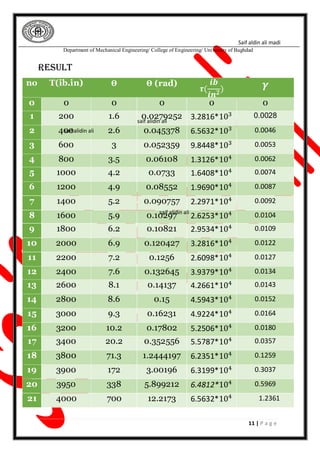

The document presents a torsion test experiment aimed at studying the elastic behavior of metallic materials, specifically mild steel and cast iron, under twisting forces. It details the objective, procedure, calculations, and results of the experiment, including the determination of shear modulus and shear stress at yield. Additionally, it discusses the fracturing mechanism and applications of torsion in mechanical equipment.

![Saif aldin ali madi

Department of Mechanical Engineering/ College of Engineering/ University of Baghdad

1 | P a g e

[MECHANICS OF MATERIALS Laboratory II]

University of Baghdad

Name: - Saif Al-din Ali -B-](https://image.slidesharecdn.com/torsiontesdt-190210123425/85/Torsion-test-1-320.jpg)