and preventative maintenance. TPM aims for goals like minimizing breakdowns, achieving high equipment availability and overall equipment effectiveness, reducing costs, and satisfying customers. It provides benefits such as increased productivity, reduced defects, lower costs, and an improved work environment and employee attitudes.