1. The document describes the design of a gear box including specifications, calculations of gear ratios and sizes, material selection, and shaft design.

2. Key specifications include delivering 27.6 hp at input speed of 1992 rpm and output speed of 103 rpm. Gears and bearings are designed to last over 13,000 hours.

3. Calculations determine the number of teeth for each gear and gear ratios. Materials including various grades of steel are selected for gears and shafts based on bending and wear stresses.

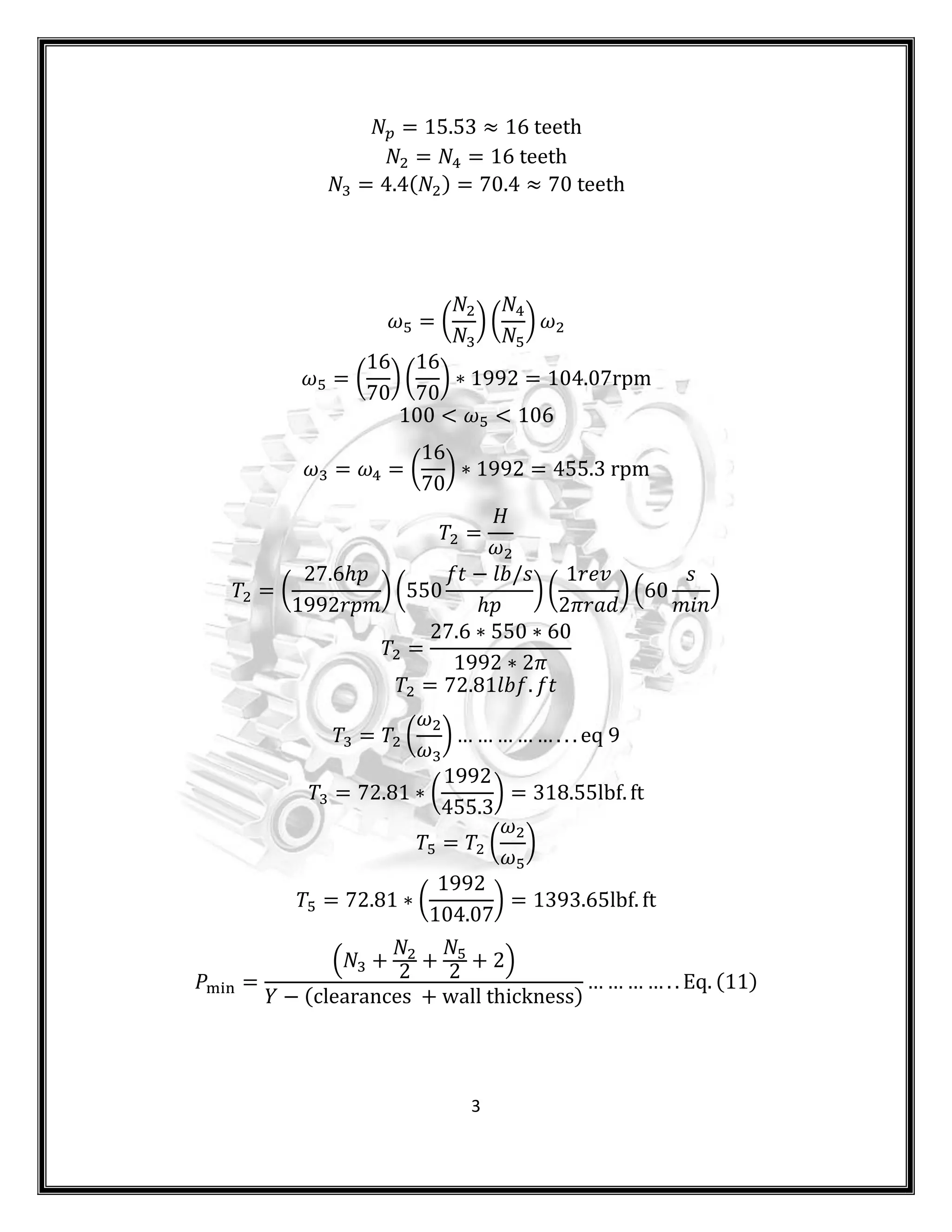

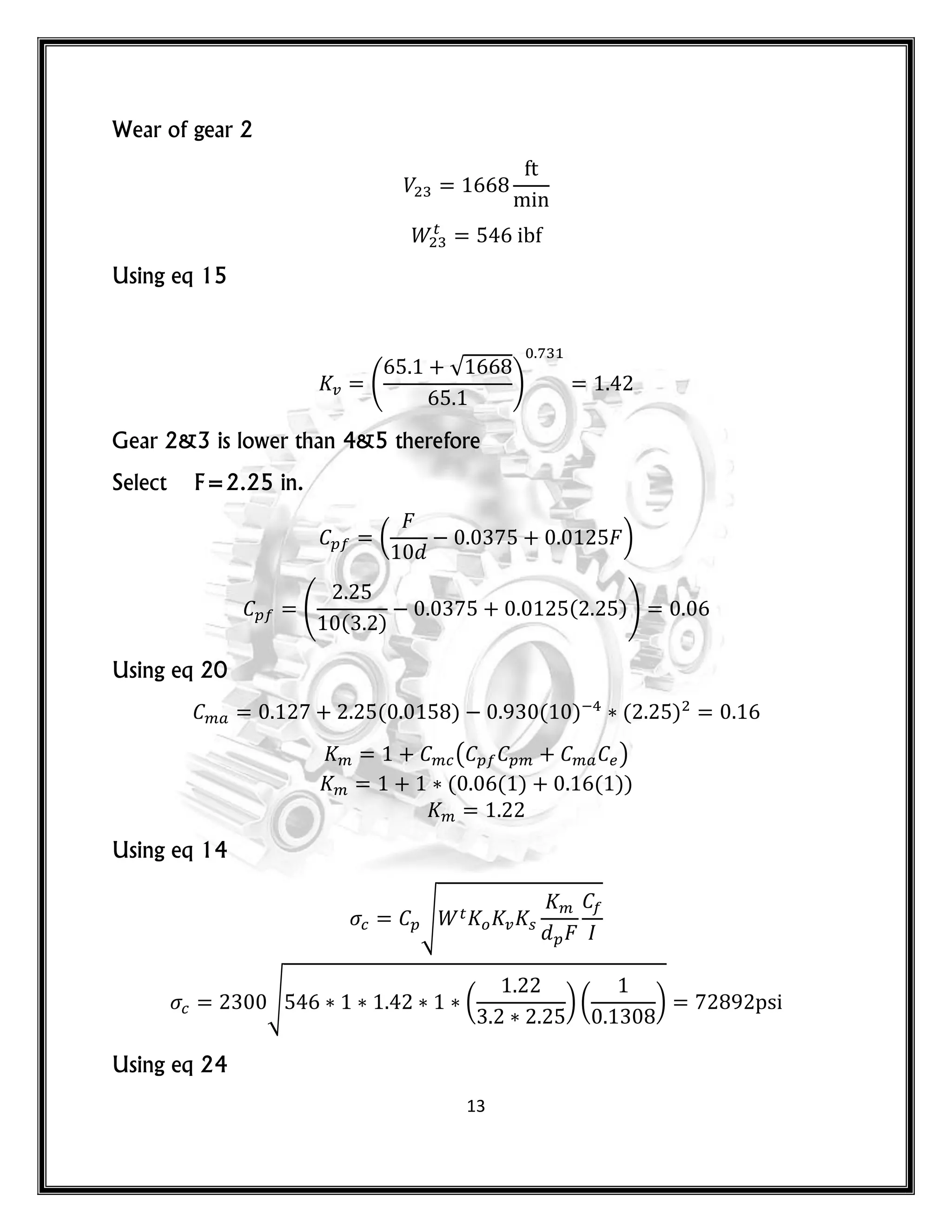

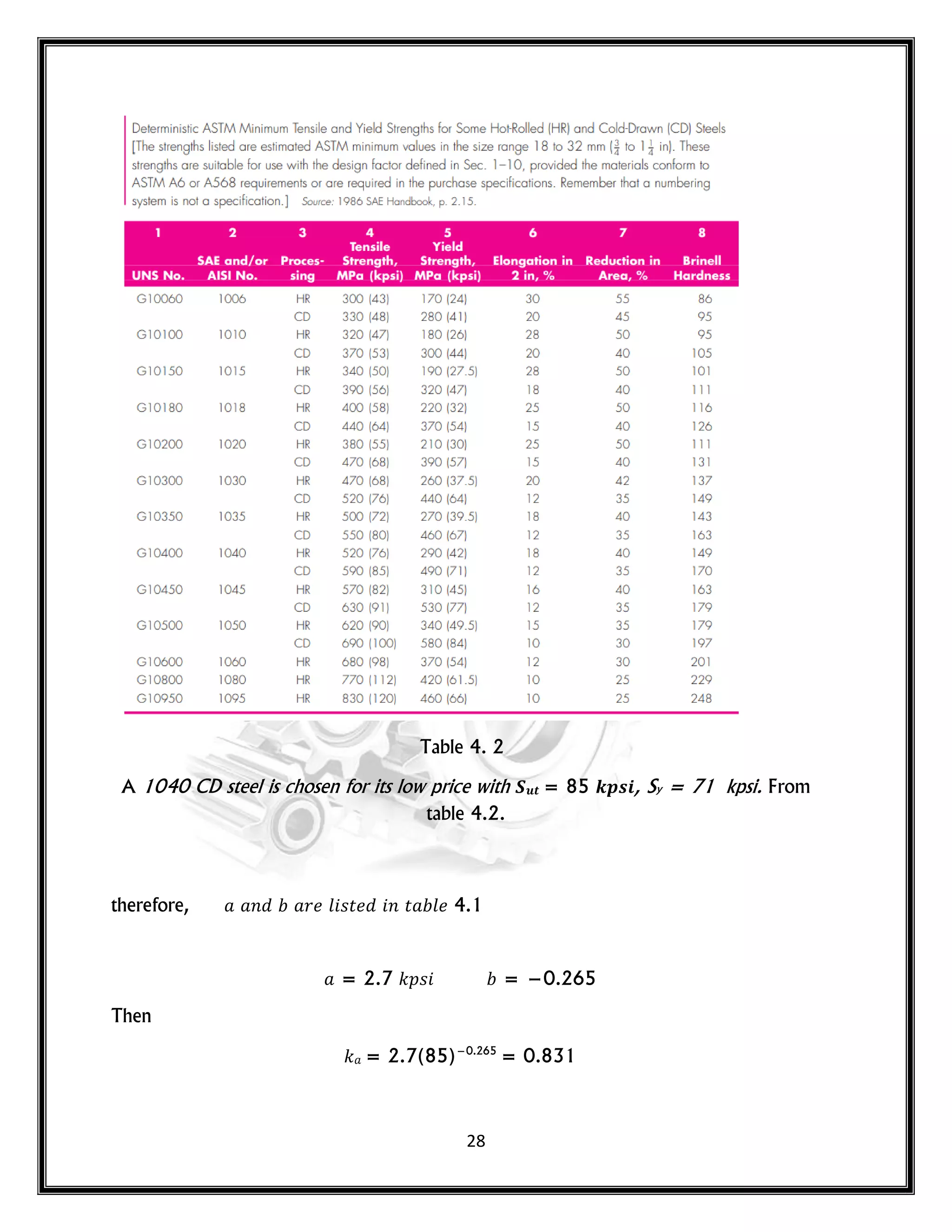

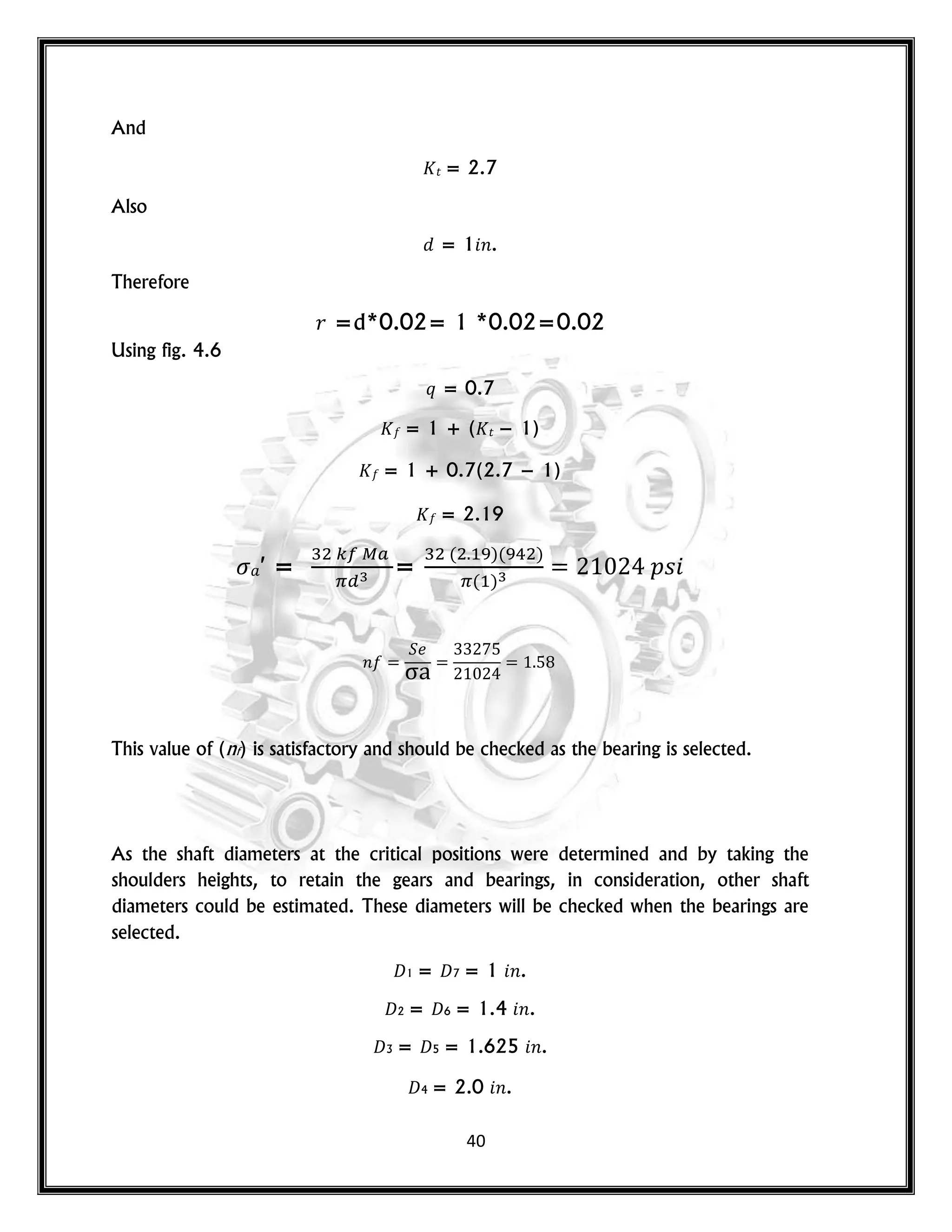

![20

0 0

3822 3822

0 0

0

500

1000

1500

2000

2500

3000

3500

4000

4500

y

[in.]

x [in.]

torque diagram](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-20-2048.jpg)

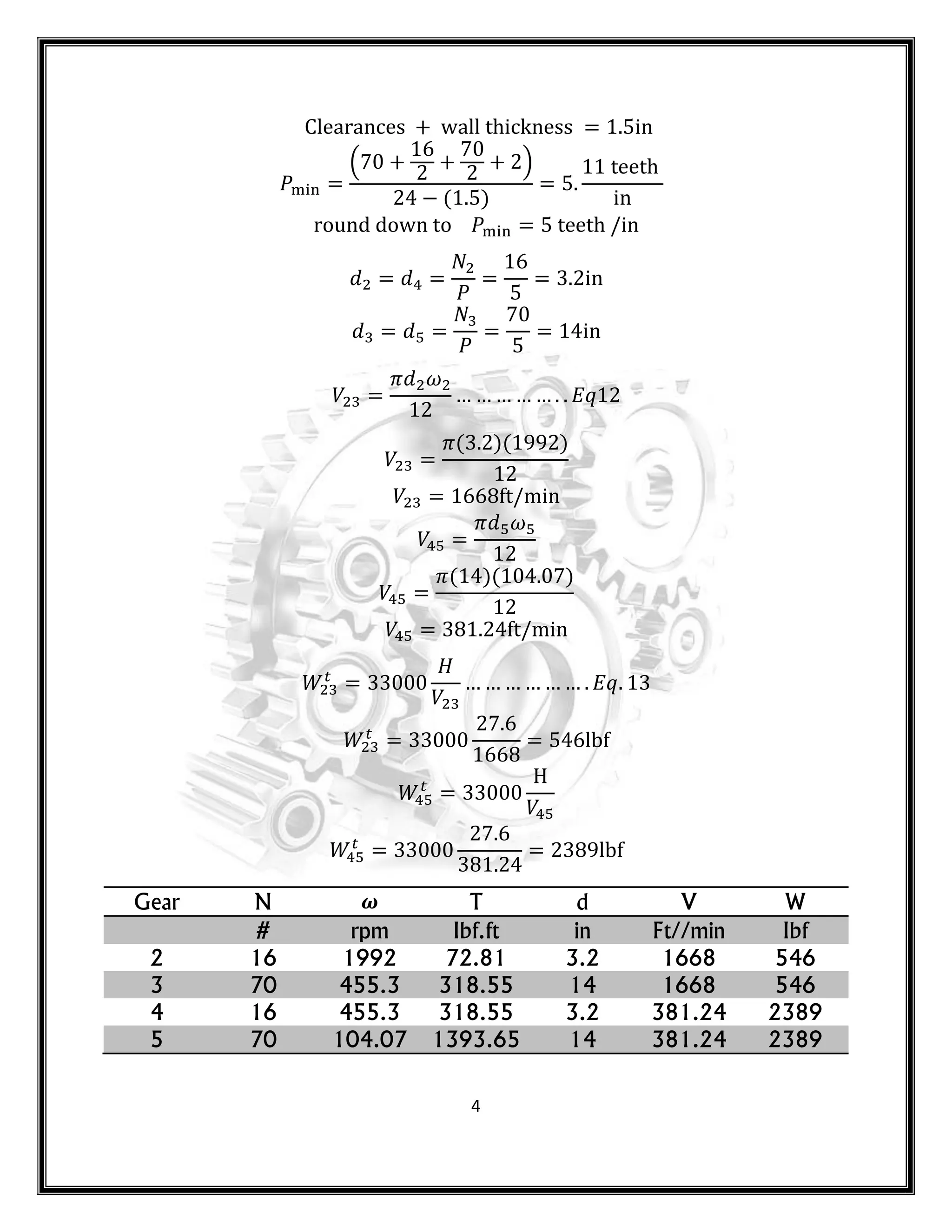

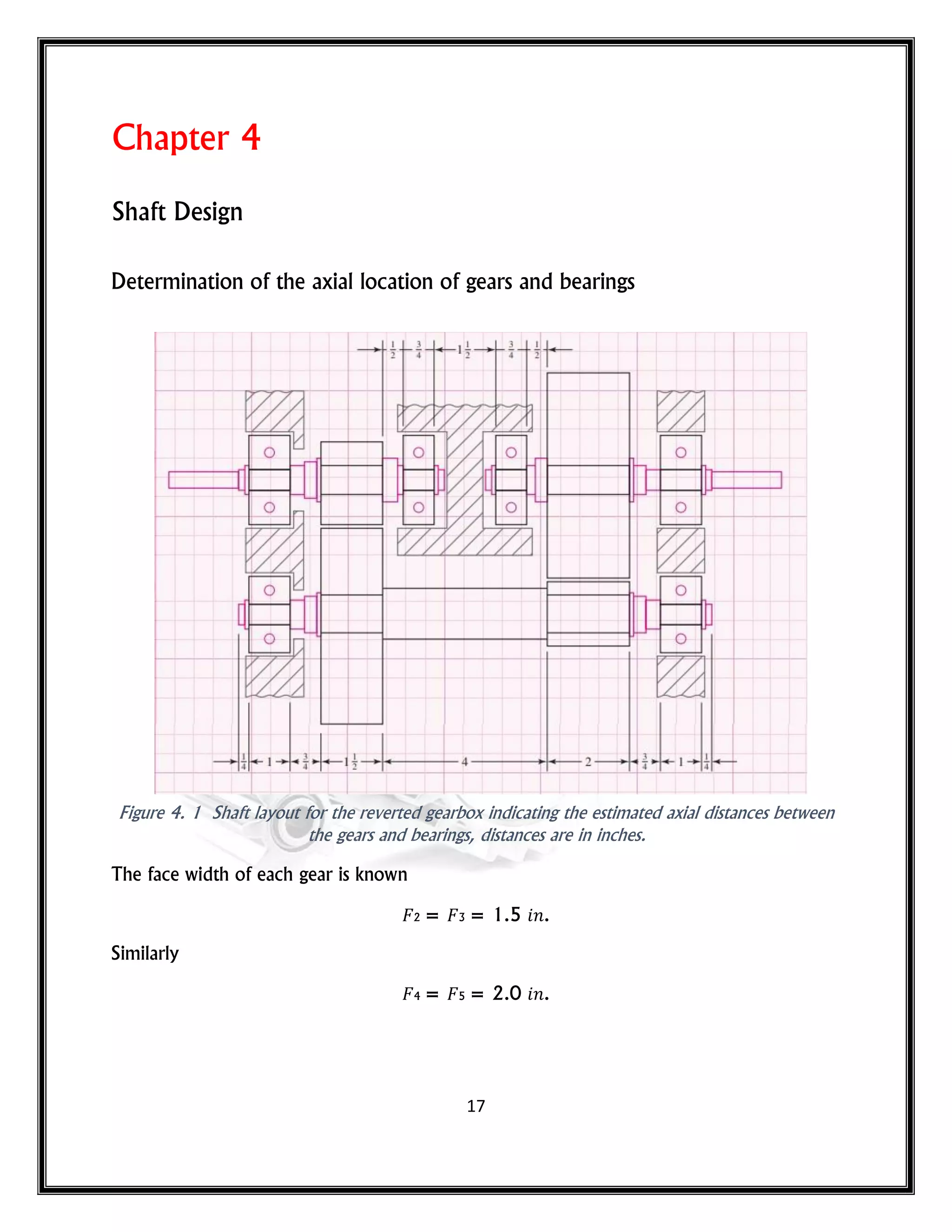

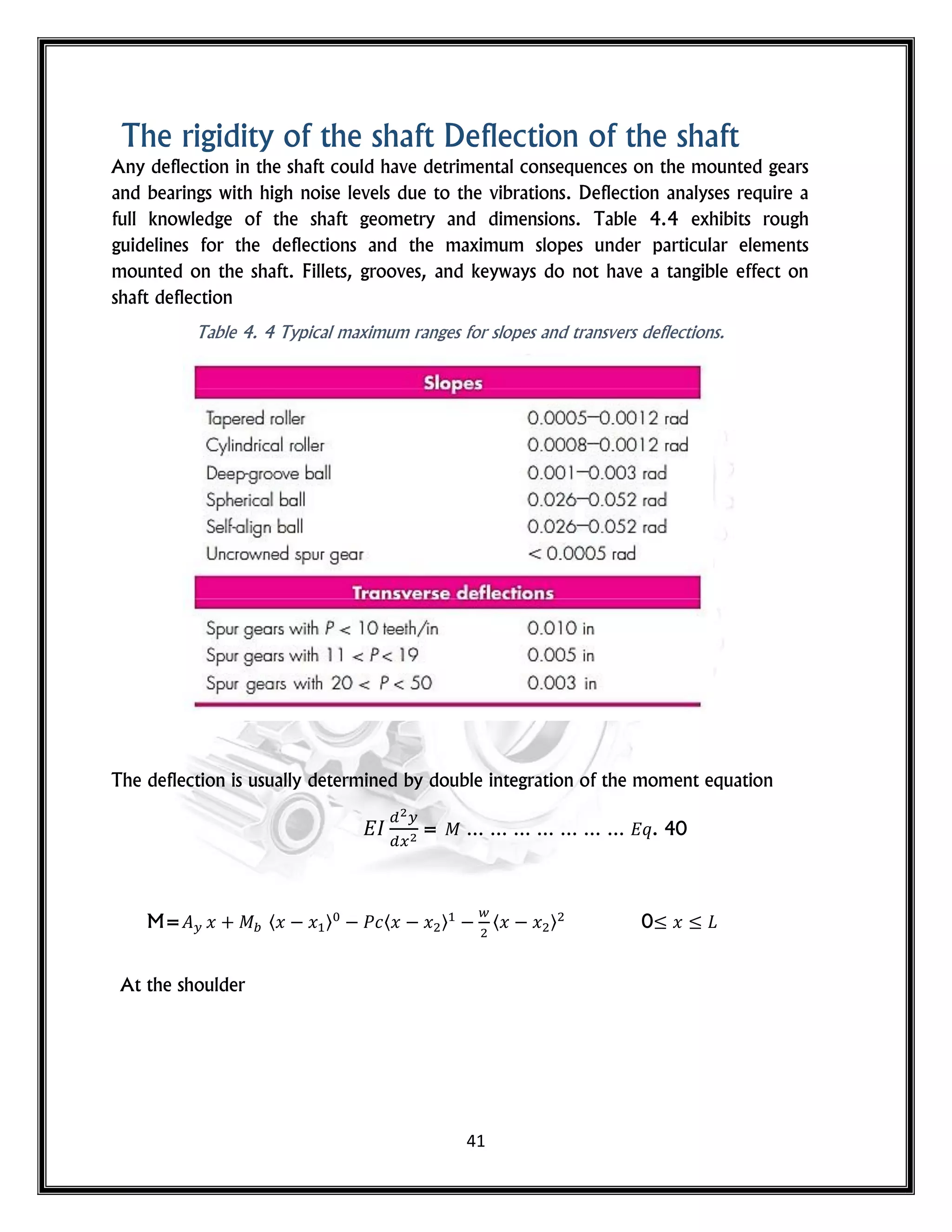

![21

101 101

647 647

-1742 -1742

0

-2000

-1500

-1000

-500

0

500

1000

y

[in.]

x [in.]

shear force diagram

0

202

3275

3922

2180

0

0

500

1000

1500

2000

2500

3000

3500

4000

4500

y

[in.]

x [in.]

moment diagram(x -z)](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-21-2048.jpg)

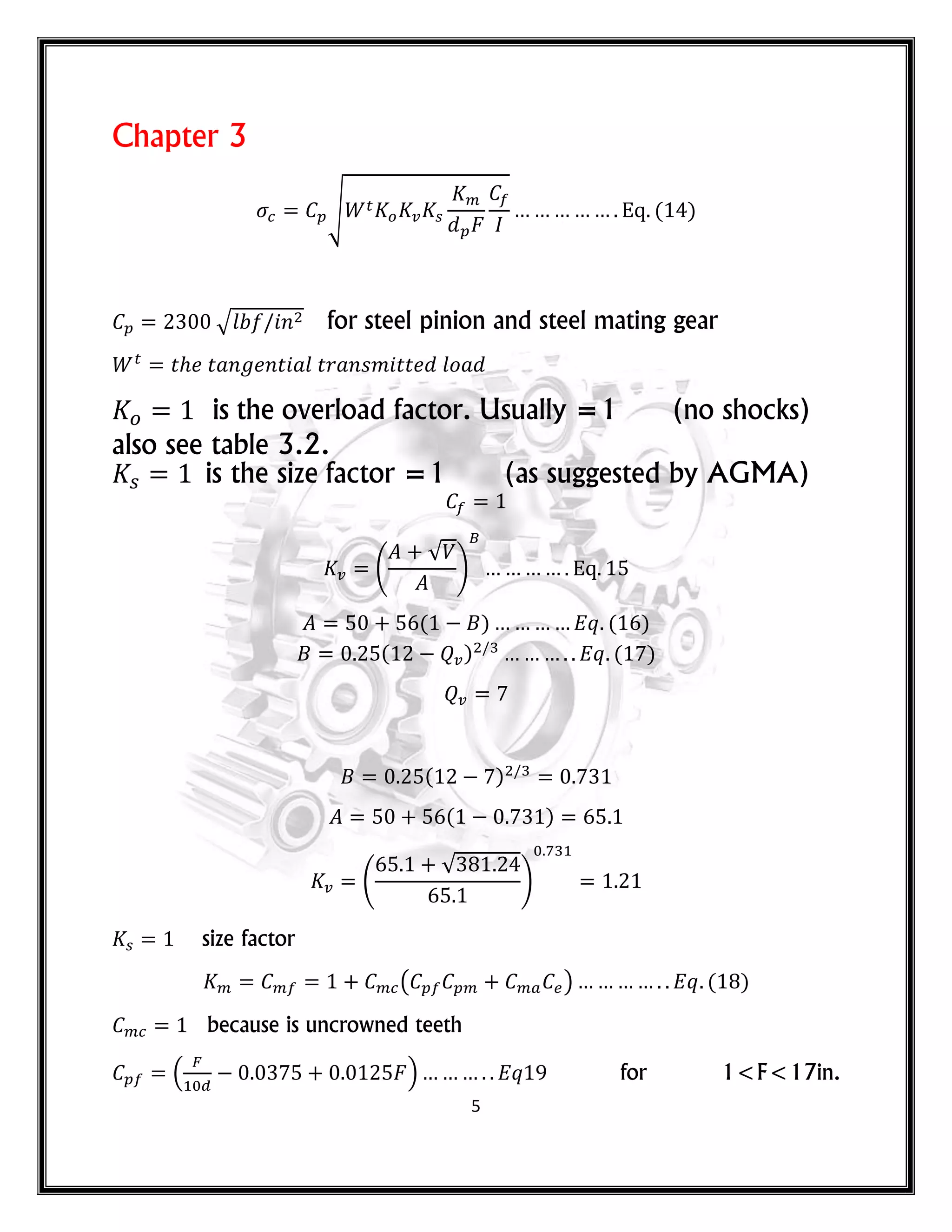

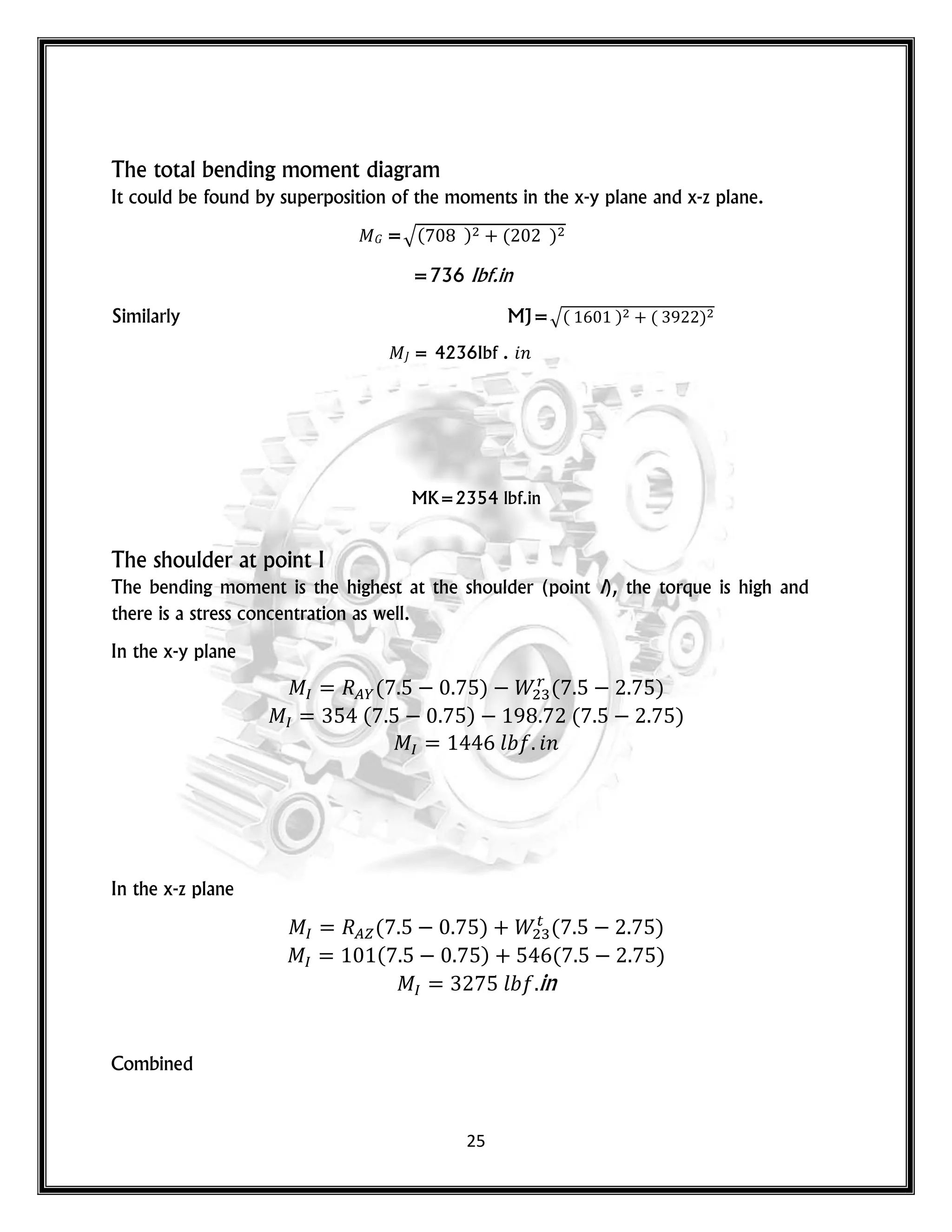

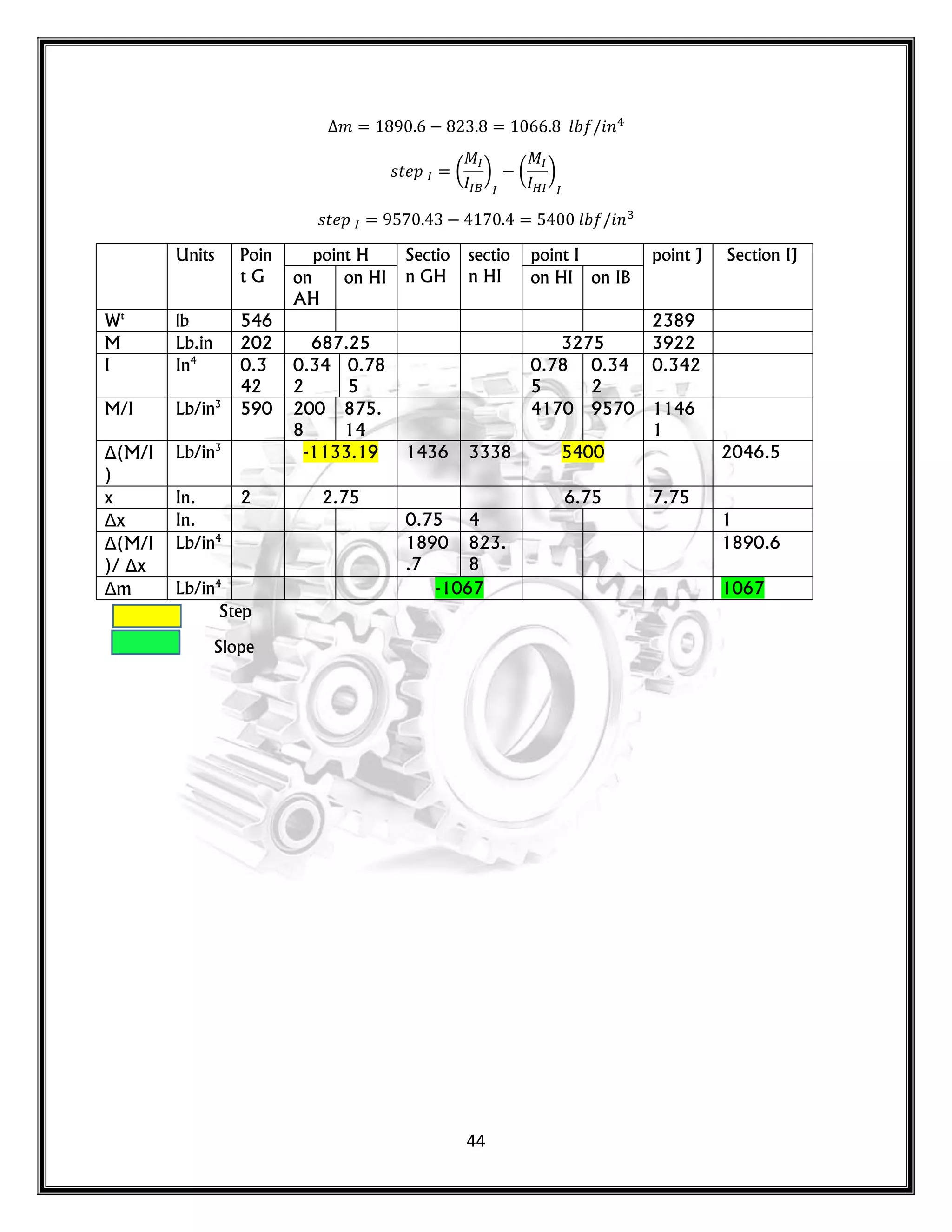

![22

354 354

155.28 155.25

-714.22 -714.22

0

-800

-600

-400

-200

0

200

400

600

y

[in.]

x [in.]

shear force diagram(x -y)

0

708

1446

887

0

0

200

400

600

800

1000

1200

1400

1600

y

[in.]

x [in.]

moment diagram(x -y)

0

736

3580

4236

2354

0

0

500

1000

1500

2000

2500

3000

3500

4000

4500

y

[in.]

x [in.]

moment diagram(x -y)](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-22-2048.jpg)

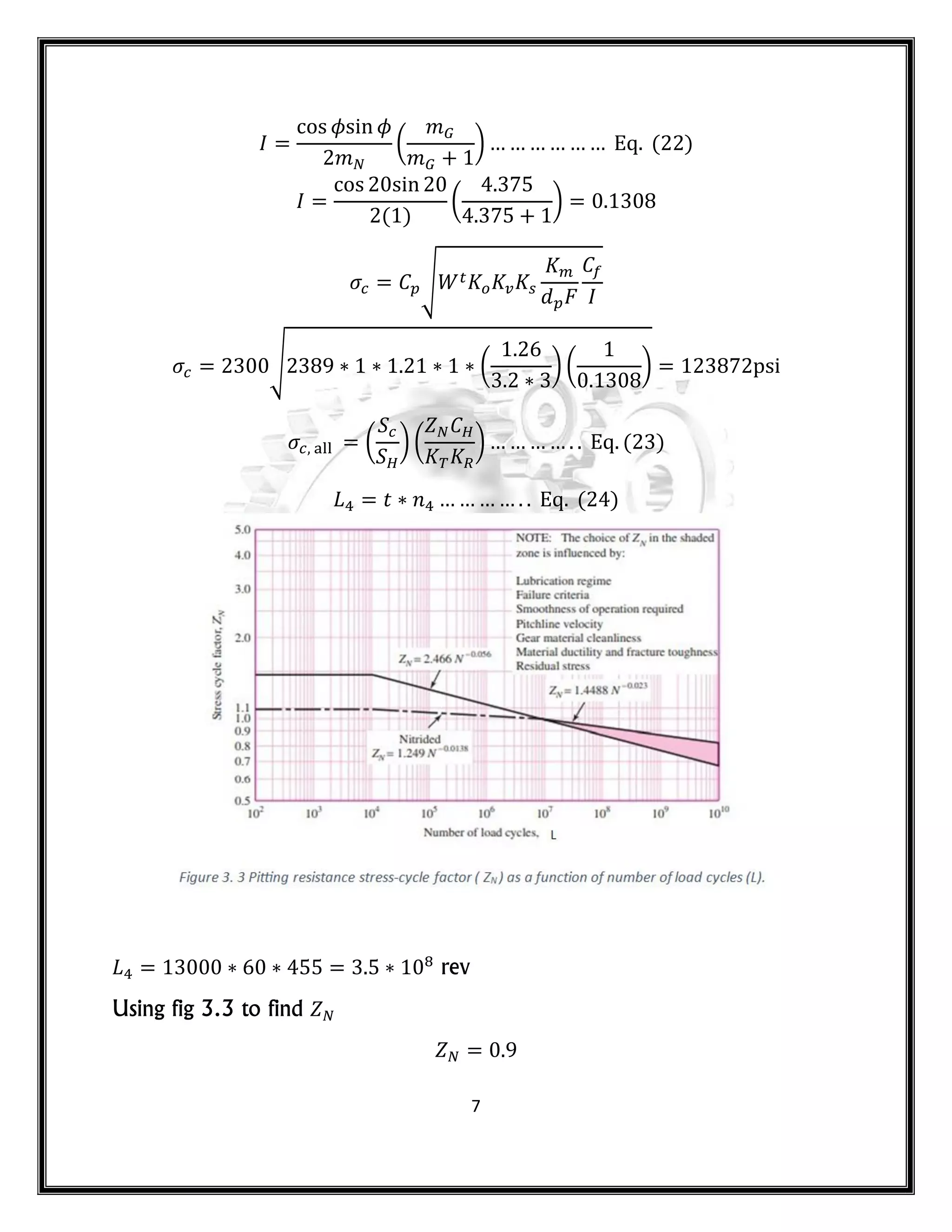

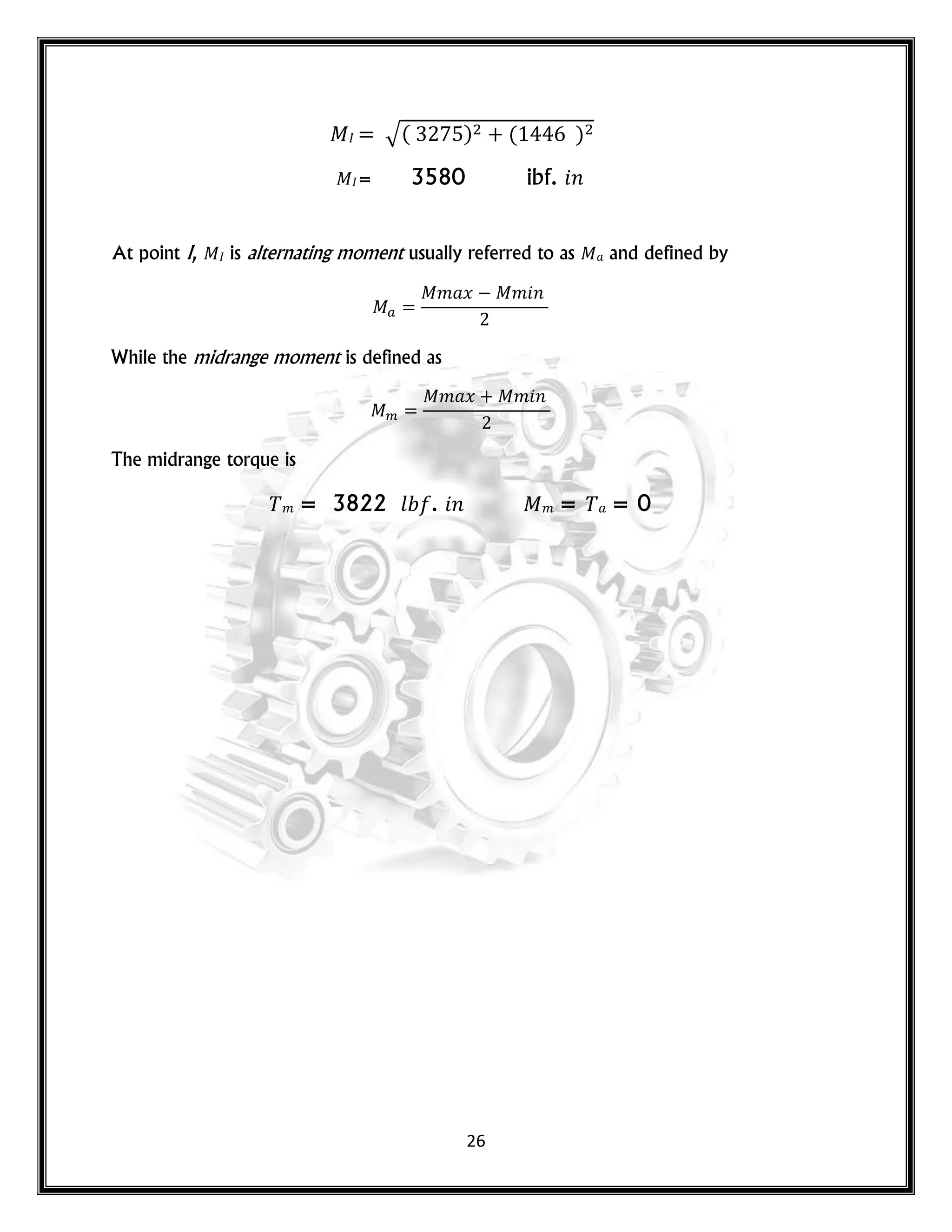

![33

The von Mises maximum stress is :

𝑚 𝑥′= [( 𝑚 + )2 + 3( 𝑚 + )2]1⁄2

*(

𝑘 ( 𝑚 )

) (

𝑘 𝑠( 𝑚 )

) +

To check for yielding, Eq. 30 is compared to the yield strength, then

𝑛𝑦 =

Note: for a quick conservative check, the sum of alternating stress and the midrange

stress is always greater or equal to the maximum stress therefore, the results will be

conservative.

Therefore,

𝑛𝑦

𝑠𝑦 𝑠𝑦

𝑛𝑦 = 3](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-33-2048.jpg)

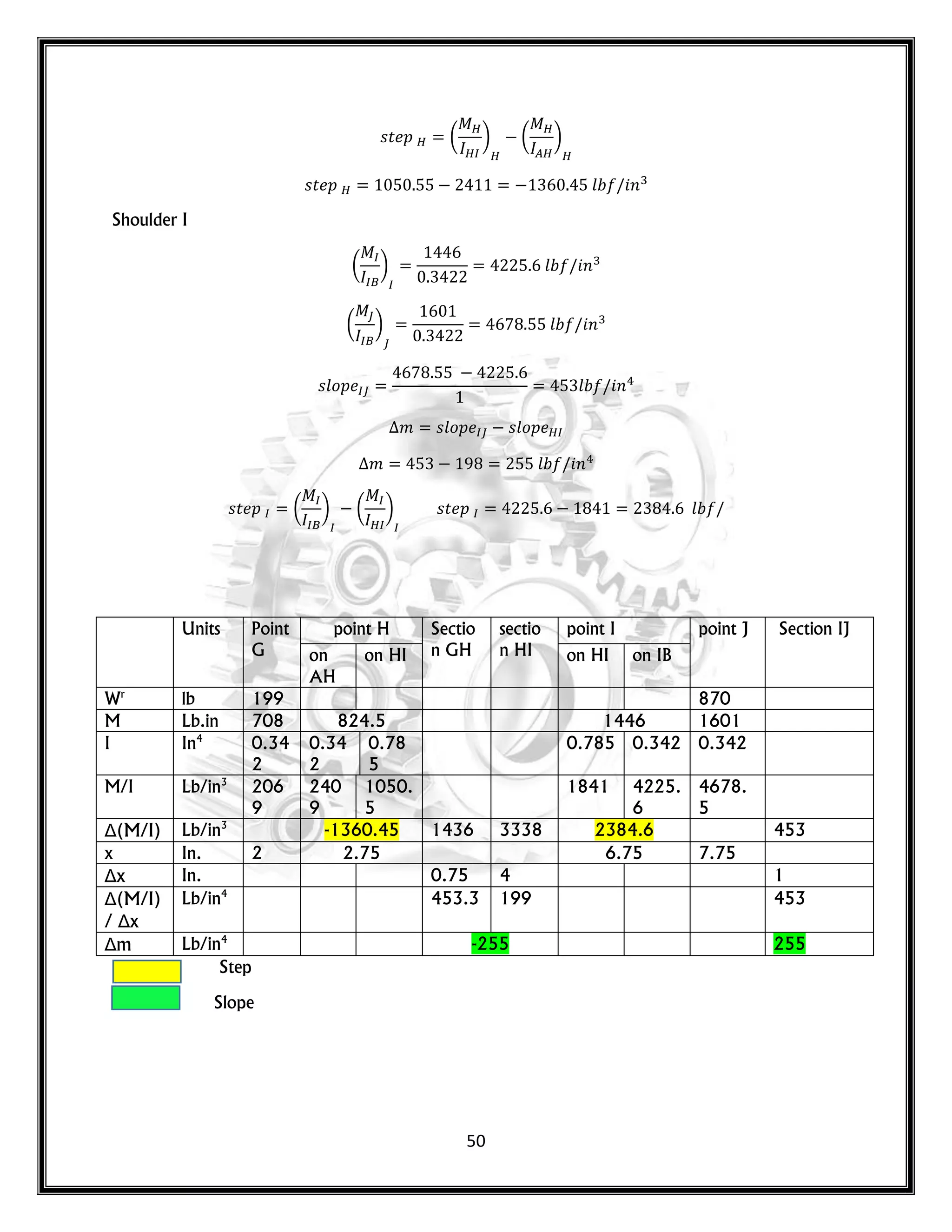

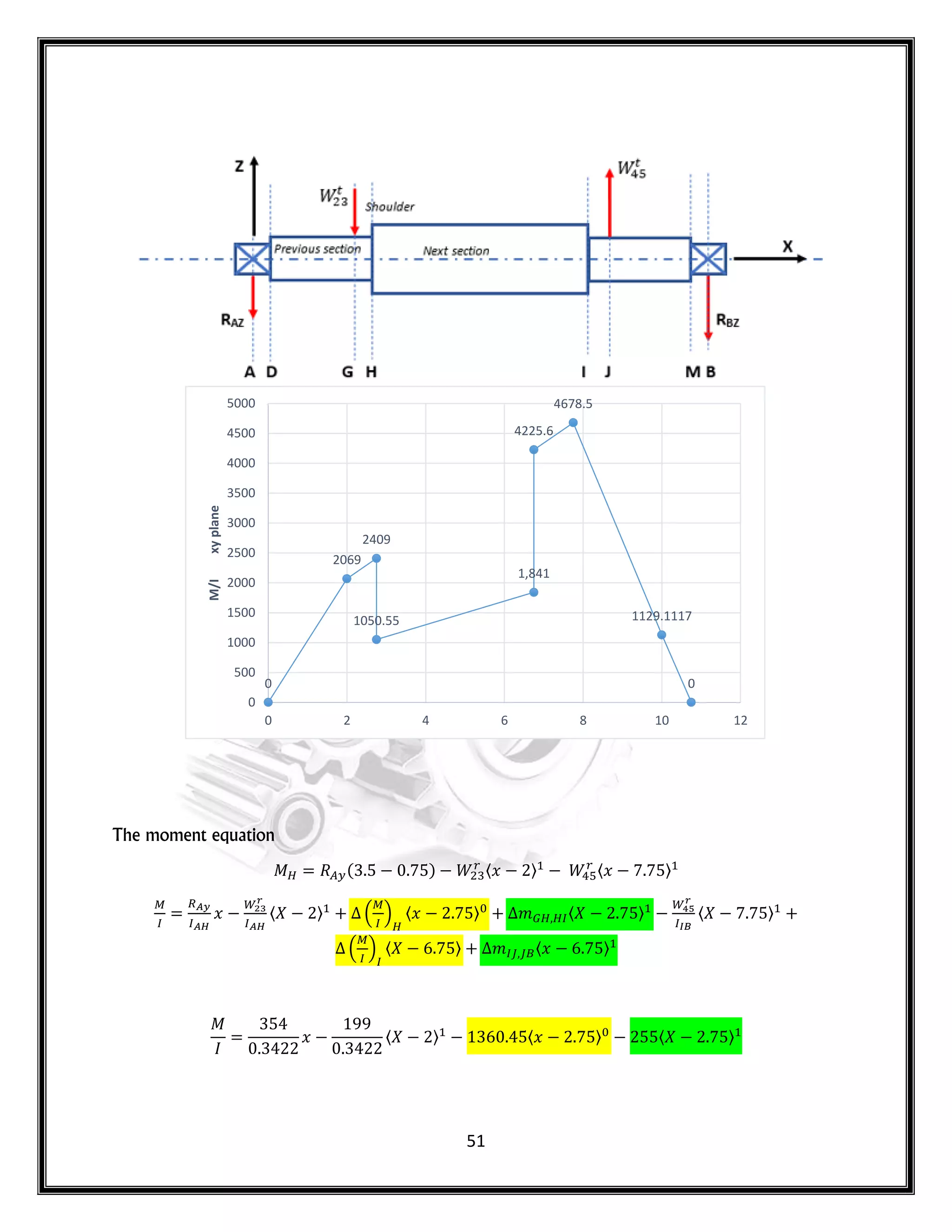

![42

Y P P

Shoulder

X

RA RB

A D G H I J M B

n

Previous sectio

Next section

Figure 4. 11 A stepped shaft subjected to concentrated loads.

Divide the moment equation by the second moment of area (I) of the previous section

of the shaft. The equation becomes.

At the distance (𝑥 ) where the shoulder exists, add a step change in ( ⁄ ) as

follows:

𝑠𝑡 𝑝 . /

𝑠𝑡 𝑝 ( ) ( )

At the distance (𝑥 ) where the shoulder exists, add a ramp change in ( ⁄ ) as

follows:

𝑠𝑙𝑜𝑝 𝑚 [

. /

𝑥

]

𝑚 [

. / . /

𝑥

]

( )

𝑛

( )

𝑛](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-42-2048.jpg)

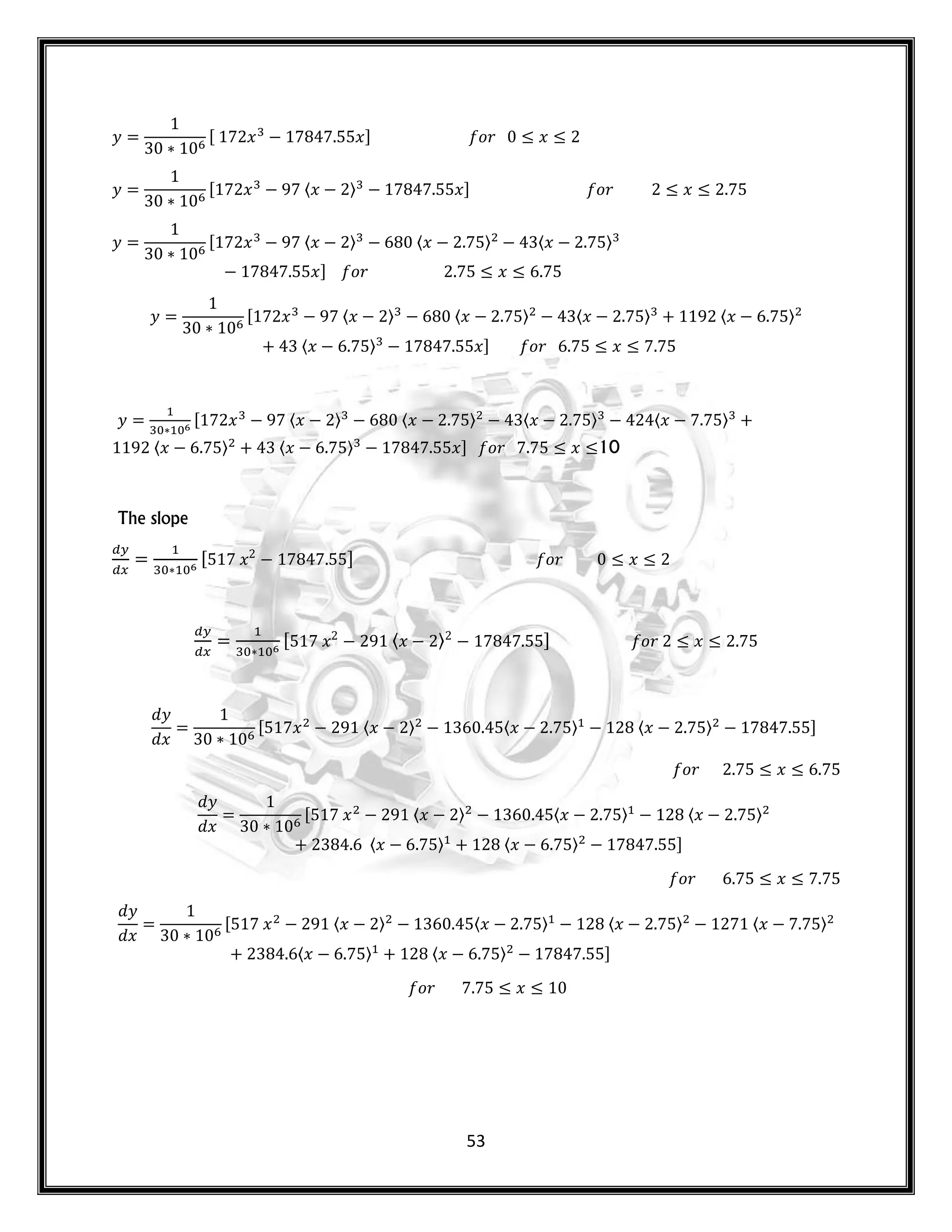

![47

𝑦 , 𝑥 〈𝑥 〉 〈𝑥 〉 〈𝑥 〉 〈𝑥 〉

〈𝑥 〉 𝑥- 𝑜𝑟 𝑥

𝑦 , 𝑥 〈𝑥 〉 〈𝑥 〉 〈𝑥 〉 〈𝑥 〉

〈𝑥 〉 〈𝑥 〉

𝑥- 𝑜𝑟 𝑥

The slope

, 𝑥 - 𝑜𝑟 𝑥

, 𝑥 〈𝑥 〉 - 𝑜𝑟 𝑥

𝑦

𝑥

, 𝑥 〈𝑥 〉 〈𝑥 〉 〈𝑥 〉 -

𝑜𝑟 𝑥

𝑦

𝑥

, 𝑥 〈𝑥 〉 〈𝑥 〉 〈𝑥 〉 〈𝑥 〉

〈𝑥 〉 -

𝑜𝑟 𝑥

𝑦

𝑥

, 𝑥 〈𝑥 〉 〈𝑥 〉 〈𝑥 〉 〈𝑥 〉

〈𝑥 〉 〈𝑥 〉 -

𝑜𝑟 𝑥

x

[in.]

Point Fittings y

[in.]

dy/dx

[deg.]

0 A Left bearing 0 0.0221

2 G Gear 3 - 0.00076 0.0210

2.75 H Shoulder H - 0.00102

6.75 I Shoulder I - 0.00184

7.75 J Gear 4 - 0.00167 0.0203

10 B Right

Bearing

0 0.0671](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-47-2048.jpg)

![48

𝑠𝑡 𝑝 . /

𝑠𝑡 𝑝 ( ) ( )

At the distance (𝑥 ) where the shoulder exists, add a ramp change in ( ⁄ ) as

follows:

𝑠𝑙𝑜𝑝 𝑚 [

. /

𝑥

]

0

-0.00076

-0.00102

-0.00184

-0.00167

0

-0.0025

-0.002

-0.0015

-0.001

-0.0005

0

y

[in.]

x [in.]

Deflection](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-48-2048.jpg)

![49

𝑚 [

. / . /

𝑥

]

( )

𝑛

( )

𝑛

X-Y plane Shoulder H

( ) 𝑙 𝑛

( ) ( )

( ) ( ) 𝑙 𝑛

( ) 𝑙 𝑛

𝑠𝑙𝑜𝑝 𝑙 𝑛

( ) 𝑙 𝑛

( ) 𝑙 𝑛

𝑠𝑙𝑜𝑝 𝑙 𝑛

𝑚 𝑠𝑙𝑜𝑝 𝑠𝑙𝑜𝑝

𝑚 𝑙 𝑛](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-49-2048.jpg)

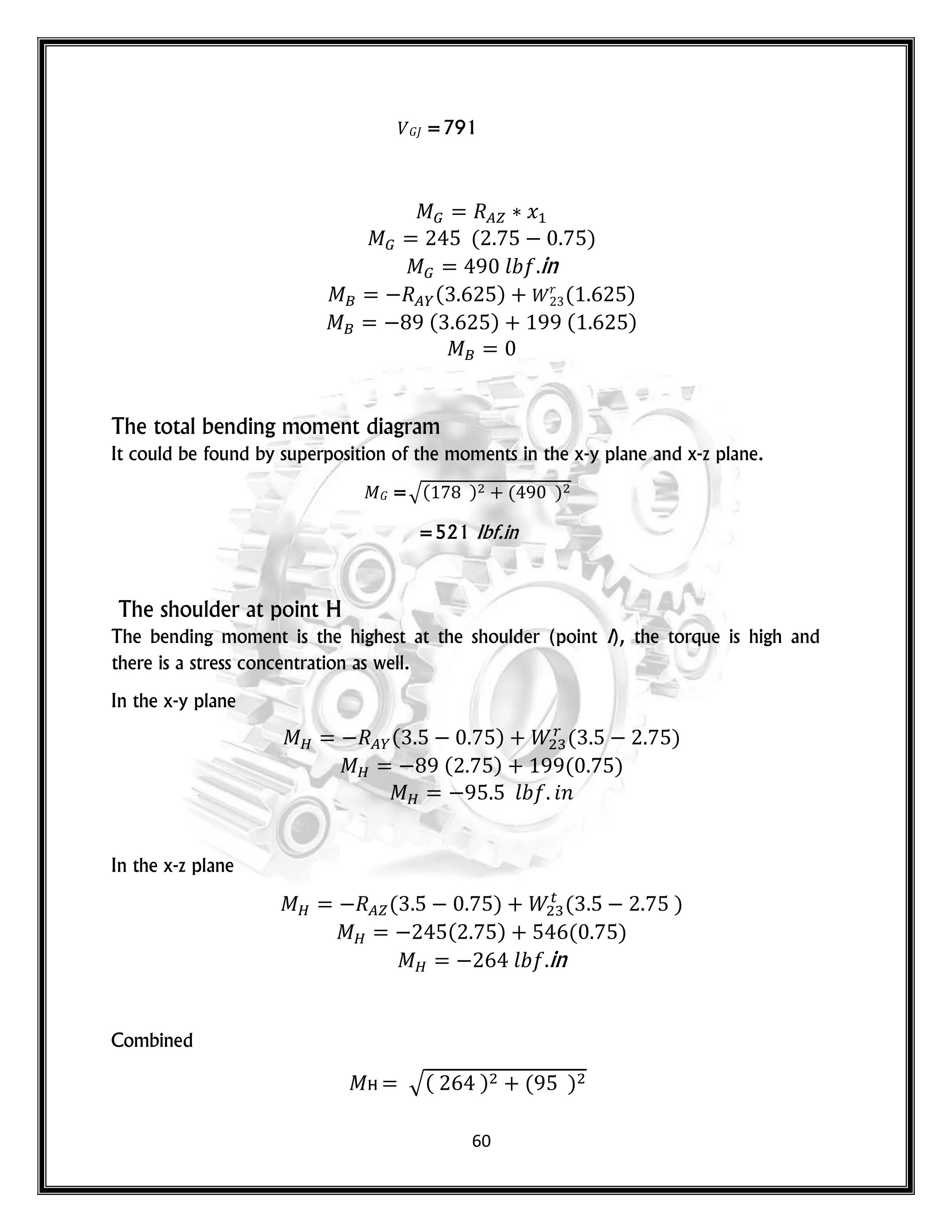

![54

x

[in.]

Point Fittings y

[in.]

dy/dx

[deg.]

0 A Left bearing 0 0.0340

2 G Gear 3 - 0.000114 0.0301

2.75 H Shoulder H - 0.001680

6.75 I Shoulder I - 0.003053

7.75 J Gear 4 - 0.005927 0.00746

10 B Right

Bearing

0 0.00249

0 -0.000114

-0.00168

-0.003053

-0.005927

0

-0.007

-0.006

-0.005

-0.004

-0.003

-0.002

-0.001

0

0.001

y

[in.]

x [in.]

Deflection](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-54-2048.jpg)

![55

The final bearing slope results show

slope

Bearings xz plane

[Deg.]

xy plane

[Deg.]

Total

[Deg.]

Total [rad.]

Left 0.0221 0.0340 0.056 0.000977

Right 0.0671 0.00249 0.068 0.001186](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-55-2048.jpg)

![57

873 873

0

0

100

200

300

400

500

600

700

800

900

1000

y

[in.]

x [in.]

torque diagram (

246 246

301 301

0

0

50

100

150

200

250

300

350

y

[in.]

x [in.]

shear force diagram](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-57-2048.jpg)

![58

0

112.168

490

264

0

0

100

200

300

400

500

600

y

[in.]

x [in.]

moment diagram(x -z)

89 89

-110 -110

0

-150

-100

-50

0

50

100

y

[in.]

x [in.]

shear force diagram(x -y)

0

282.069

490

0

0

100

200

300

400

500

600

y

[in.]

x [in.]

moment diagram(x -y)](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-58-2048.jpg)

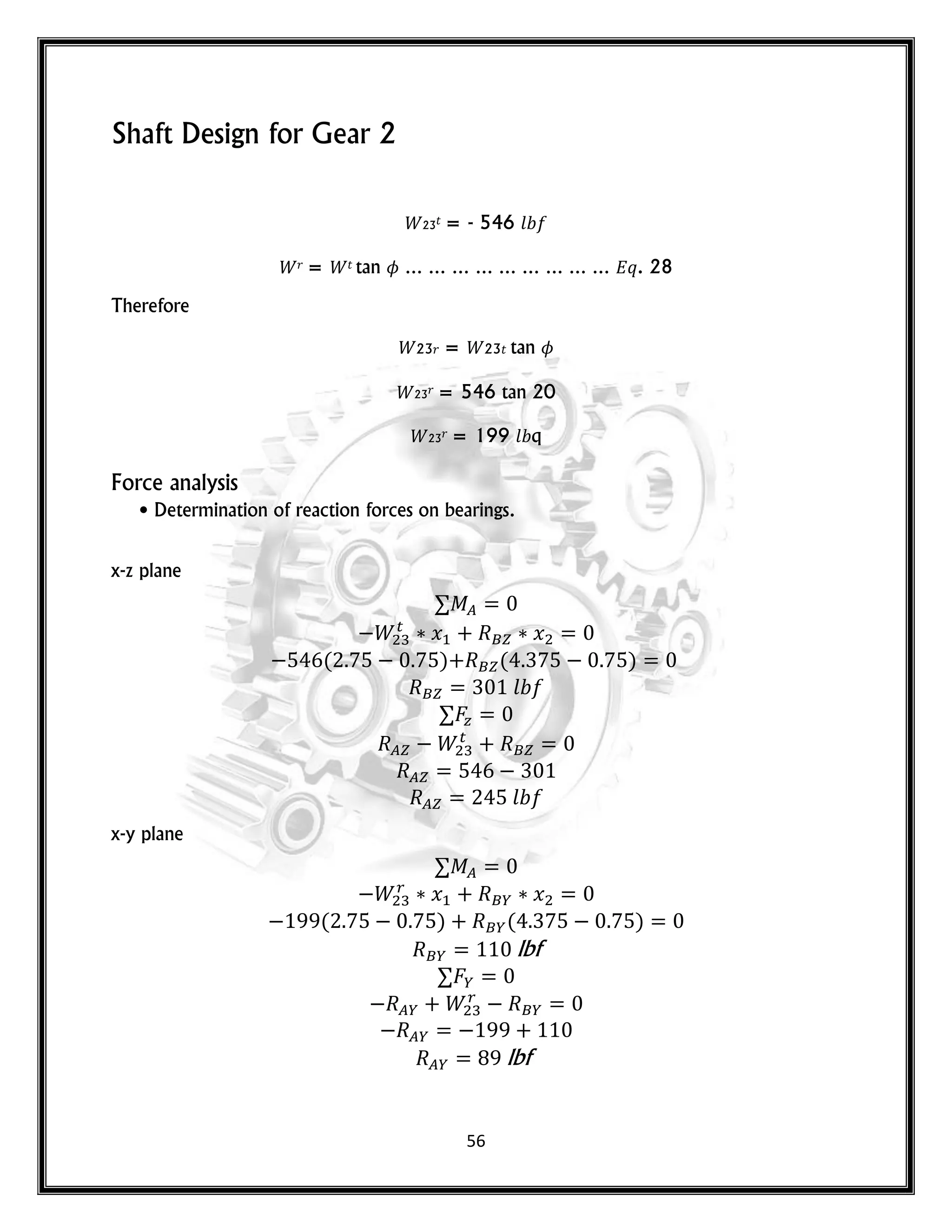

![59

The Shear force and Bending moment diagrams

x-y plane

𝐺 = = 89 𝑙

𝐺 = -

𝐺 = 89 – 199

𝐺 = -110 𝑙

𝑥

( )

𝑙 in

( ) 𝑟

( )

( ) ( )

x-z plane

𝐺 = = -246 𝑙

𝐺 = +

𝐺 = 245 + 546

0

119.366

564.279

515.172

0

0

100

200

300

400

500

600

y

[in.]

x [in.]

moment diagram(x -y)](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-59-2048.jpg)

![65

Check for Yielding

The von Mises maximum stress is :

𝑚 𝑥′= [( 𝑚 + )2 + 3( 𝑚 + )2]1⁄2

*(

𝑘 ( 𝑚 )

) (

𝑘 𝑠( 𝑚 )

) +

𝑛𝑦

𝑠𝑦 𝑠𝑦

= 3.9

The Keyway

From the total bending moment diagram, let the moment at the end of keyway close to

point (I) is

= 390 . 𝑛

Assume that at the bottom of the keyway

= 0.02 ( 𝑠𝑡 𝑛 𝑟 𝑝𝑟𝑜𝑝𝑜𝑟𝑡 𝑜𝑛)

Therefore,

𝑟 =0.02*0.938

𝑟 =0.01876

Using fig. 4.5

𝑡 = 2.49

And using fig. 4.6

𝑞 = 0.58](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-65-2048.jpg)

![72

𝑥 𝑥

( ) ( )

lbf

lbf

16723 16723

0

0

2000

4000

6000

8000

10000

12000

14000

16000

18000

y

[in.]

x [in.]

torque diagram (

1303

395

0

0

200

400

600

800

1000

1200

1400

y

[in.]

x [in.]

shear force diagram](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-72-2048.jpg)

![73

0

2443

0

0

0

500

1000

1500

2000

2500

3000

y

[in.]

x [in.]

moment diagram(x -z)

395 395

-395 -395

0

-500

-400

-300

-200

-100

0

100

200

300

400

500

y

[in.]

x [in.]

shear force diagram(x -y)

0

891

0

0

100

200

300

400

500

600

700

800

900

1000

y

[in.]

x [in.]

moment diagram(x -y)](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-73-2048.jpg)

![74

Figure 4. 3 Freebody diagram, torque, shear force and bending moment diagrams for the shaft.

The Shear force and Bending moment diagrams

x-y plane

𝐺 = = 475 𝑙

𝐺 = -

𝐺 = 475 – 870

𝐺 = -395 𝑙

𝑥

( )

𝑙 in

( ) 𝑟

( )

( ) ( )

0

0

0

2600

0

0

500

1000

1500

2000

2500

3000

y

[in.]

x [in.]

moment diagram(x -y)](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-74-2048.jpg)

![80

Check for Yielding

The von Mises maximum stress is :

𝑚 𝑥′= [( 𝑚 + )2 + 3( 𝑚 + )2]1⁄2

*(

𝑘 ( 𝑚 )

) (

𝑘 𝑠( 𝑚 )

) +

𝑛𝑦

= 1.73

The Keyway

= 1320 . 𝑛

Assume that at the bottom of the keyway

= 0.02 ( 𝑠𝑡 𝑛 𝑟 𝑝𝑟𝑜𝑝𝑜𝑟𝑡 𝑜𝑛)

Therefore,

𝑟 =0.02*1.812](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-80-2048.jpg)

![88

=

Assuming a ball bearing with

= 3

And using eq. 5.2 [

( )( ) ⁄

]

= 1 𝑜𝑟 𝑠𝑡 𝑦 𝑙𝑜 𝑠.

[

( ) ⁄

]

10 = 22086ibf

10 = 22086 0.00444

10 = 98 𝑘

Checking this load with SKF bearing catalogue for ball bearings in the vicinity of 1 in.

diameter, as shown in table. 5.1. It sounds that the load is too high for a deep groove ball

bearing. Repeating the load calculation for a roller bearing with](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-88-2048.jpg)

![89

[

( ) ⁄

]

10 = 17266

10 = 17266 0.00444

10 = 76.66 𝑘

Checking this load with SKF bearing catalogue for roller bearings in the vicinity of 1 in.

diameter, as shown in table. 5.2. The tables show that the following roller bearing matches

the load.

= 83𝑘

𝐷=30𝑚𝑚=1.188 in

𝑂𝐷 = 72 𝑚𝑚 = 2.834 𝑛.

= 27 𝑚𝑚 = 1.063 𝑛.](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-89-2048.jpg)

![90

Left bearing selection

Choosing a ball bearing with

= 3

And using eq. 5.2

[

( )( ) ⁄

]

= 1 𝑜𝑟 𝑠𝑡 𝑦 𝑙𝑜 𝑠.

[

( ) ⁄

]

10 = 4316

10 = 4316 0.00444

10 = 19.16𝑘

Searching table 5.1 that gives the specifications of deep groove ball bearings in the proximity

of 1 in bore and applied load of 19.16kN.

The bearings in this category that matches these requirements is SKF 6305.

The left bearing specifications are

𝐷 = 25𝑚𝑚 = 1 𝑛.

𝑂𝐷 = 62 𝑚𝑚 ≈ 2.5 𝑛.

= 17 𝑚𝑚 = 0.67 𝑛.

= 23.4𝑘 = 5270 𝑙 .

𝑜𝑢𝑙 𝑟 𝑚 𝑡 𝑟 = 1.3~1.4 𝑛.

𝑚 𝑥 𝑚𝑢𝑚 𝑙𝑙 𝑡 𝑟 𝑢𝑠 = 0.08 𝑛.

The right bearing bore is 1.1811 in. which is slightly larger than the estimated one. However,

this has no effect of the design since the diameter of the next step of the shaft is 1.4 in. that

provide the required shoulder for the bearing.](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-90-2048.jpg)

![91

Bearing of Gear 2

Left bearing Selection

𝐺 𝑟 𝑛 𝑟 𝑛 𝑙 = 13 000

High counter shaft speed =1992 rpm.

𝑠𝑡 𝑚 𝑡 𝑜𝑟 𝑠 𝑧 = 0.750 𝑛.

𝑠𝑡 𝑚 𝑡 𝑟 𝑛 𝑤 𝑡 = 1 𝑛.

𝑙 𝑙 𝑡𝑦 = 99 %

𝑧 = 245 𝑦 = 89 = 260 𝑙

=

Assuming a ball bearing with

= 3

[

( ) ⁄

]

10 = 5491.946

10 = 4988 0.00444

10 = 22.14 𝑘

At Table 5.1 ( C= 26 kN)](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-91-2048.jpg)

![92

ID = 25mm

OD = 62mm

W = 17mm

Right bearing Selection

B𝑧 =301 i B𝑦 = 110 B= 320 𝑙

Assuming a roller bearing with

=

=10/3

[

( ) ⁄

]

10 = 4569 𝑙

10 = 4569 0.00444

10 = 20.28 𝑘](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-92-2048.jpg)

![94

[

( ) ⁄

]

10 = 6975

10 = 6975 0.00444

10 = 31 𝑘

At Table 5.2 ( C= 44.6 kN)

ID = 45mm

OD =75 mm

W = 16mm

Right bearing Selection

B𝑧 = 1086 B𝑦 = 395 𝑙 B = 1155 𝑙

Assuming a roller bearing with

= 10/3

[

( ) ⁄

]

10 = 6798 𝑙

10 = 6798 0.00444

10 = 30.18 𝑘

At Table 5.2 ( C = 44.6 kN)

ID = 45mm

OD = 75mm

W = 16mm](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-94-2048.jpg)

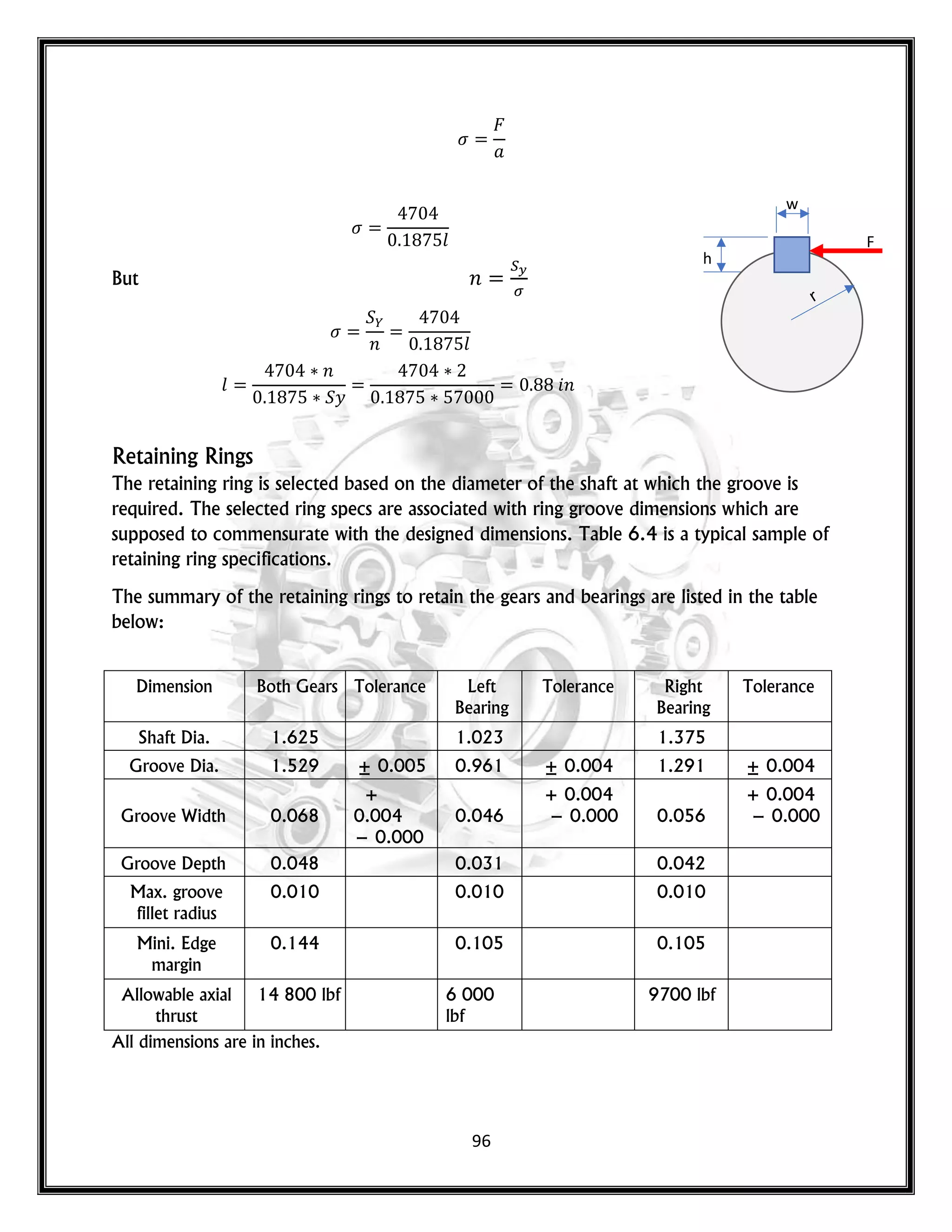

![95

Chapter 6

Key and Keyway Design

For Gear4 & Gear 3.

From the previous data

Bore [in.] Hub length [in.] Torque lbf.in. Safety factor

Gear 3 1.625 1.5

3822 2

Gear 4 1.625 2.0

Using table 6.3 for a square key

Shaft diameter w h Keyway depth

1.625 1 5/8 3/8 3/8 3/16

Choosing key material of 1020 CD steel with 𝑺𝒚 = 𝟓𝟕 𝒌𝒑𝒔𝒊.

The lateral force on the key at the surface of the shaft is:

=

The area prone to bearing stress is

𝑙 𝑙

The bearing stress is](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-95-2048.jpg)

![97

For Gear 2

From the previous data

Bore [in.] Hub length [in.] Torque lbf.in. Safety factor

Gear 2 0.938 1.5 873 2

Using table 6.3 for a square key

Shaft diameter w h Keyway depth

0.938 7.5/8 1/4 1/4 1/8

Choosing key material of 1020 CD steel with 𝑺𝒚 = 𝟓𝟕 𝒌𝒑𝒔𝒊.

The lateral force on the key at the surface of the shaft is:

=

The area prone to bearing stress is

𝑙 𝑙

The bearing stress is

𝑙

But 𝑛

𝑛 𝑙

𝑙

𝑛

𝑦

𝑙 𝑛](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-97-2048.jpg)

![98

For Gear 5

From the previous data

Bore [in.] Hub length [in.] Torque lbf.in. Safety factor

Gear 2 1.812 2 16723 2

Using table 6.3 for a square key

Shaft diameter w h Keyway depth

1.812 1 13/16 1/2 1/2 1/4

Choosing key material of 1045 CD steel with 𝑺𝒚 = 7𝟕 𝒌𝒑𝒔𝒊.

The lateral force on the key at the surface of the shaft is:

=

The area prone to bearing stress is

𝑙 𝑙

The bearing stress is

𝑙

But 𝑛

𝑛

𝑙

𝑛

𝑦

𝑛](https://image.slidesharecdn.com/machinedesigngearboxdesignmahamadjawhar-220425215917/75/machine-design-gear-box-design-mahamad-jawhar-pdf-98-2048.jpg)