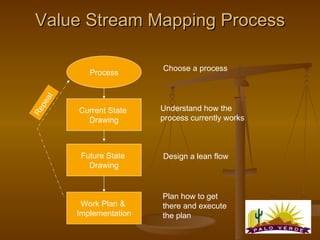

Value stream mapping (VSM) is a visual tool used to analyze the flow of materials and information required to deliver a product or service. It maps out the current process and identifies waste and defects. The goal of VSM is to design a future state map that improves the process by eliminating waste and reducing lead times and inventory levels. An implementation plan is then created to transition from the current to the future state through specific tasks assigned to individuals with milestones and reviews.