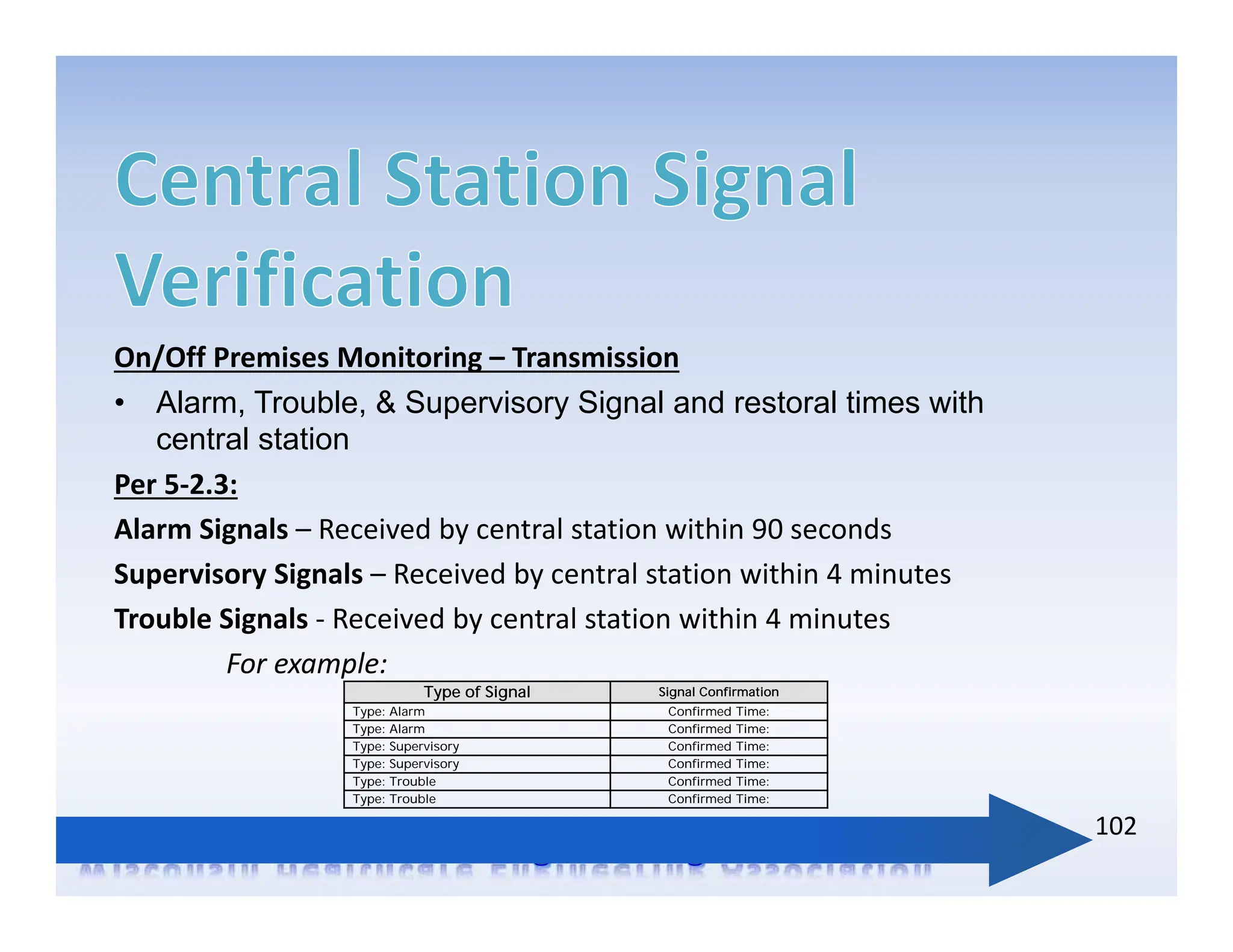

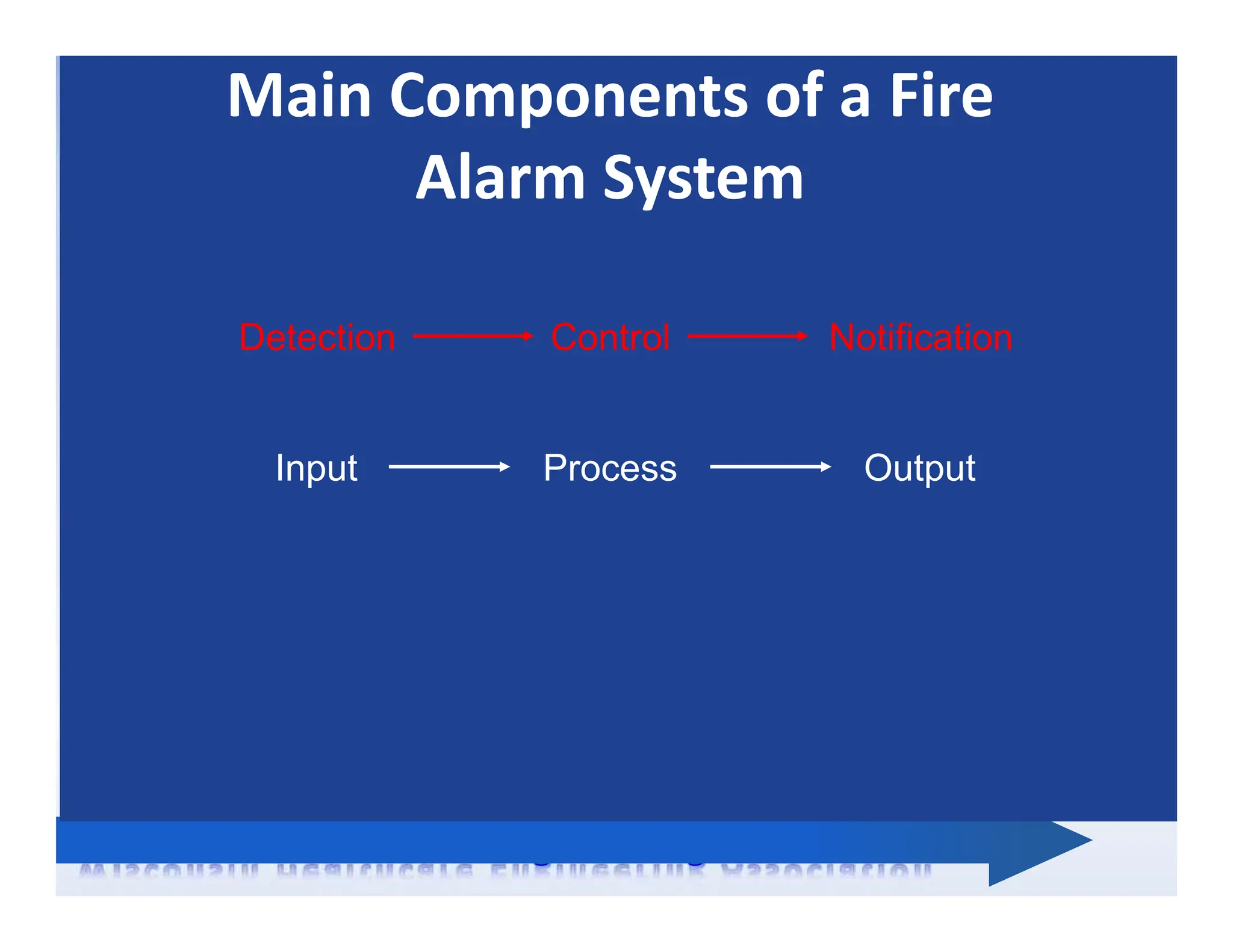

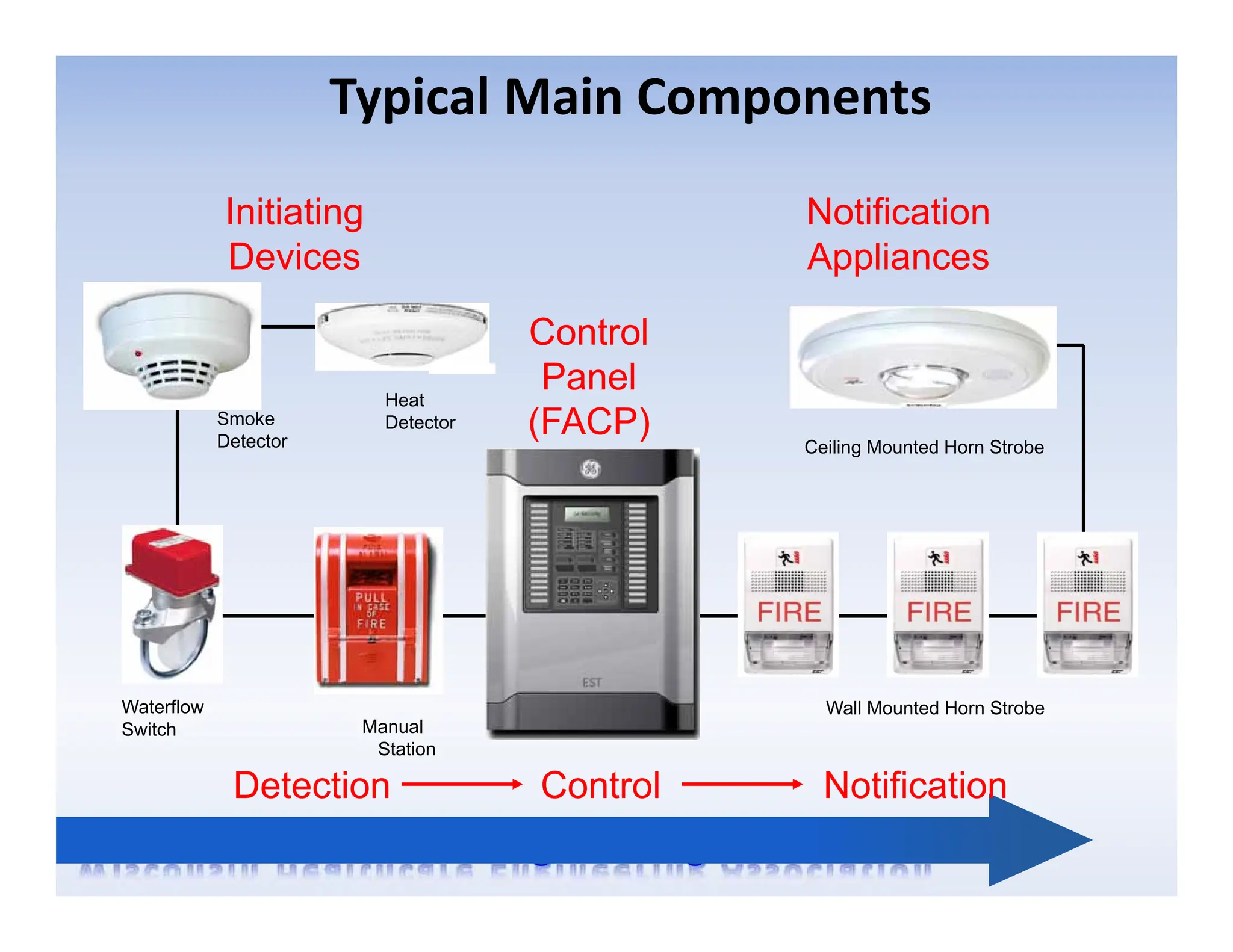

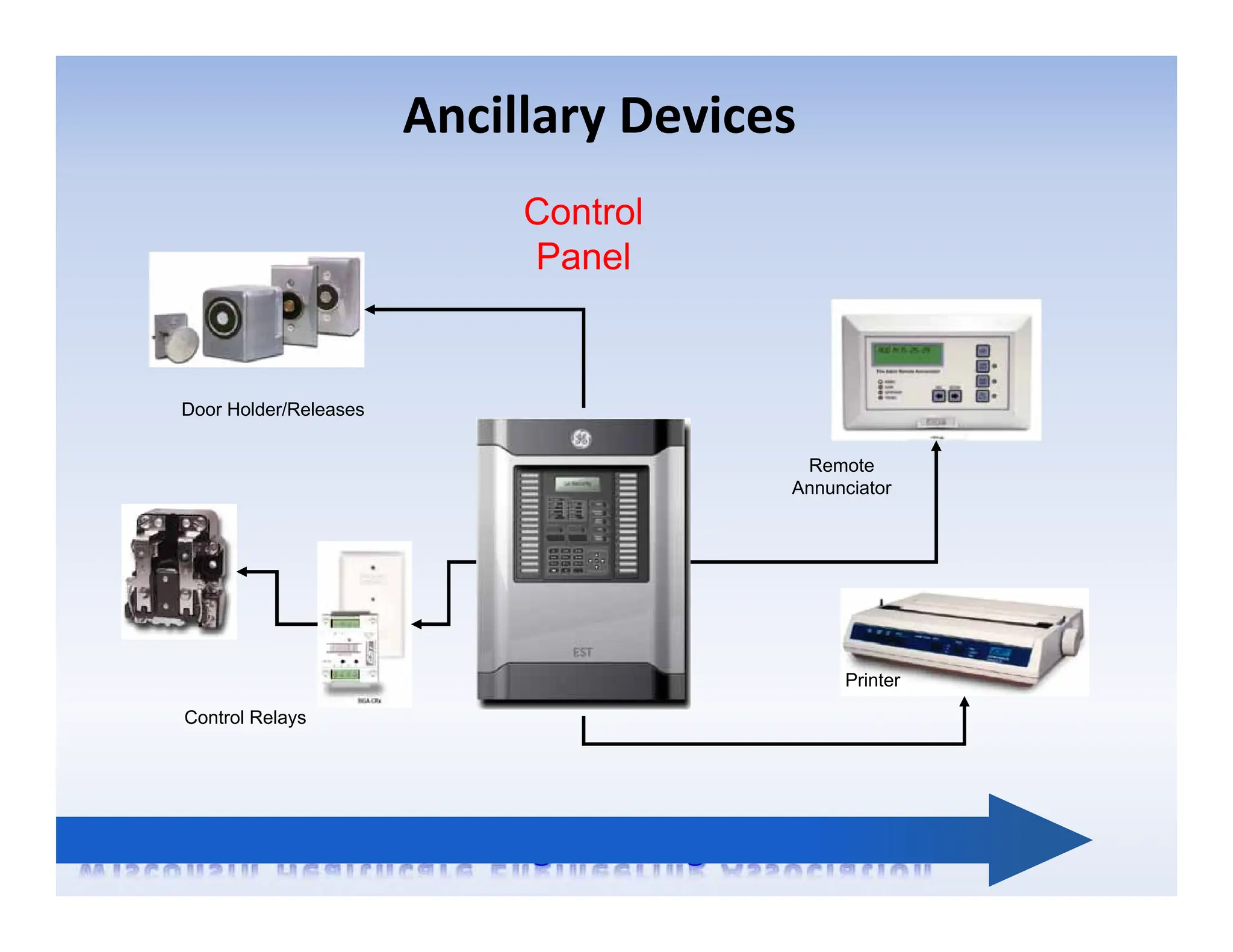

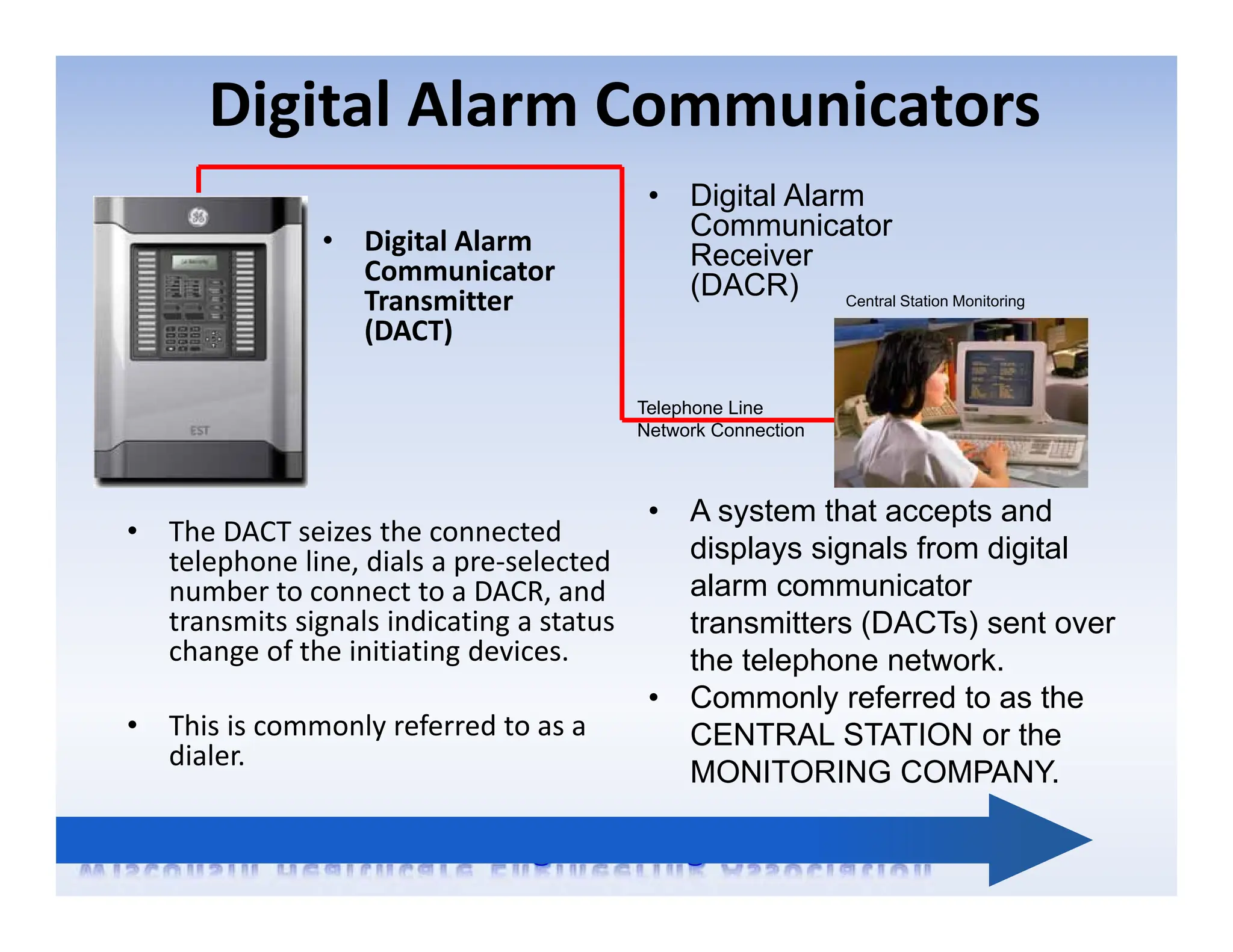

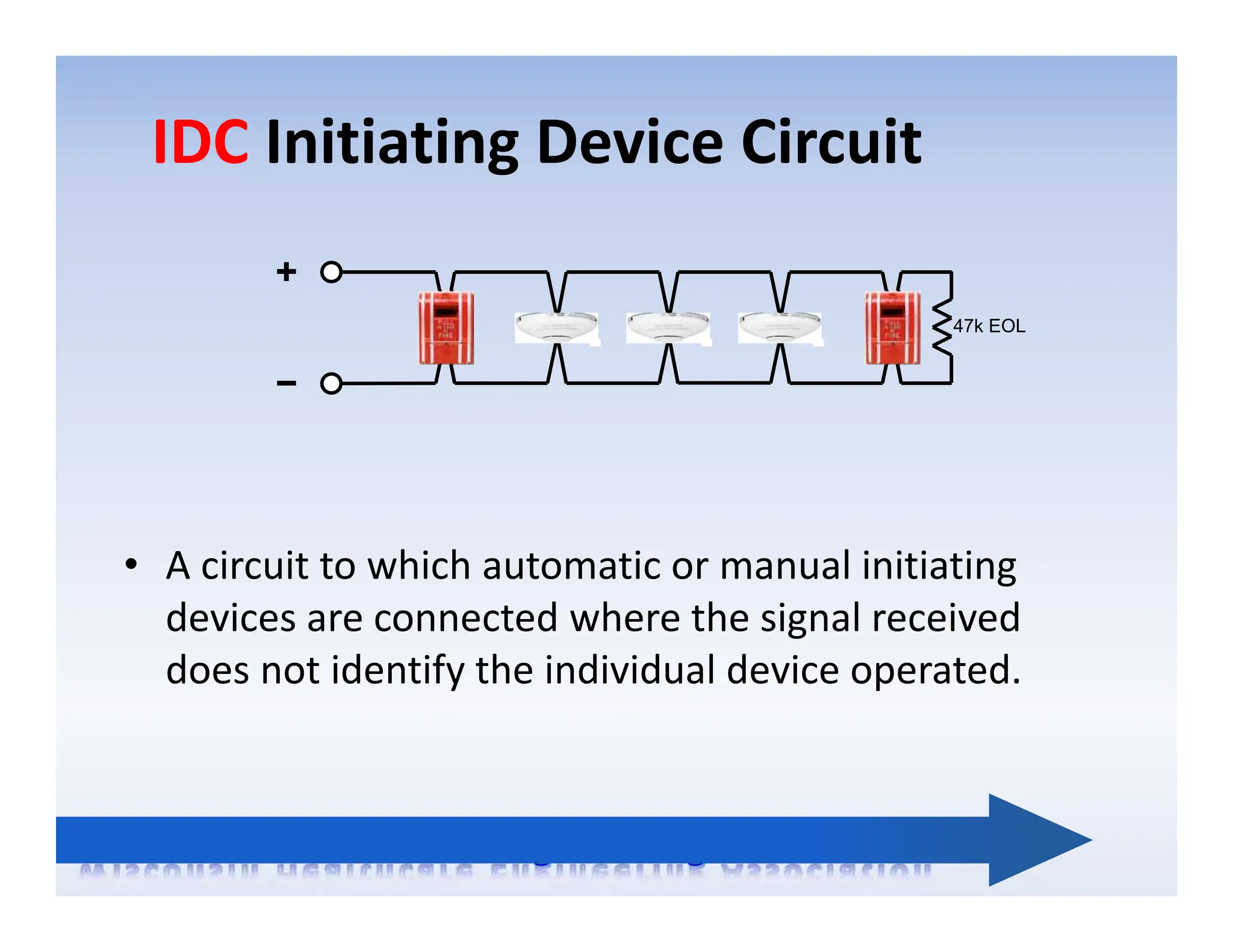

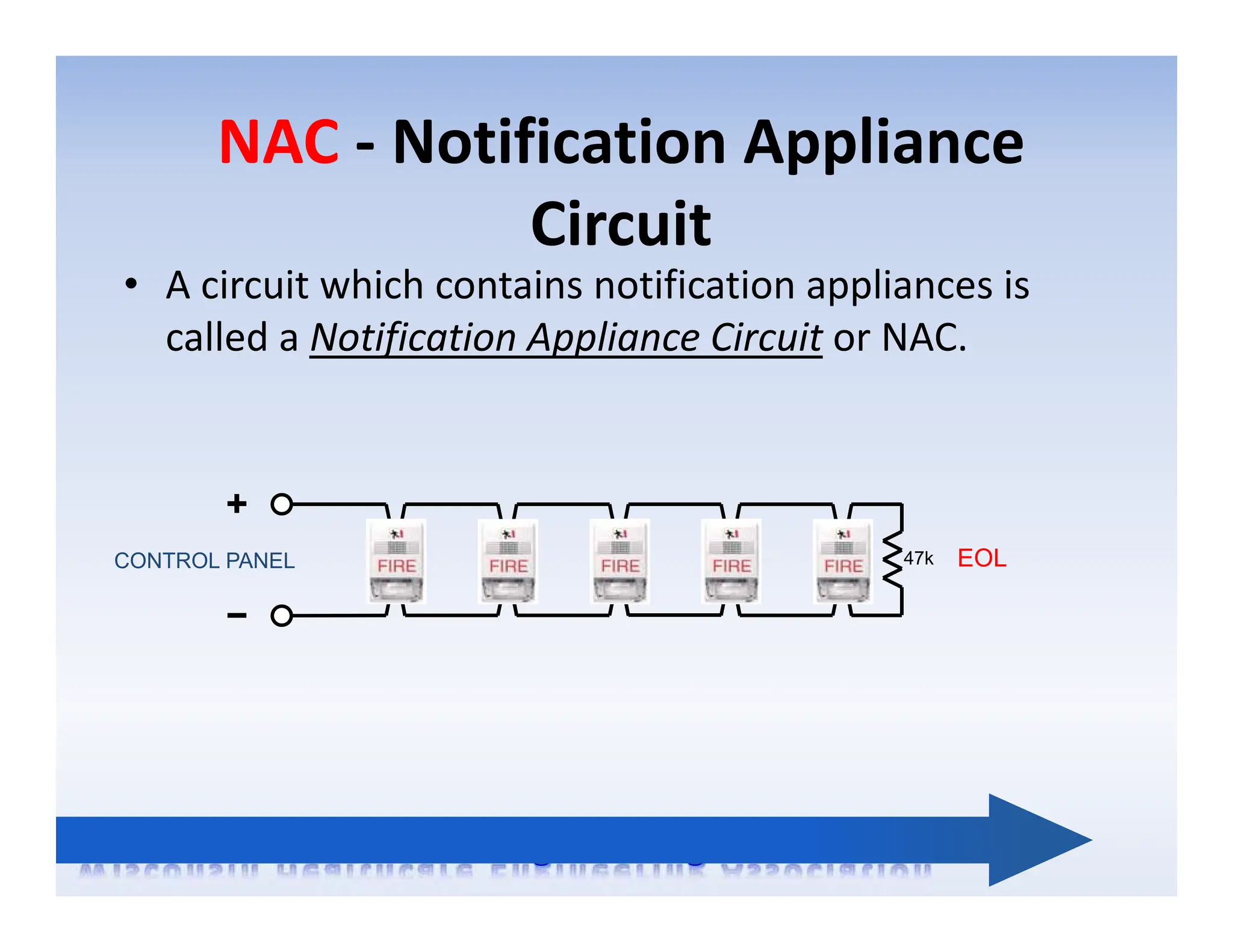

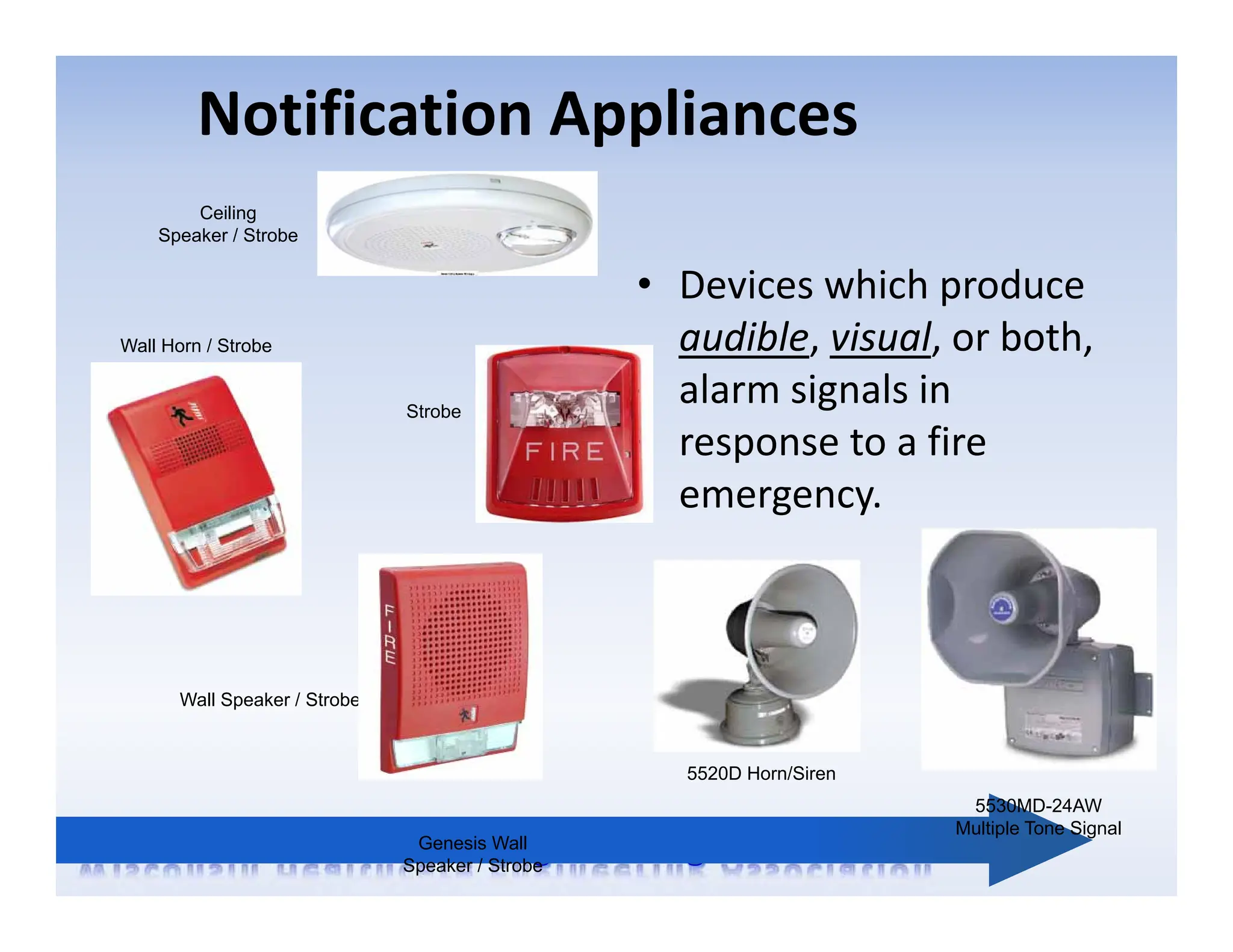

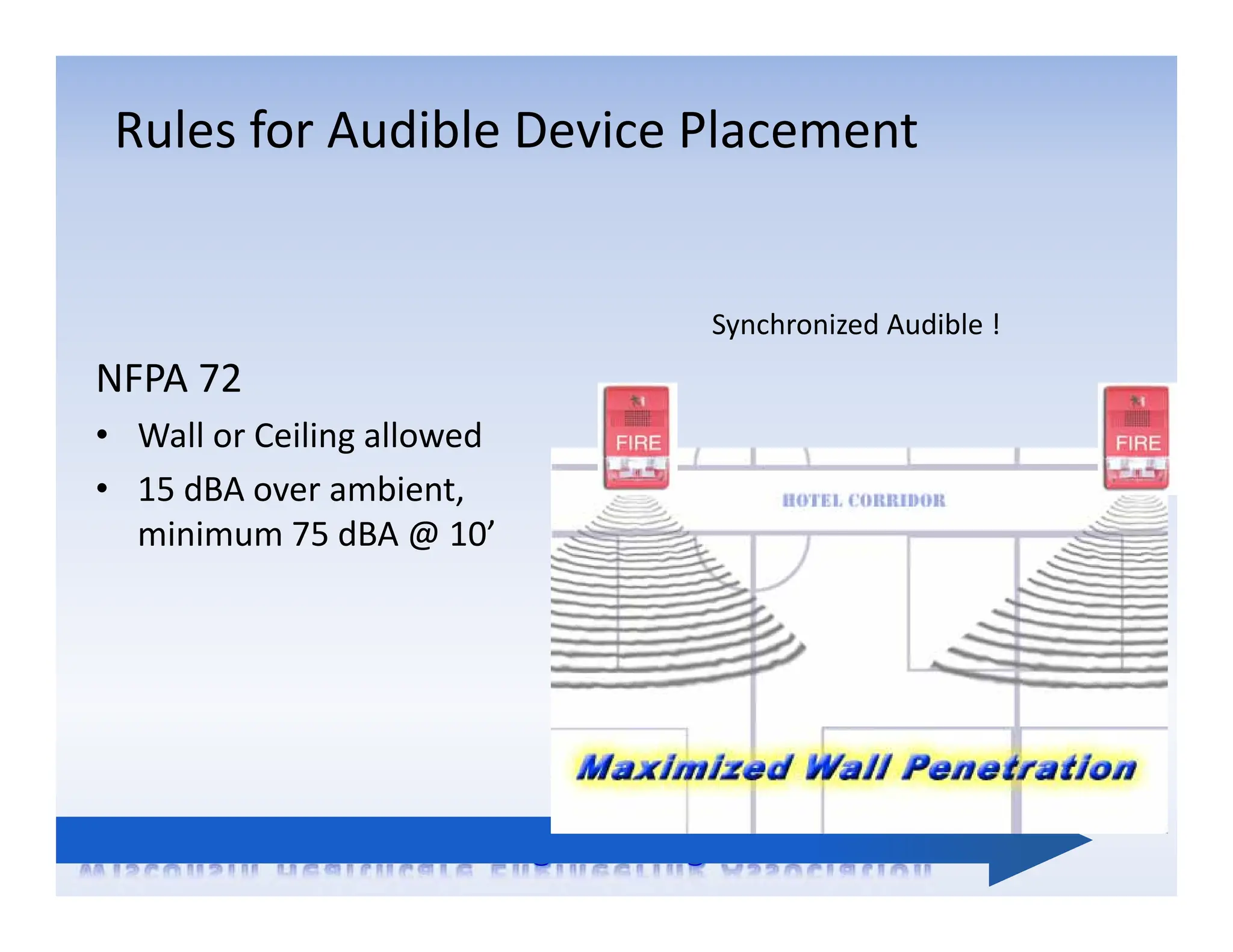

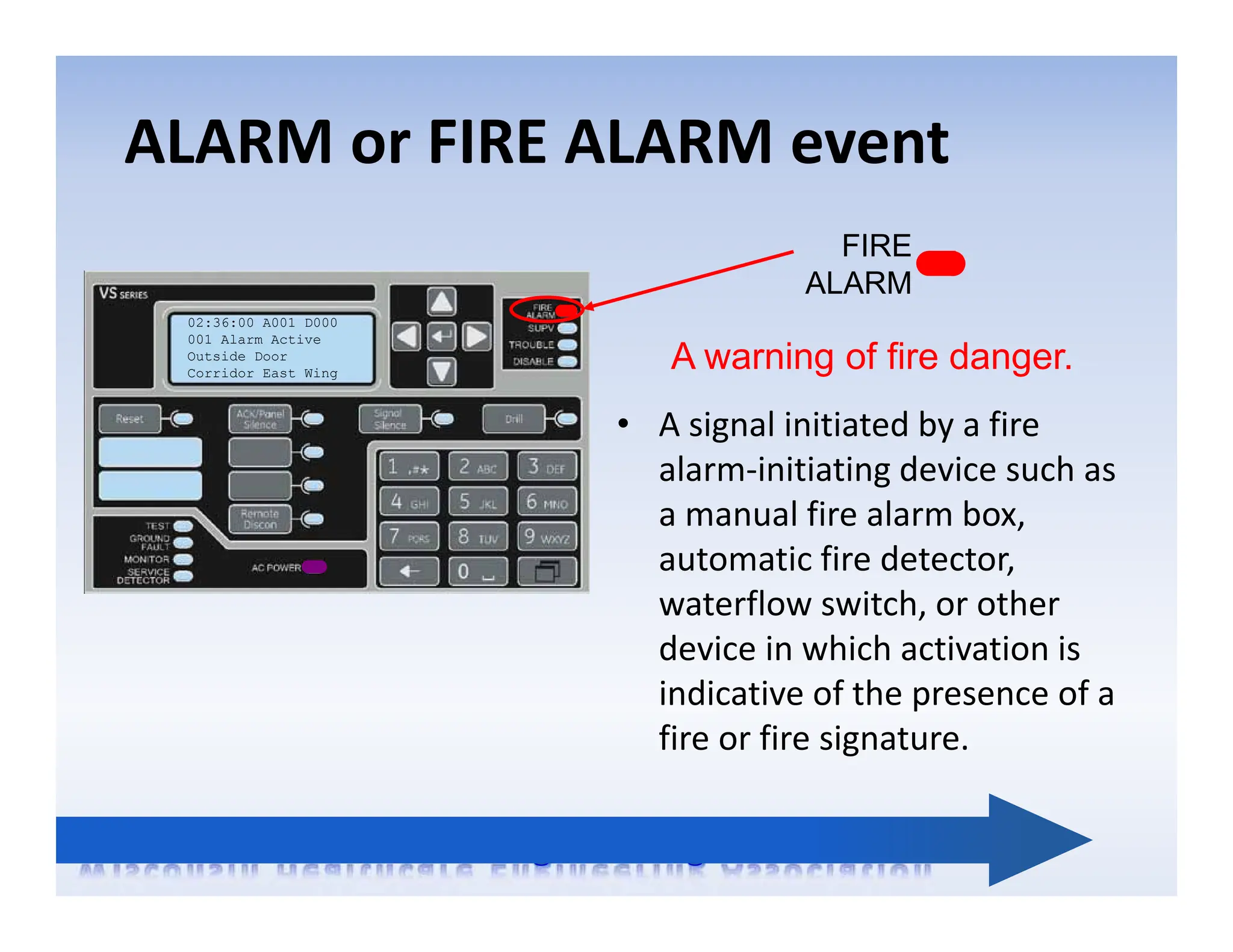

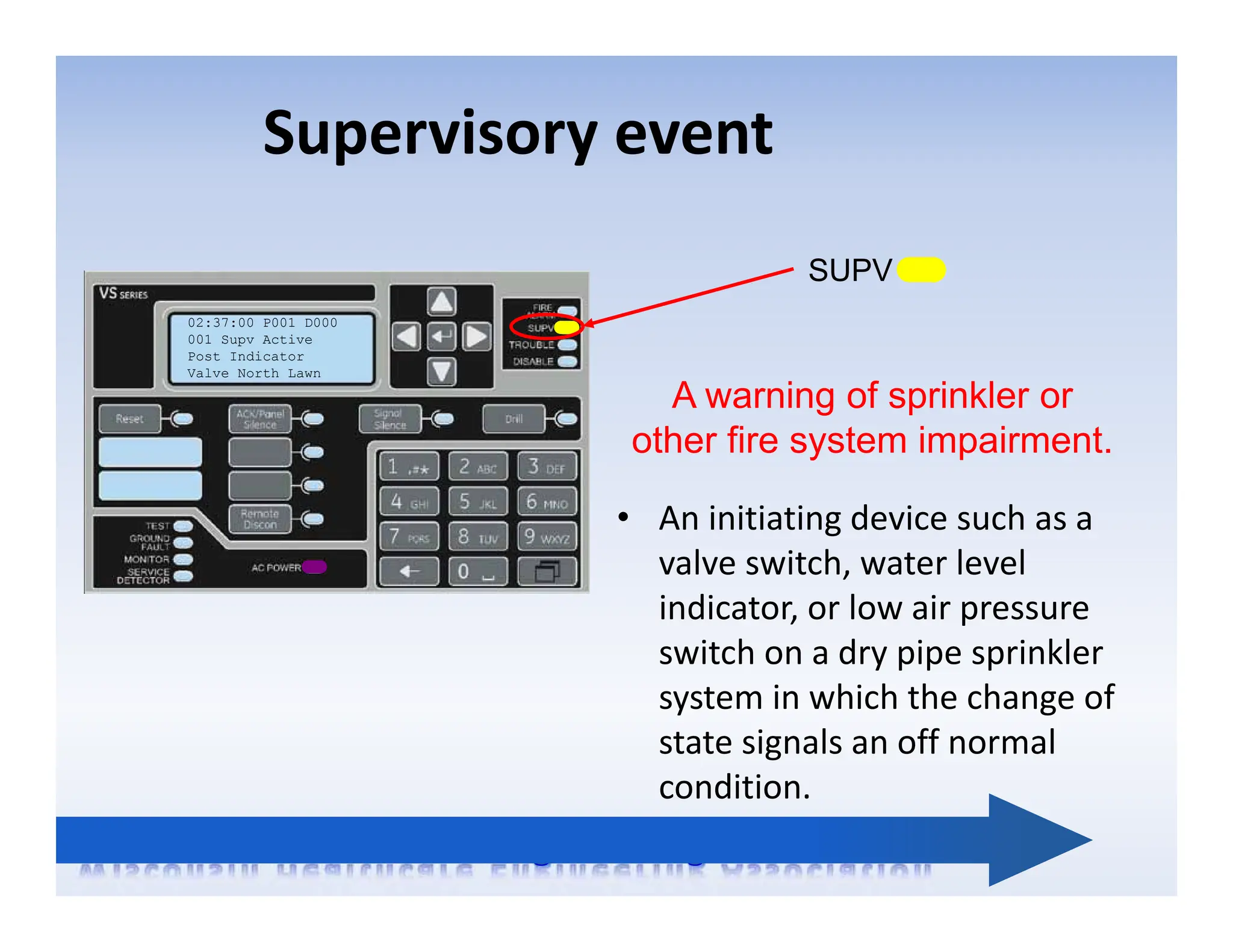

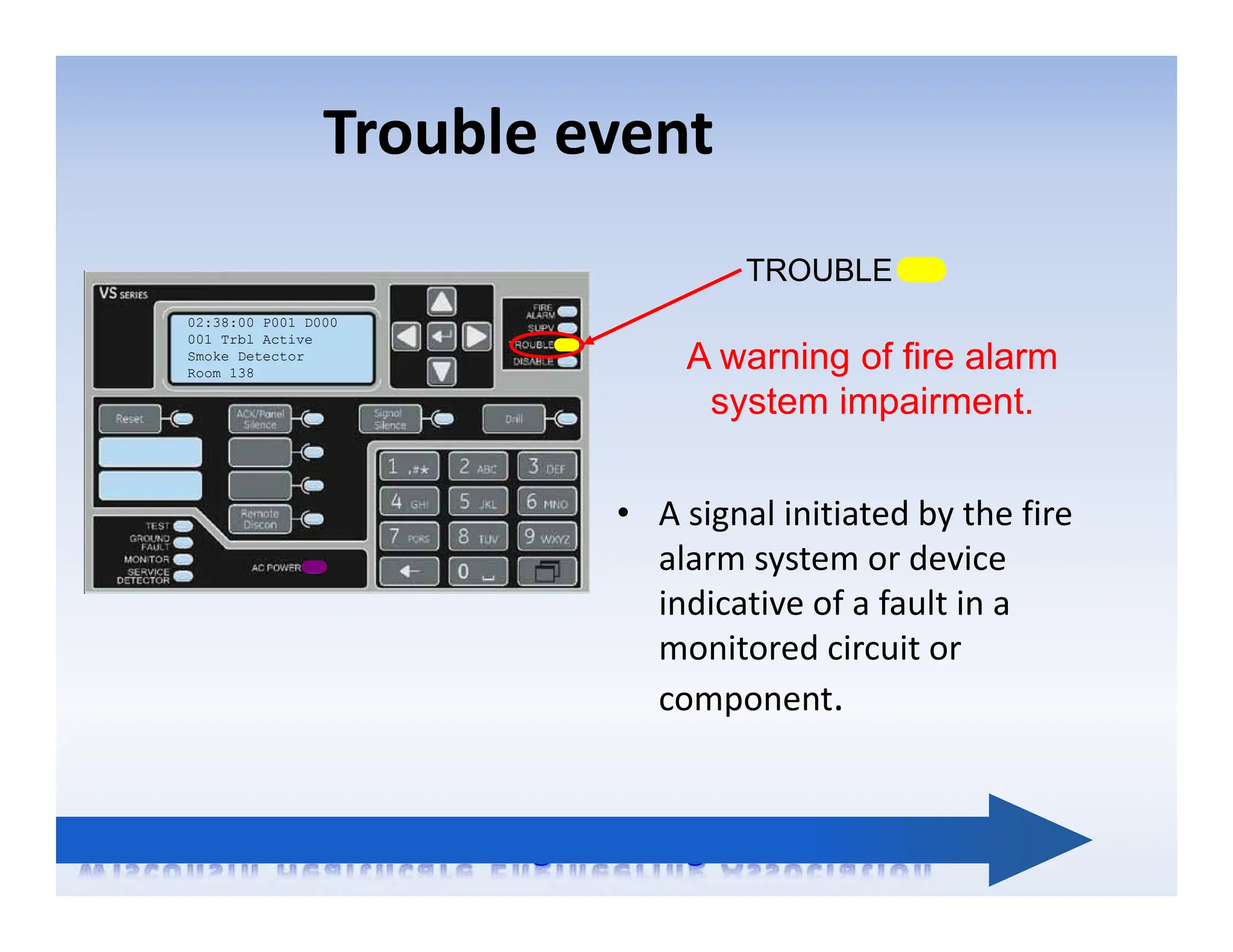

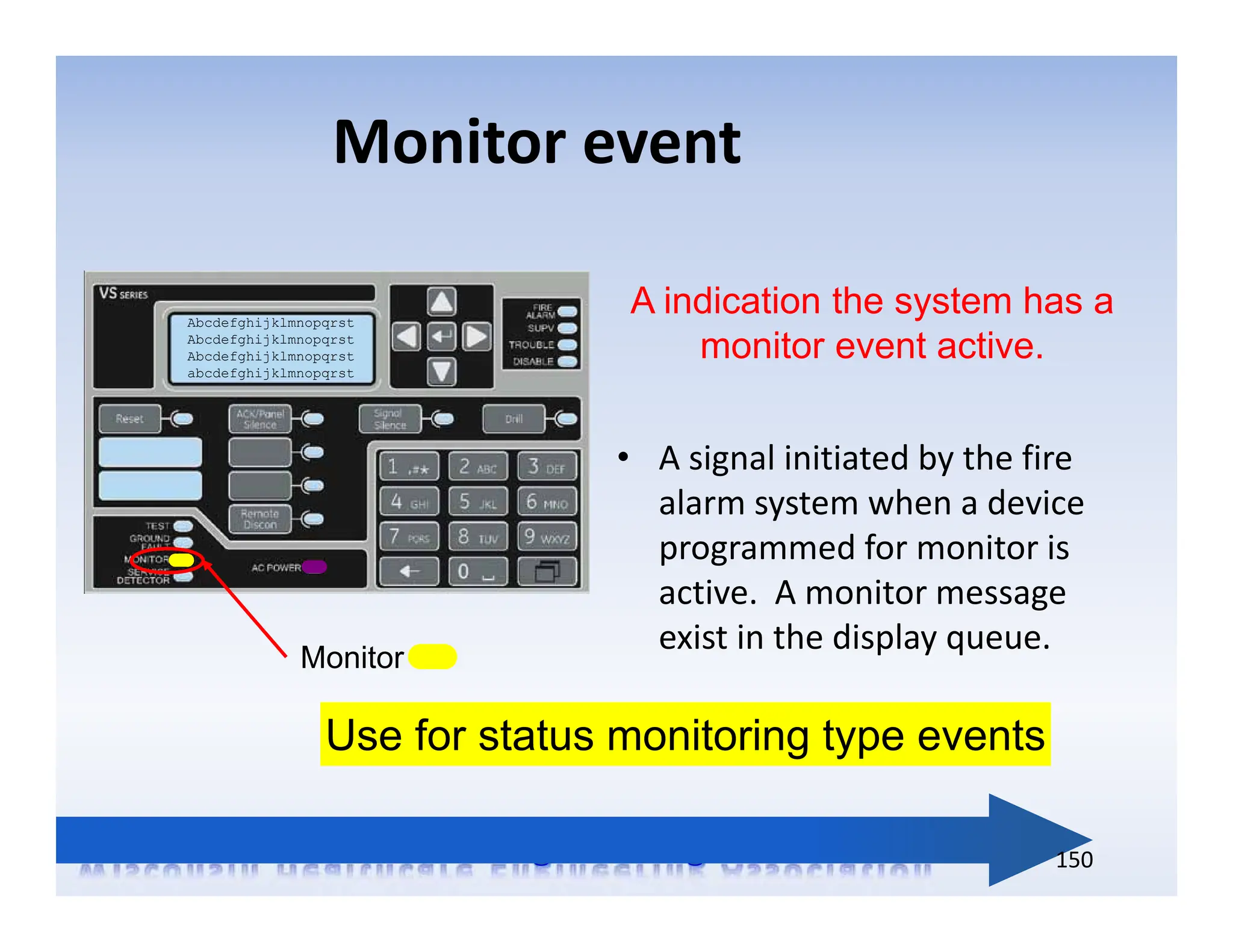

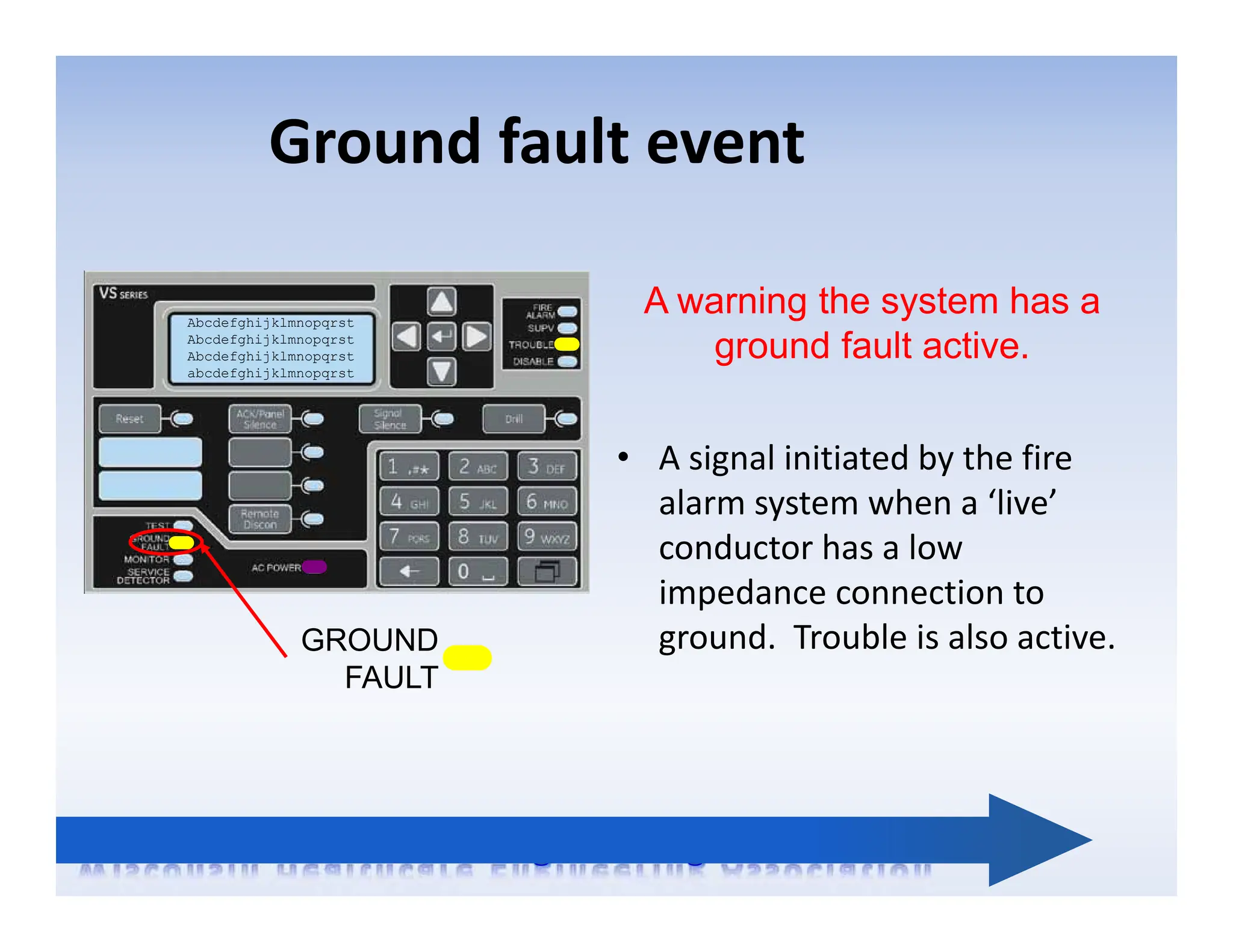

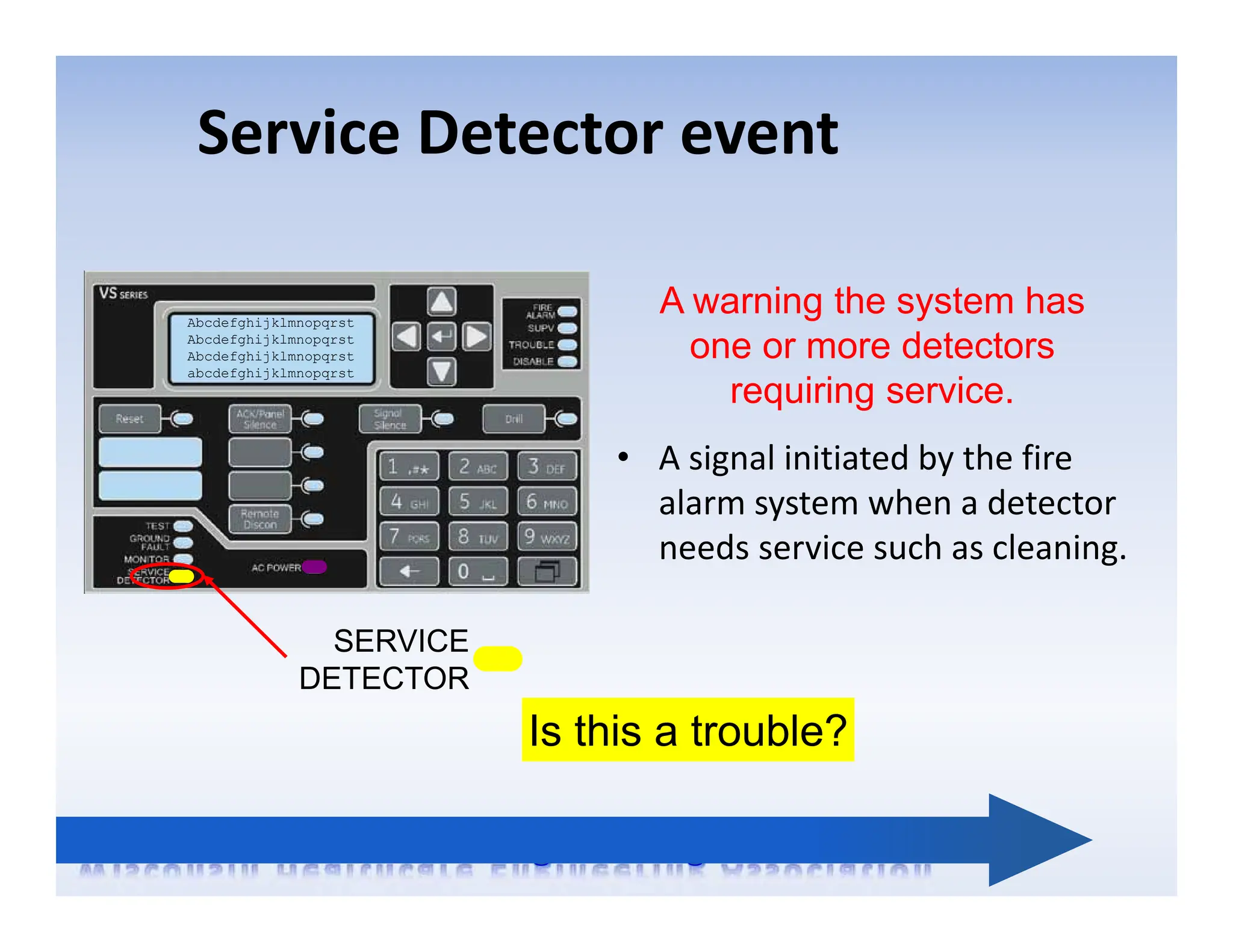

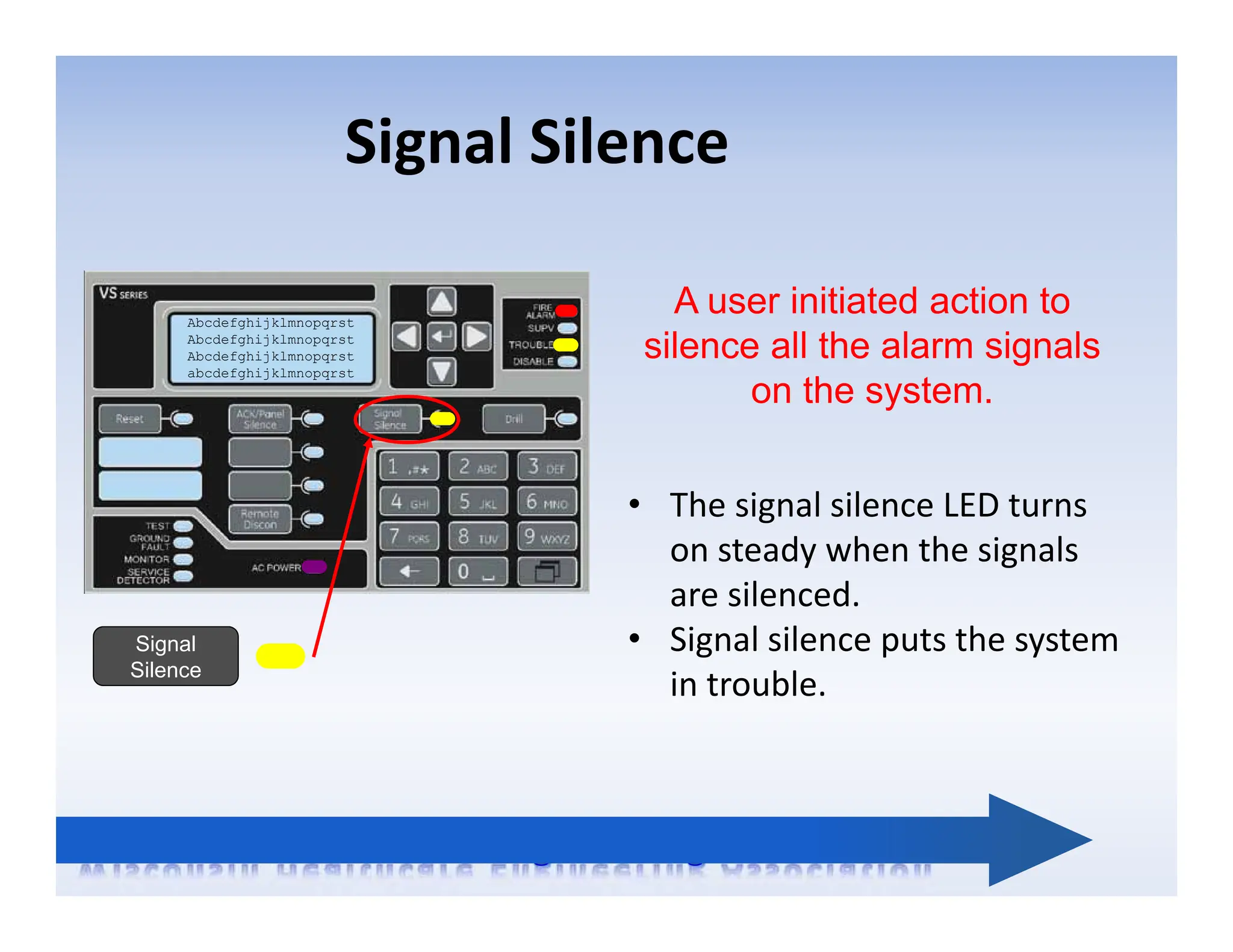

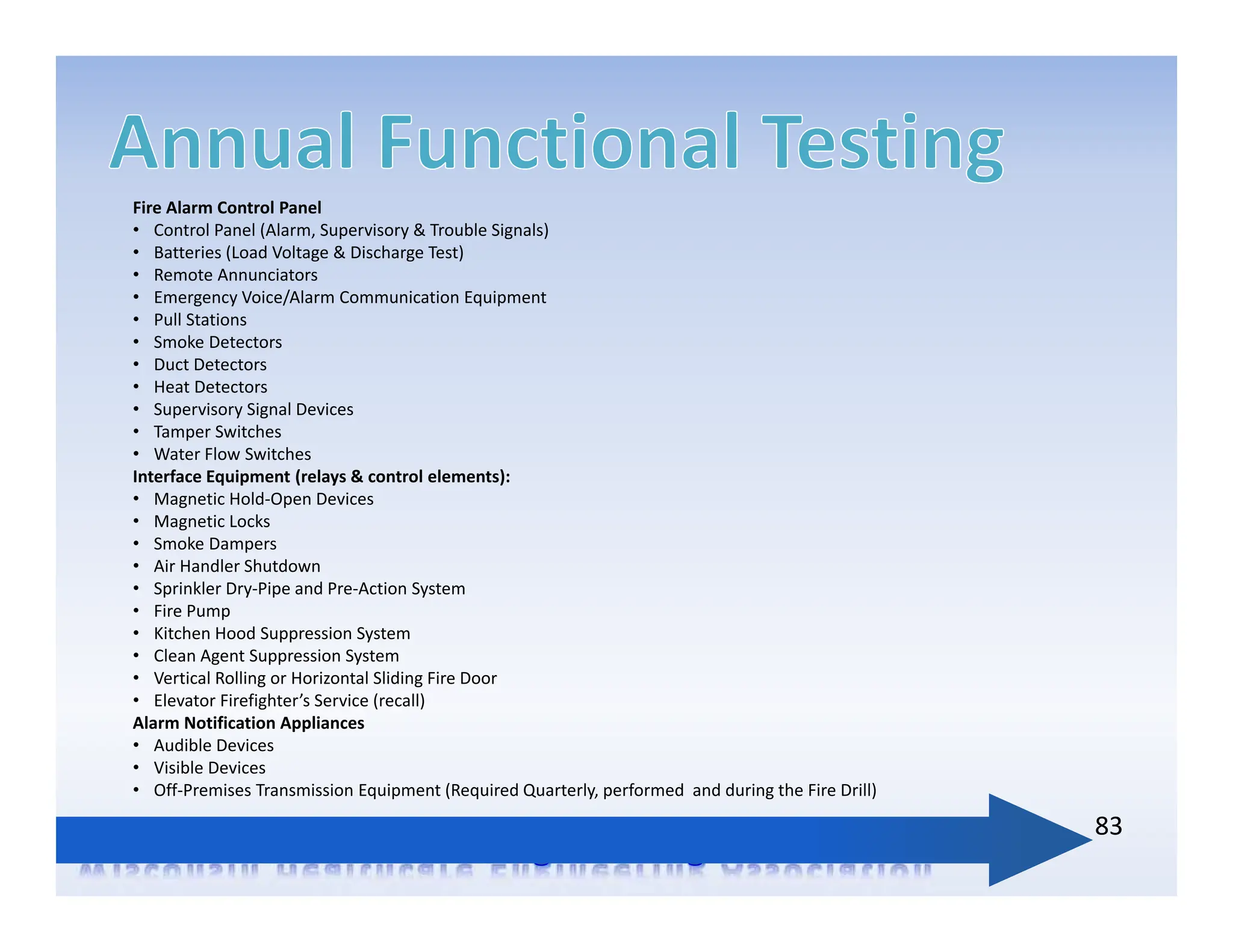

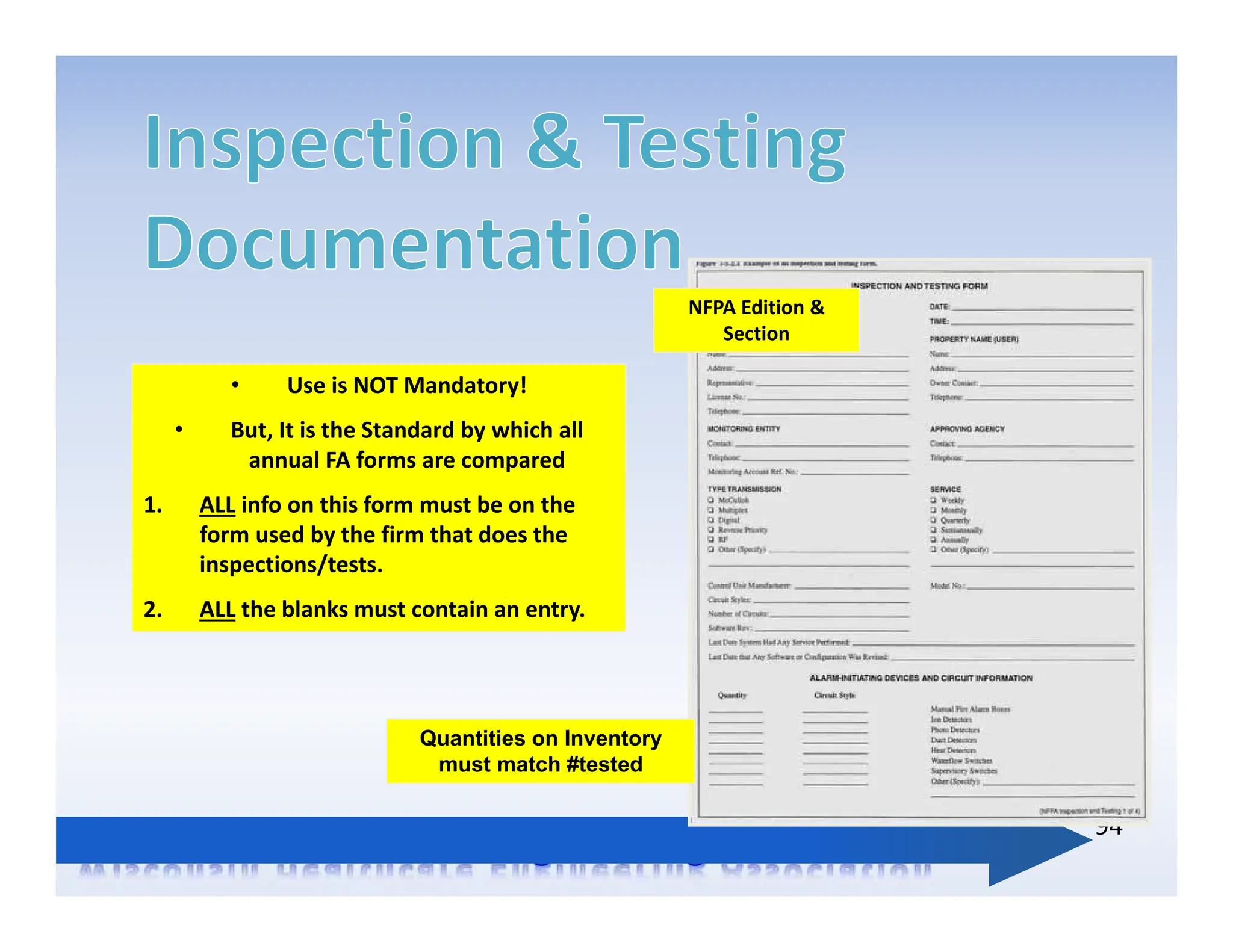

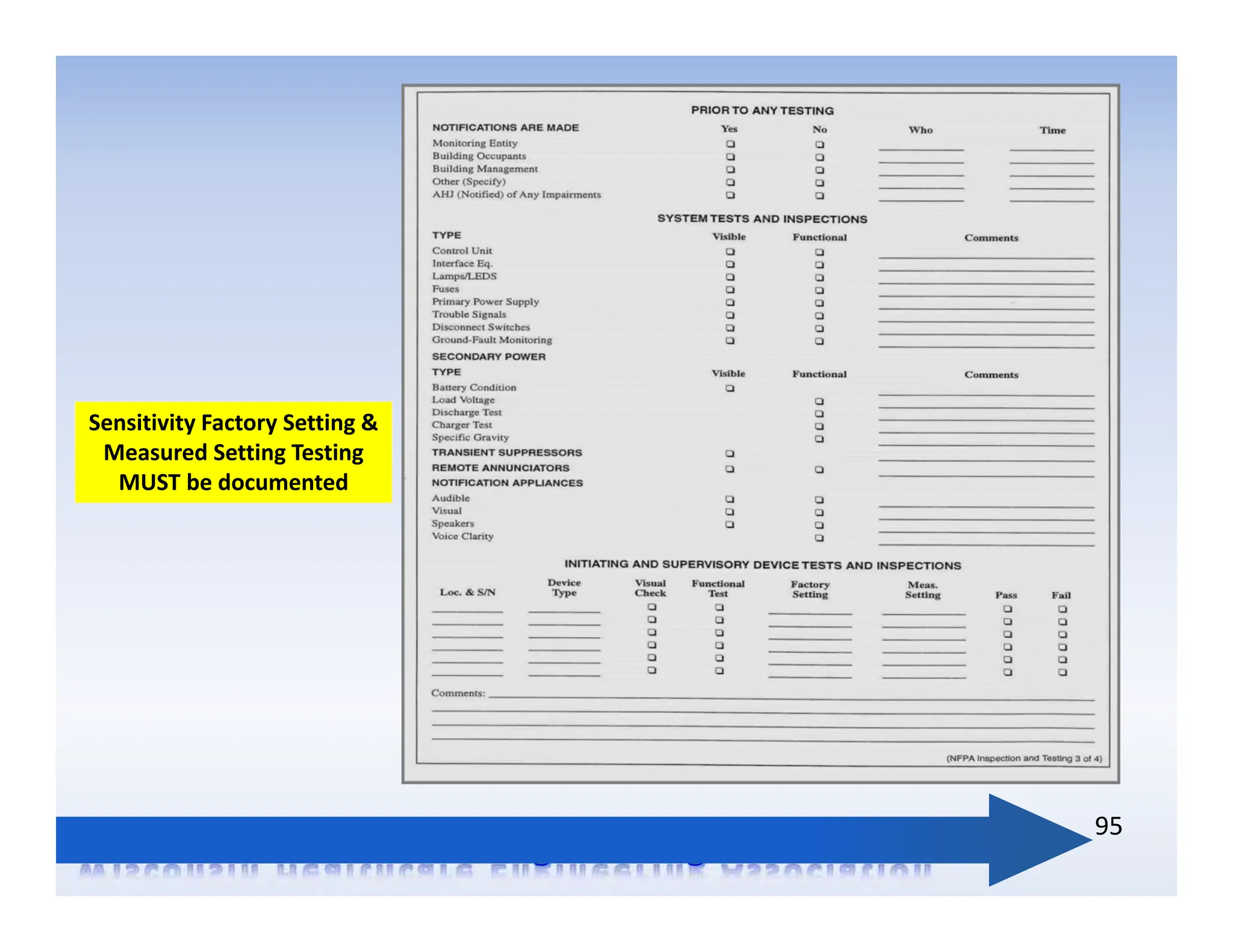

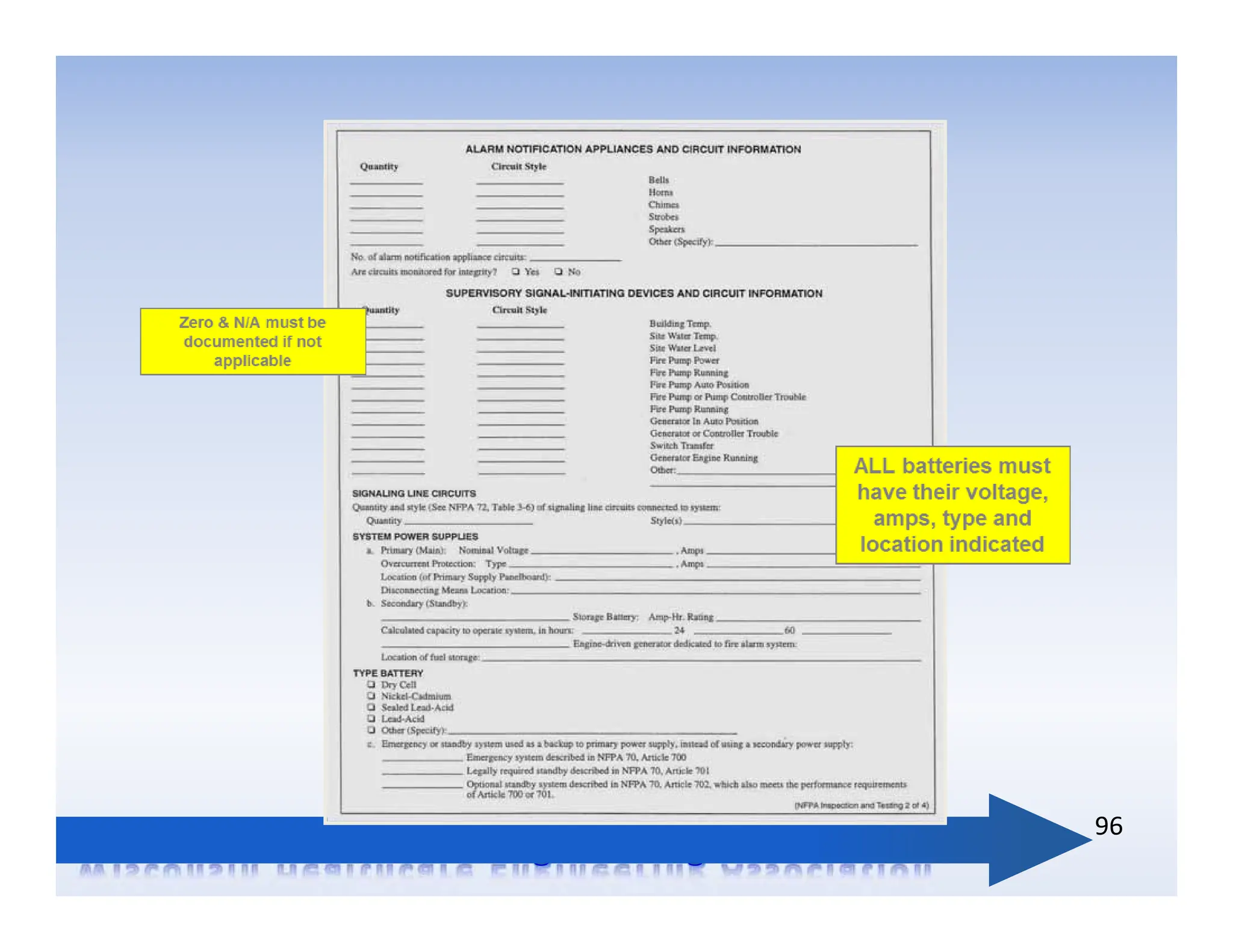

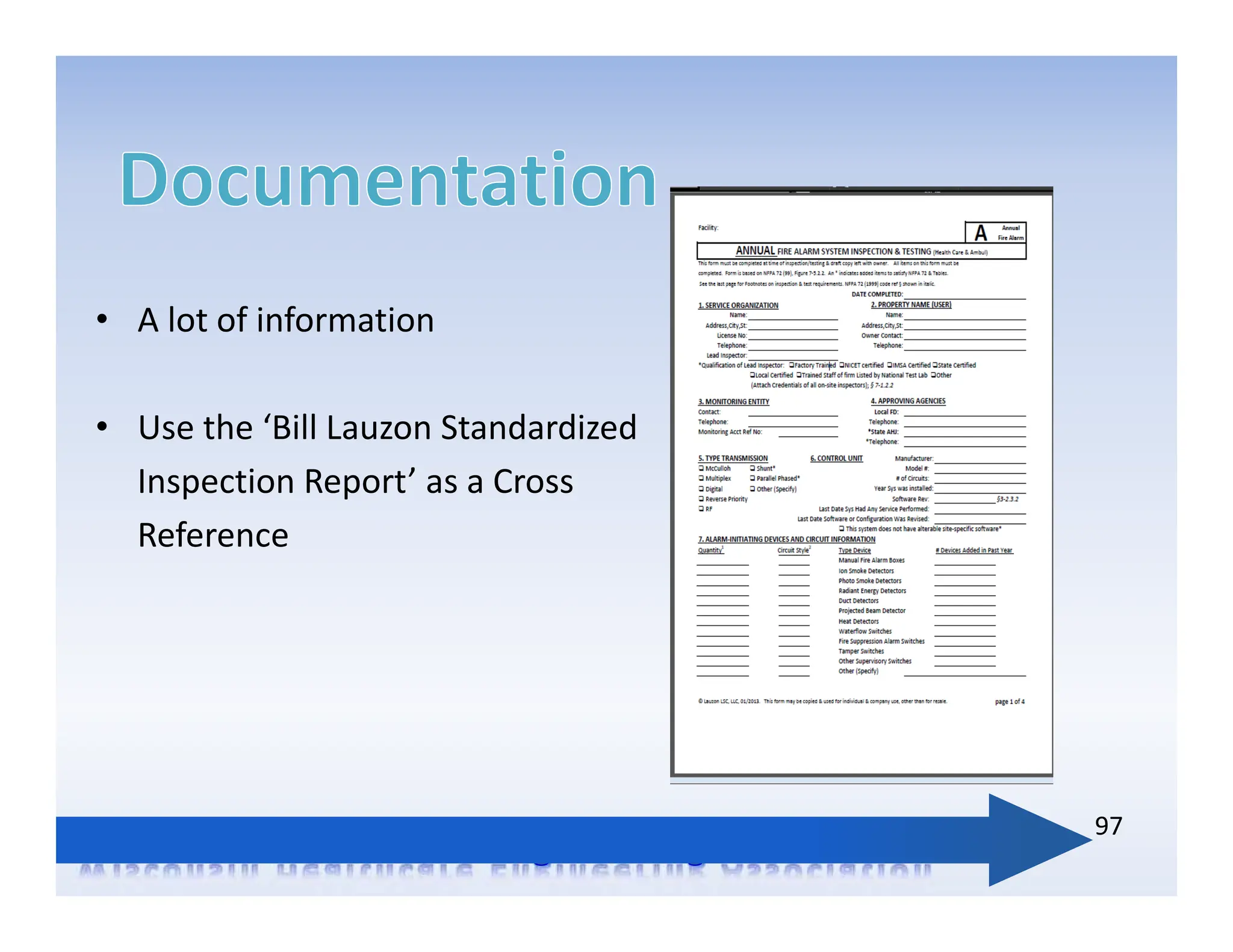

The document provides a comprehensive overview of fire alarm systems, detailing their main components, types of circuits, initiating devices, and installation guidelines. It covers various alarm events, including alarms, supervisory events, and monitoring details, emphasizing the importance of proper installation and maintenance of detection devices. Additionally, it outlines the necessity for visual notification appliances to accommodate individuals with hearing impairments in compliance with ADA standards.

![• Check for building modifications, occupancy changes, environmental

conditions, orientation, obstruction, damage, proper install) [7‐1.1]

• Sealed lead acid batteries must measure load voltage with charger

disconnected.

101](https://image.slidesharecdn.com/firealarmbasicinstallation-240530180821-f2160a84/75/The-Fire-Detection-and-the-alarm-system-101-2048.jpg)