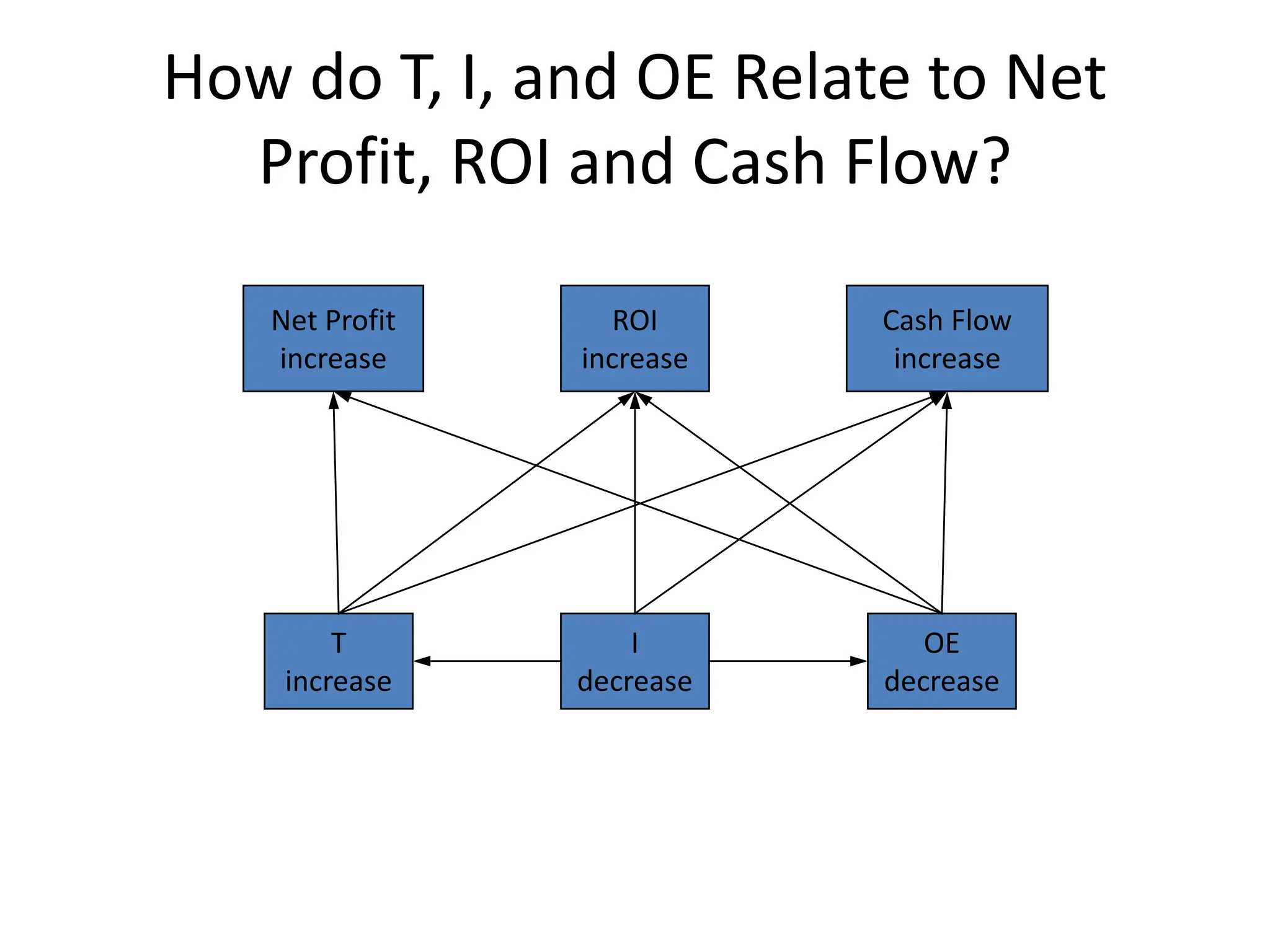

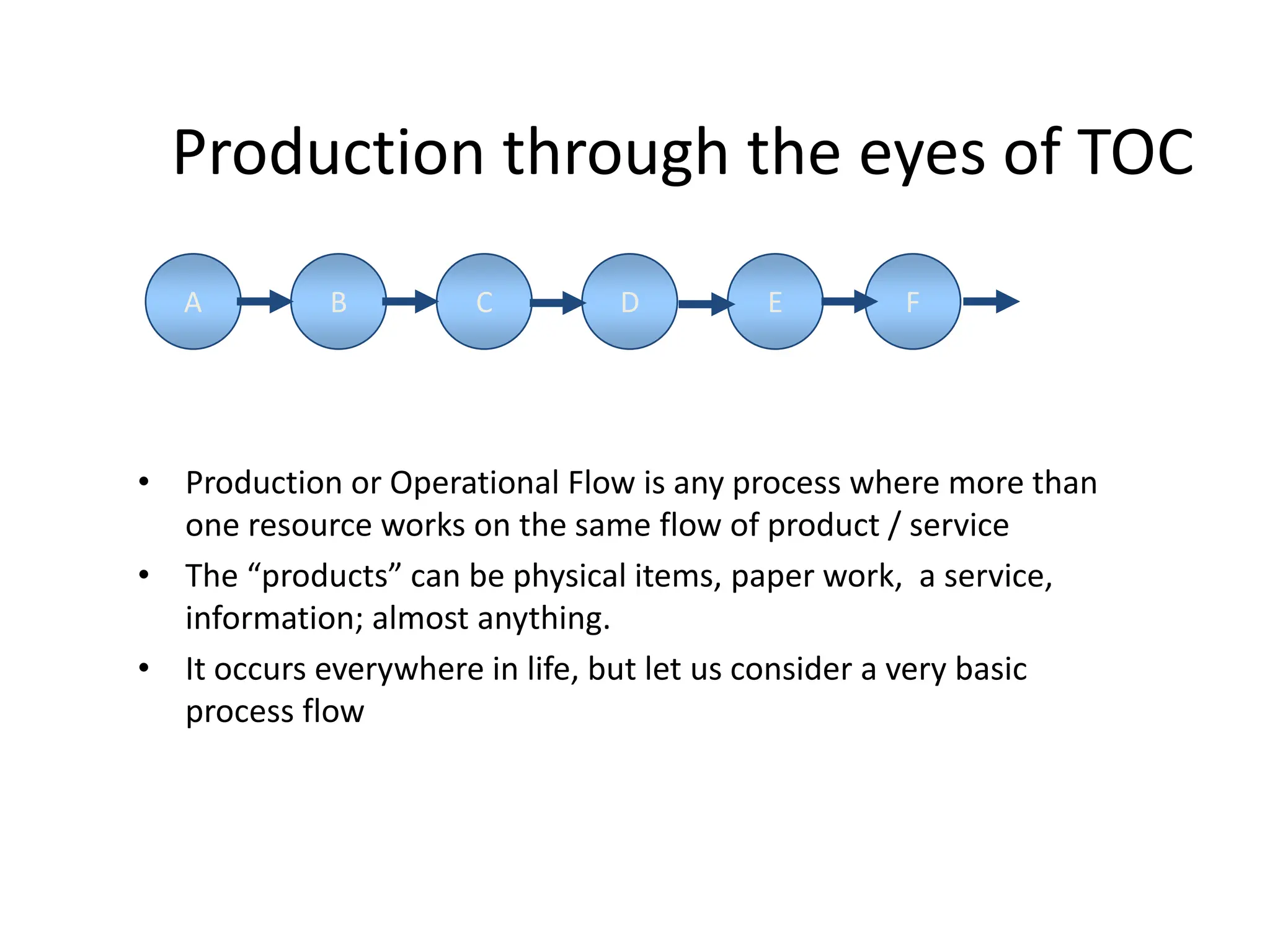

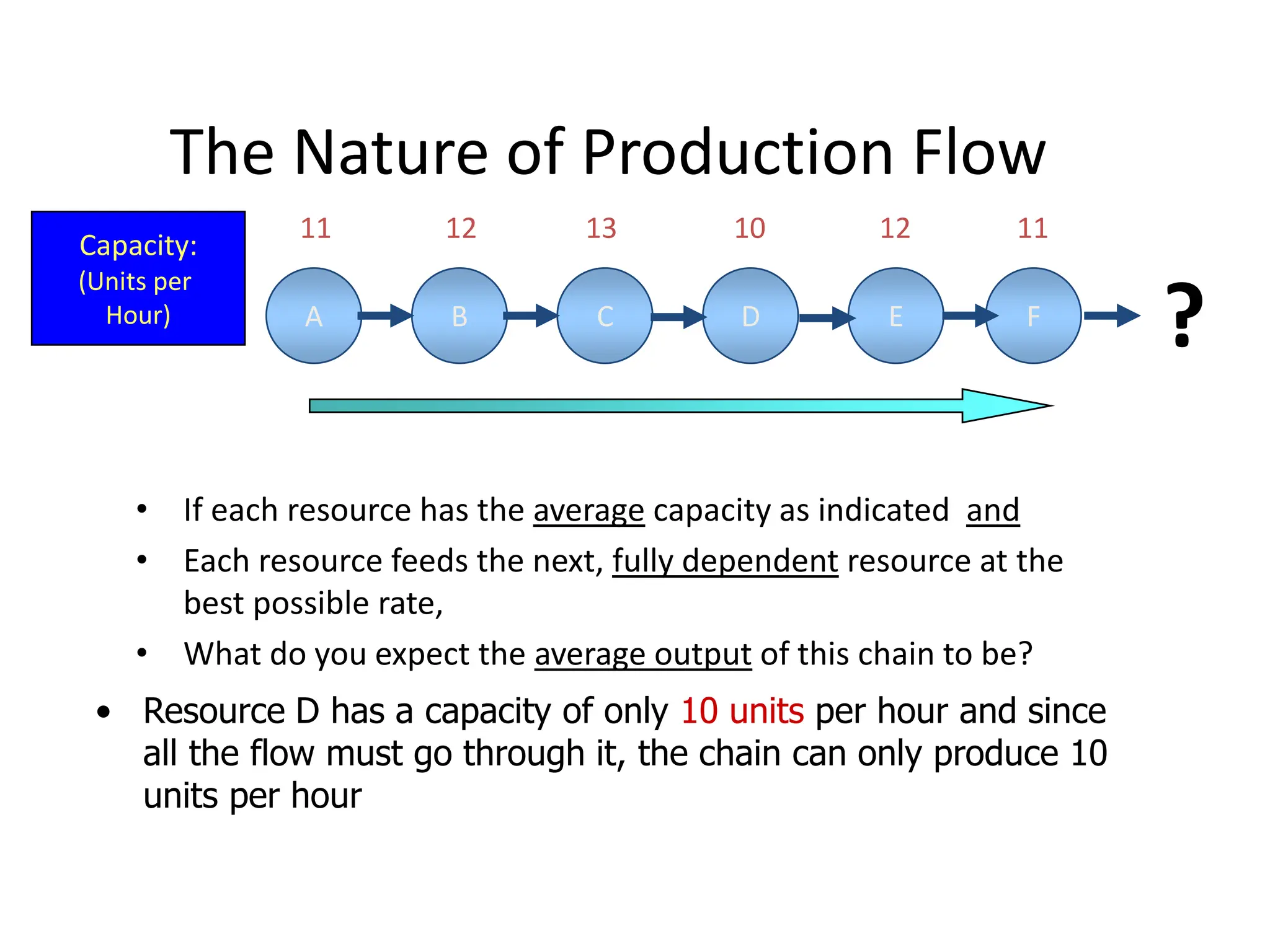

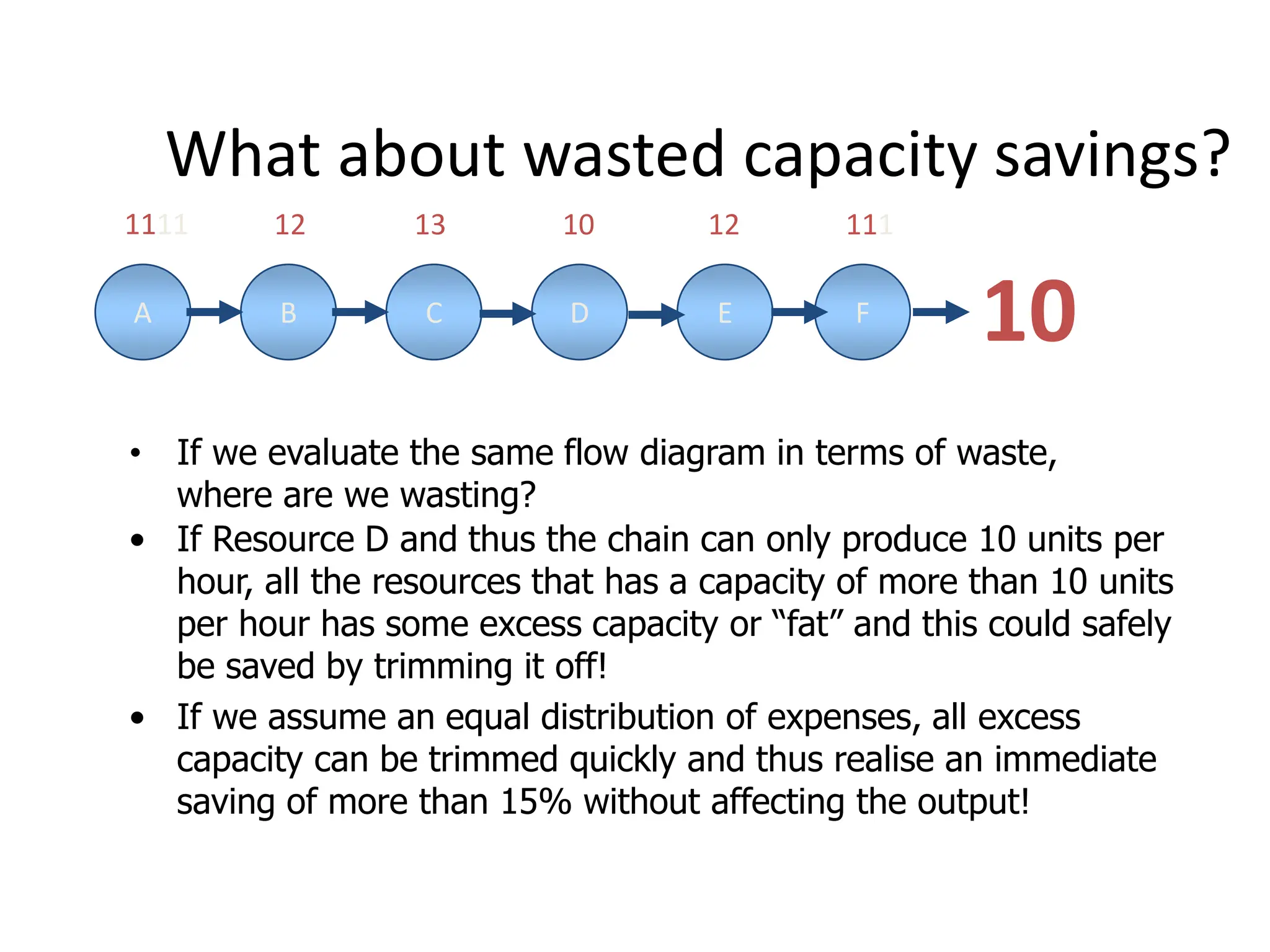

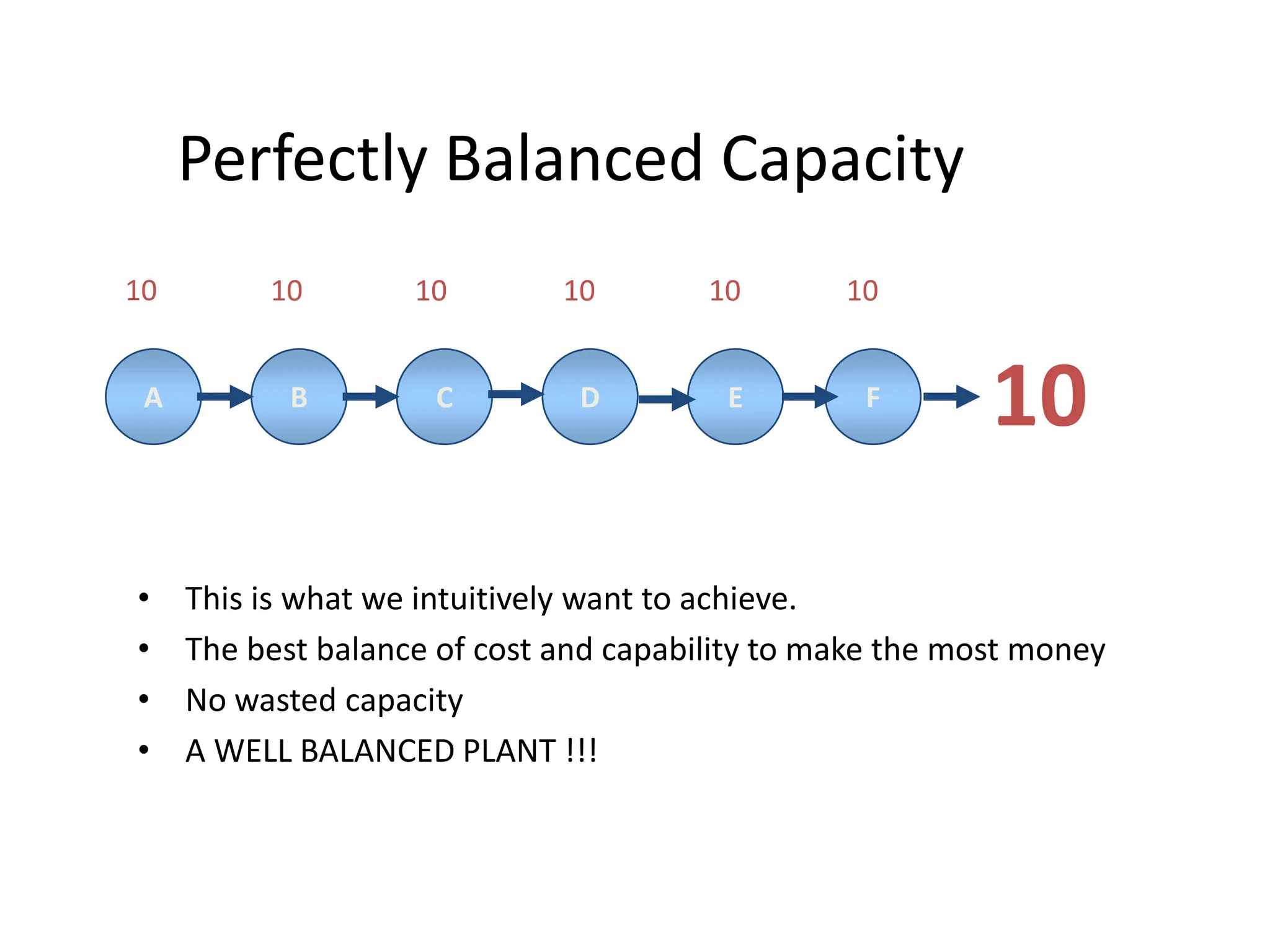

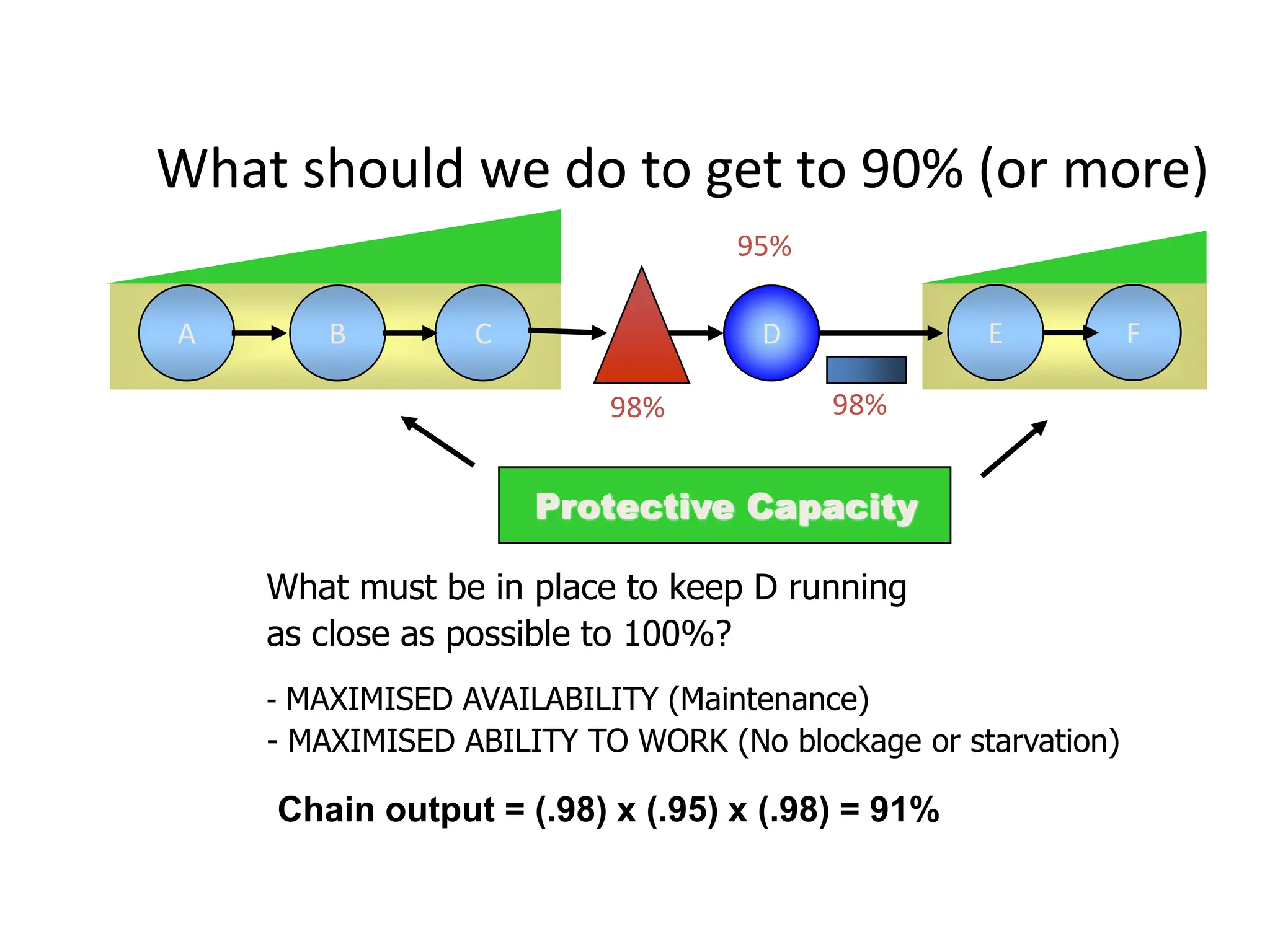

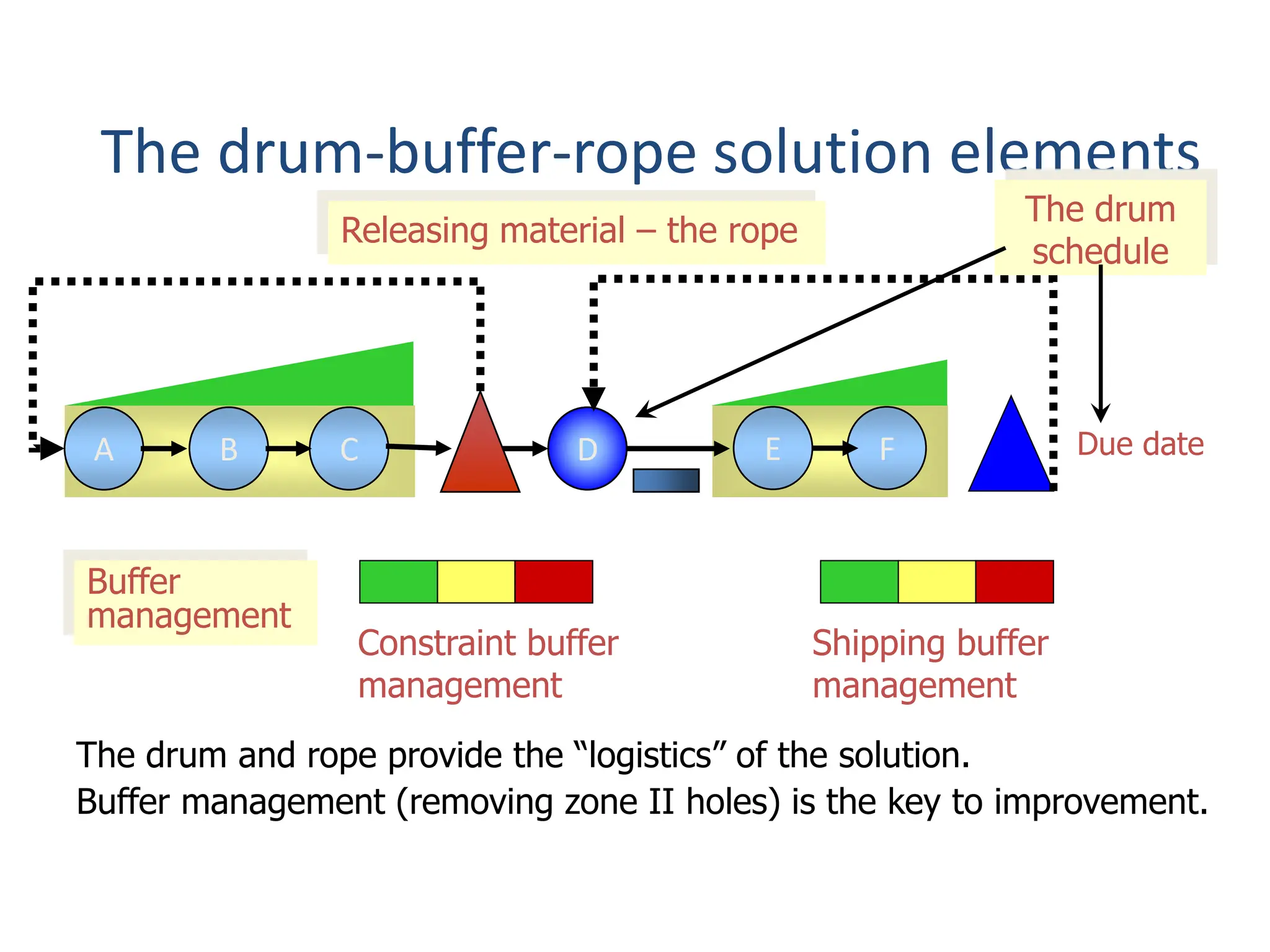

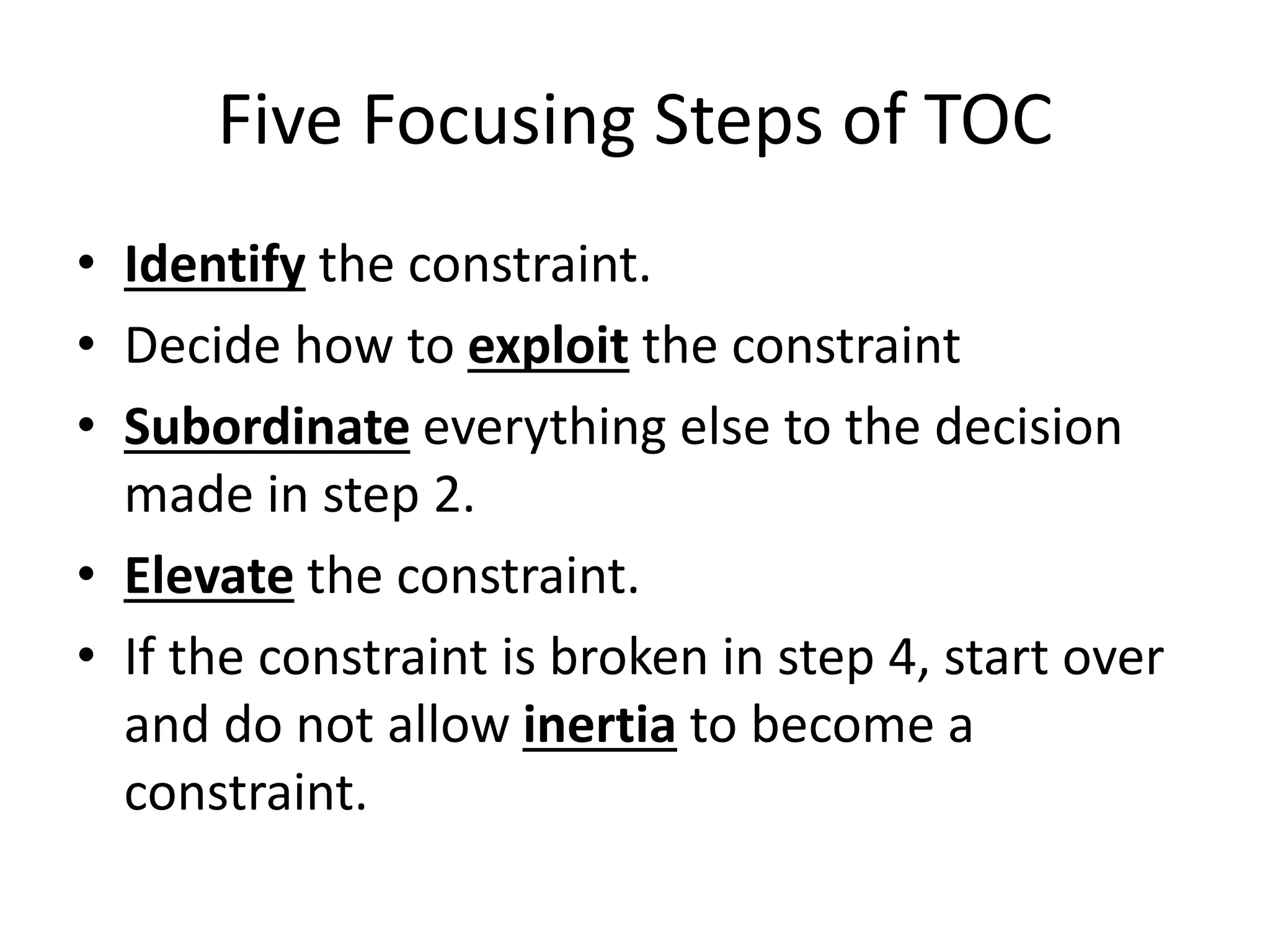

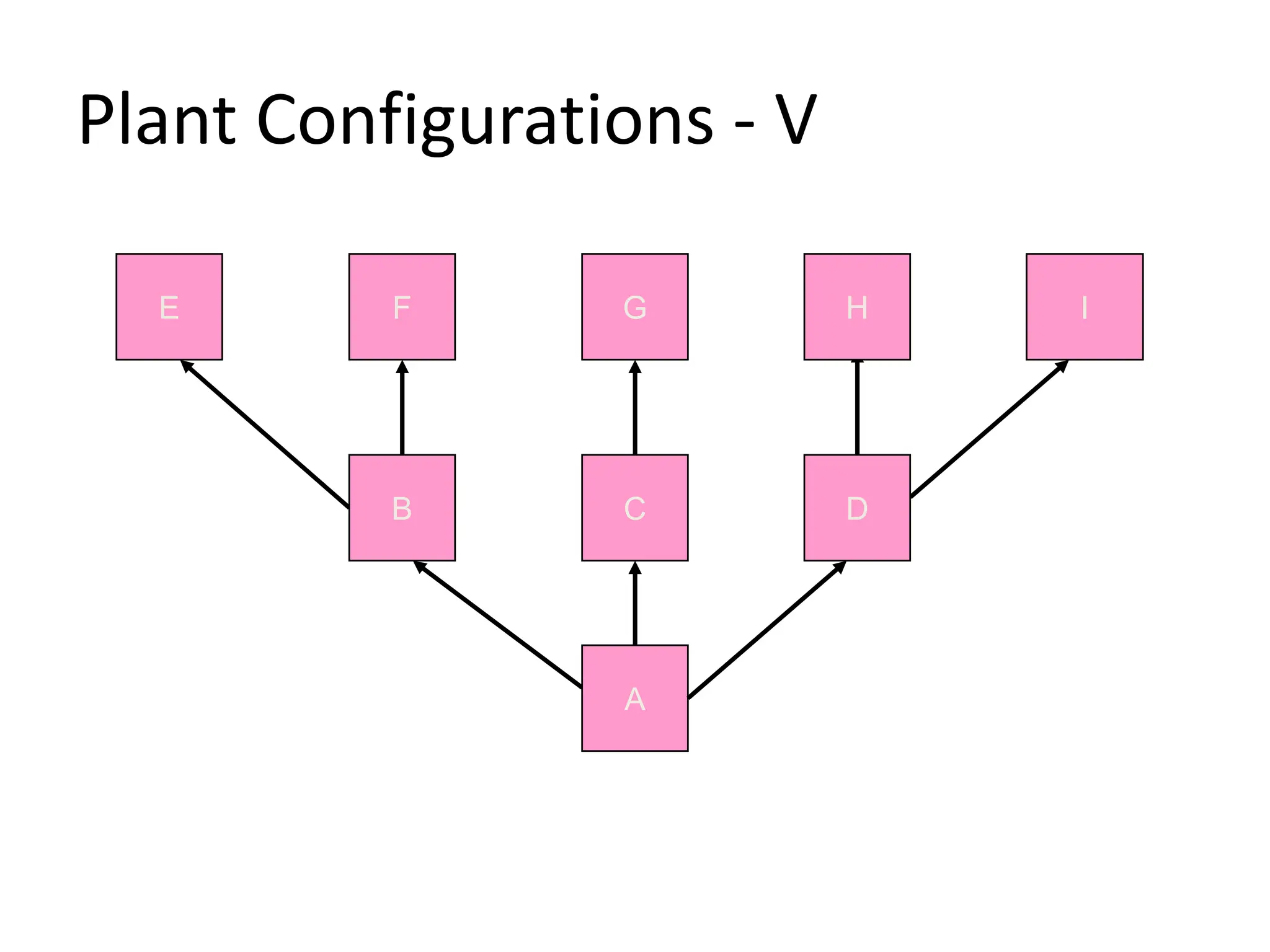

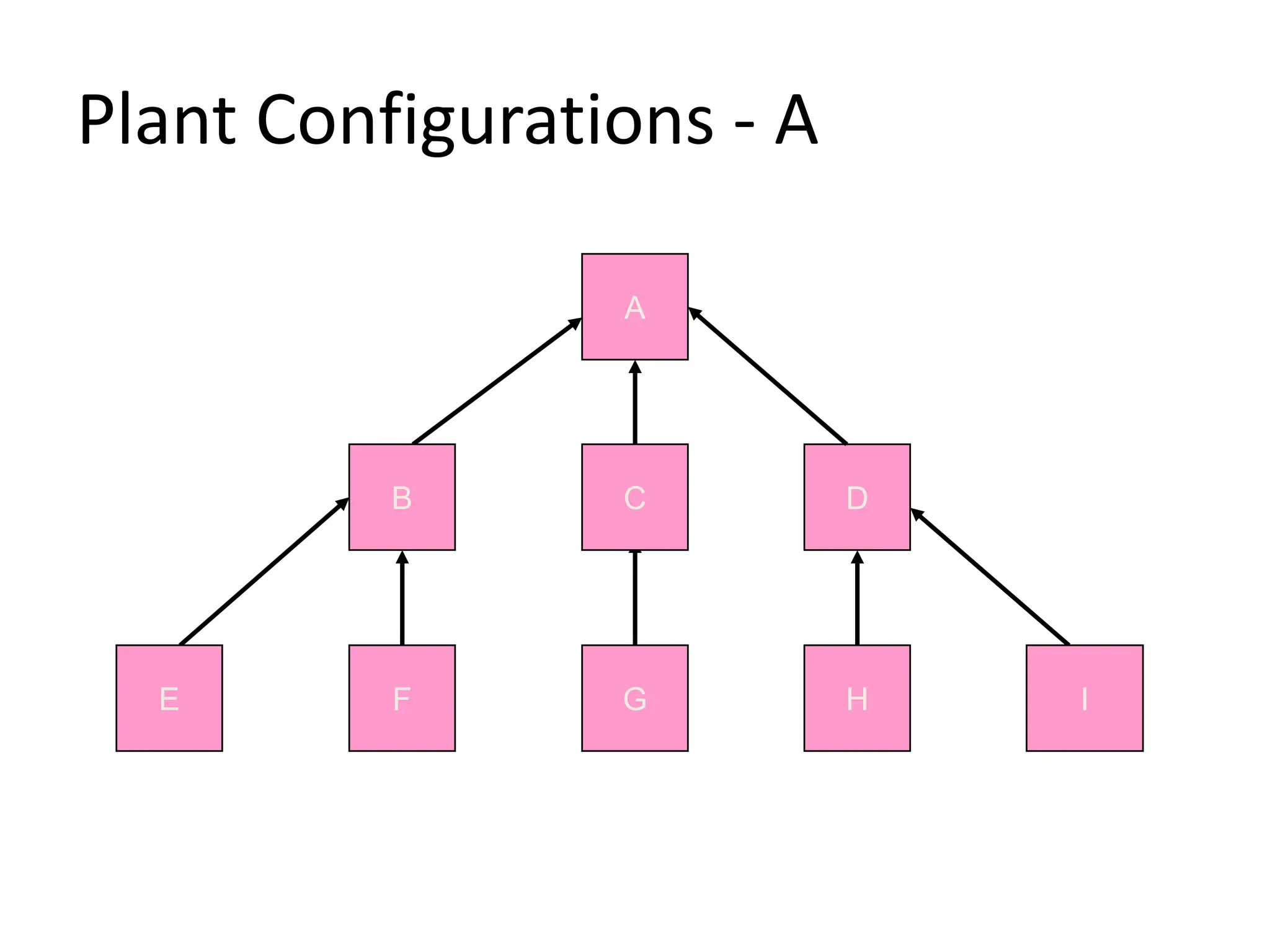

The Theory of Constraints (TOC), developed by Dr. Eliyahu Goldratt, is a comprehensive approach to improving organizational performance by identifying and addressing constraints within a system. TOC emphasizes that a system cannot be optimized by merely improving individual components but rather requires a holistic view that identifies the single most significant constraint limiting overall performance. The document outlines TOC's principles, applications across various fields, its practical methodologies including throughput accounting, and the structured TOC thinking process for problem-solving.