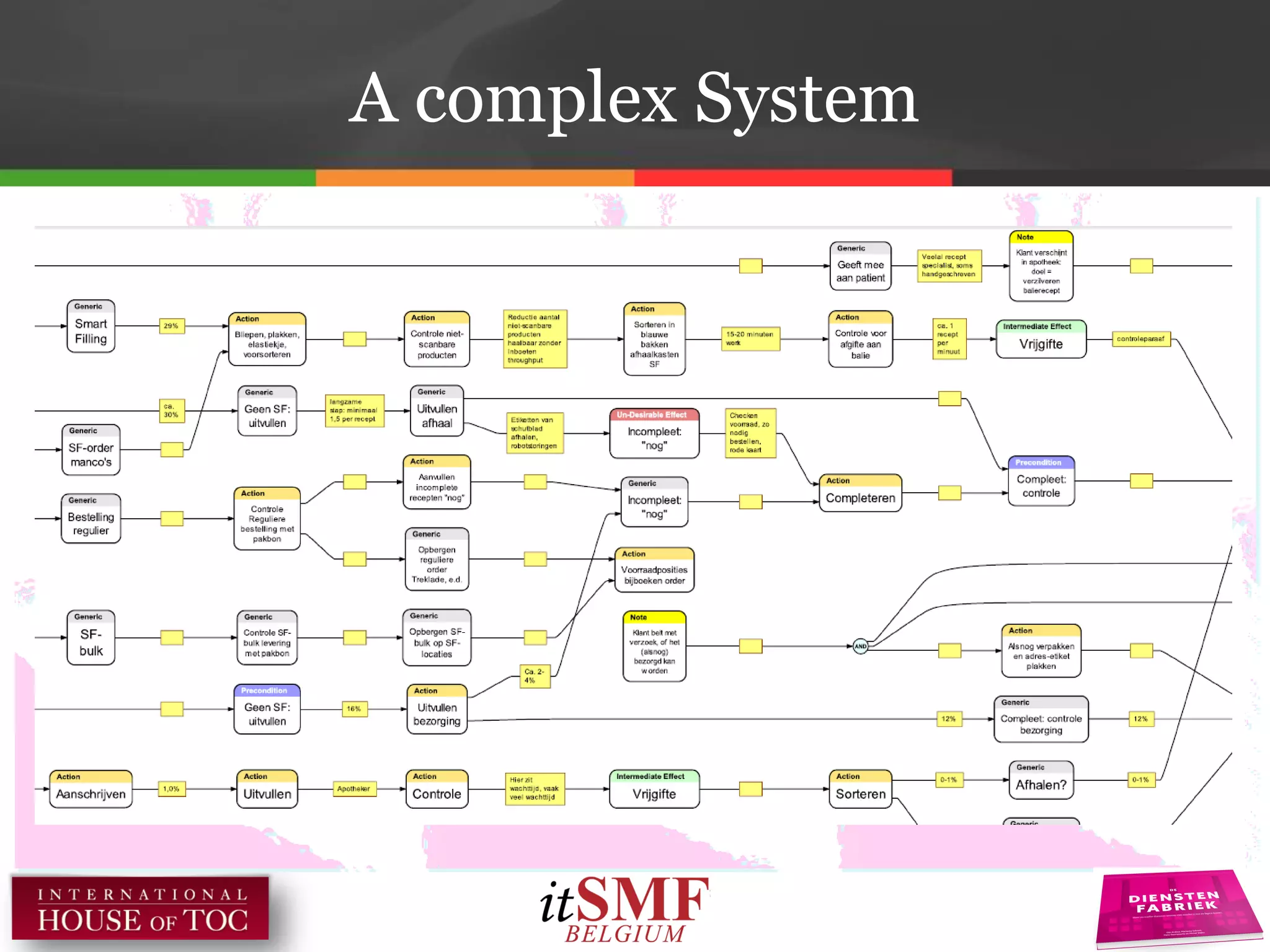

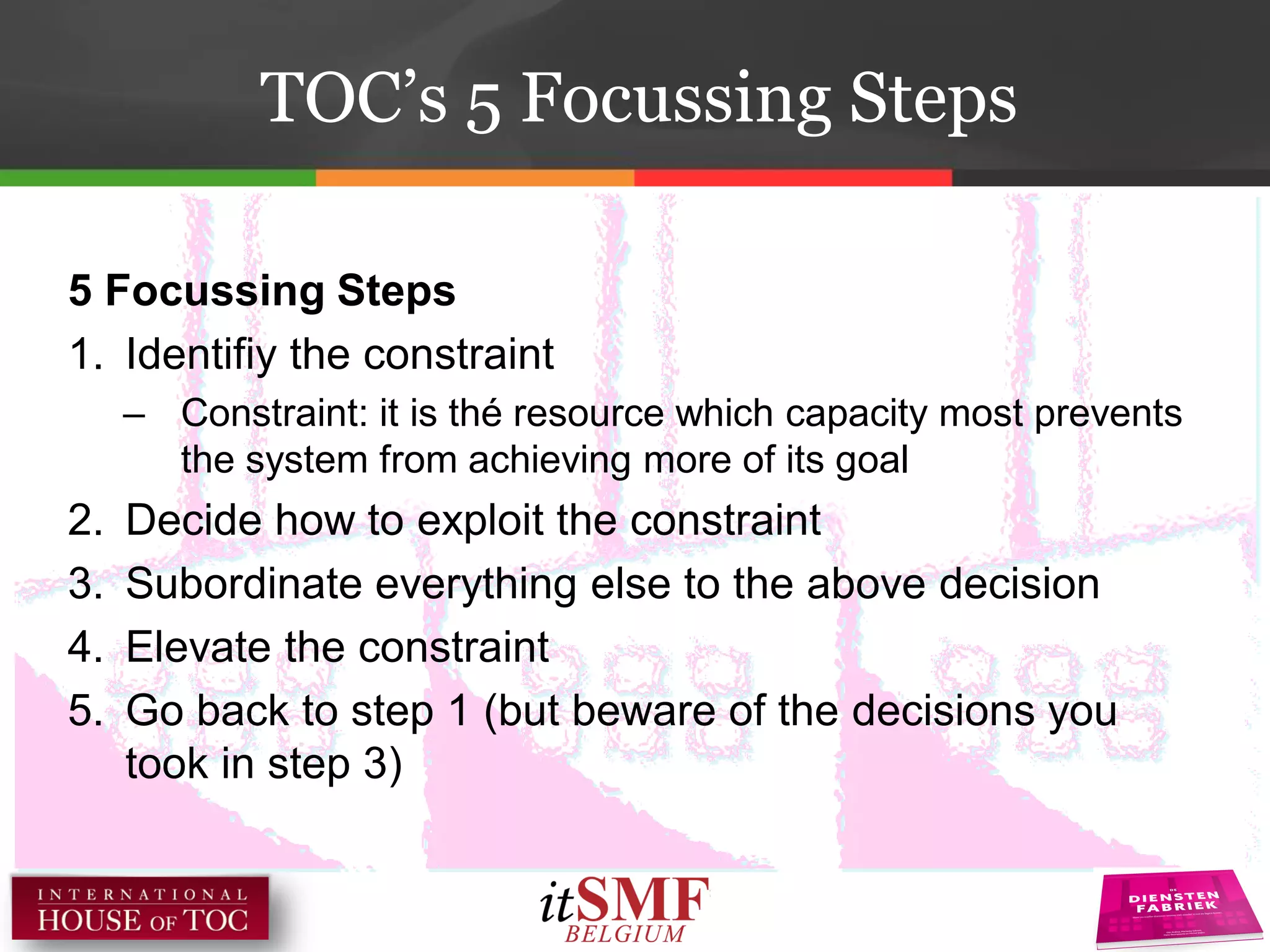

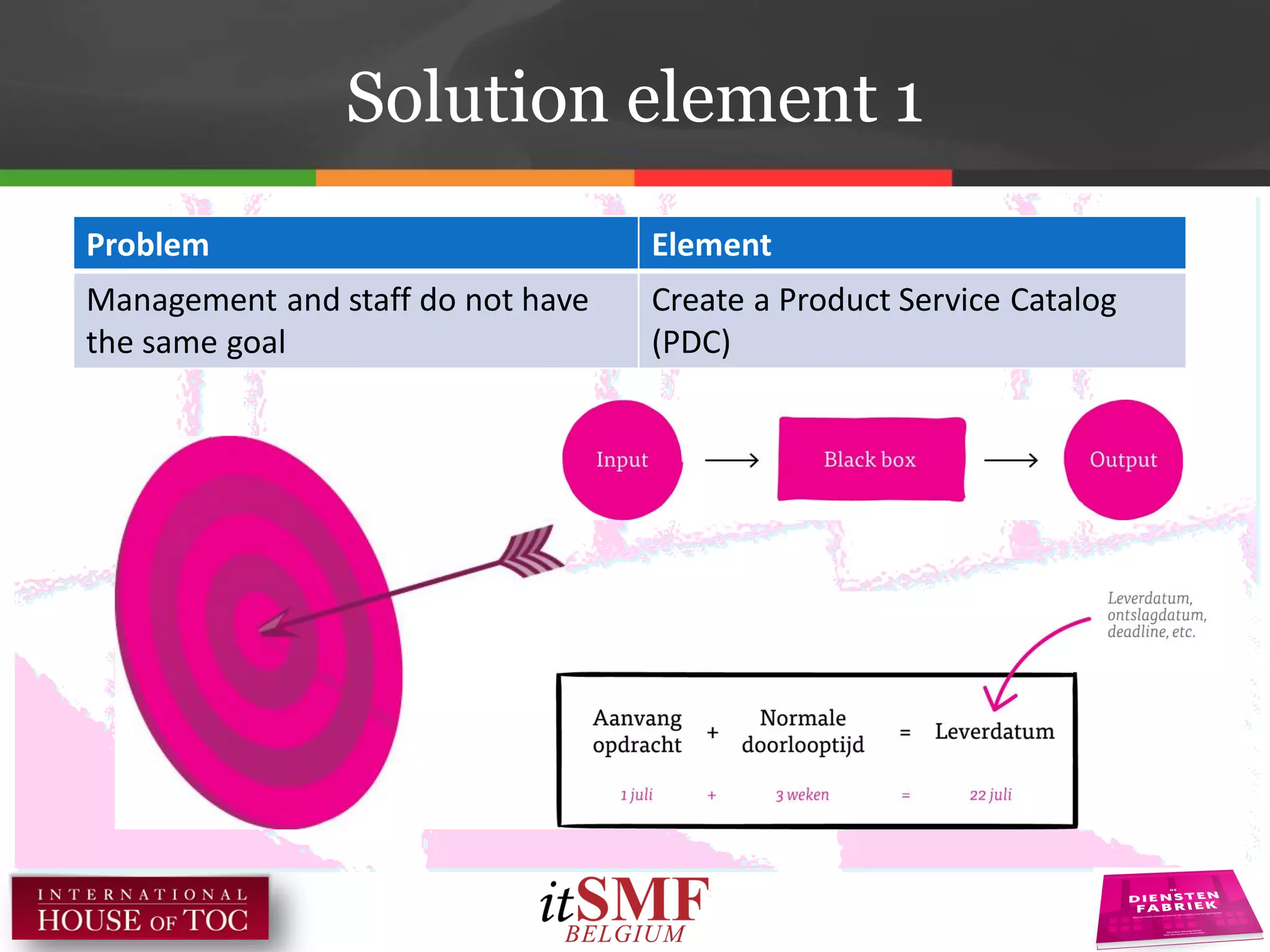

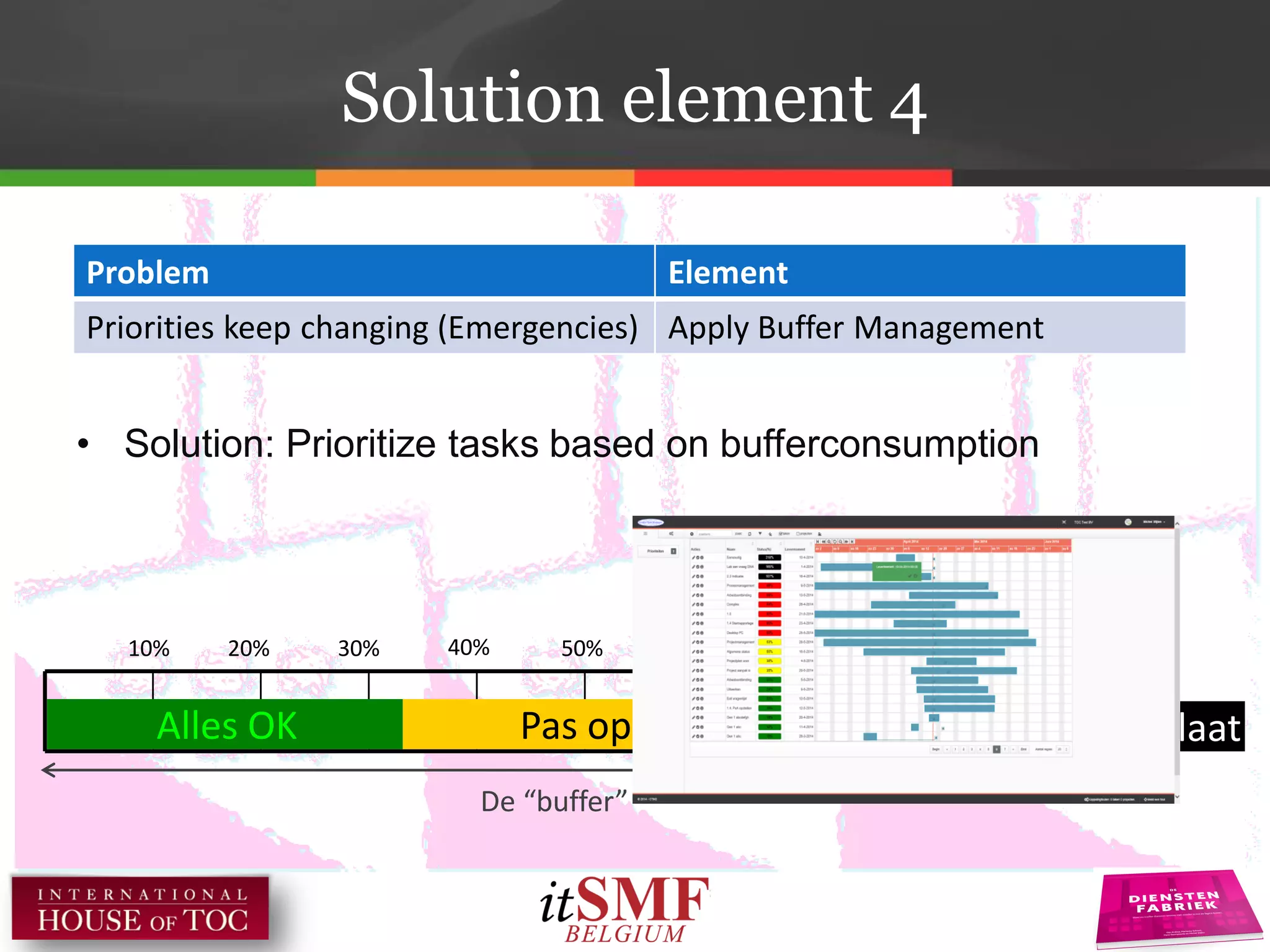

The document introduces the Theory of Constraints (TOC), which was developed by Eliyahu Goldratt. TOC defines that only a few factors govern the overall performance of a complex system. It explains inherent simplicity using examples of organizations and production systems. Running simulations of production systems, it is shown that dependencies and variability determine flow, work-in-progress determines lead time, and following TOC's five focusing steps leads to ongoing improvement. The five steps are identified as: 1) identify the constraint, 2) exploit the constraint, 3) subordinate everything else to the above decisions, 4) elevate the constraint, and 5) return to step 1. Common problems in service organizations are discussed and mapped to speculated causes