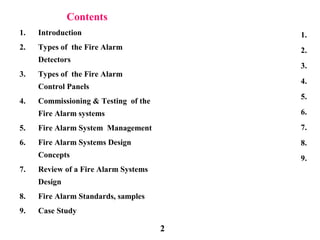

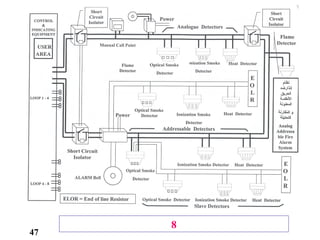

This document discusses different types of fire alarm detectors, including:

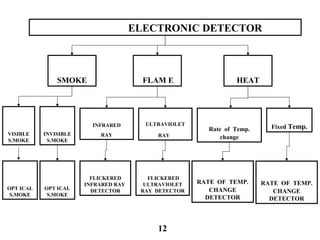

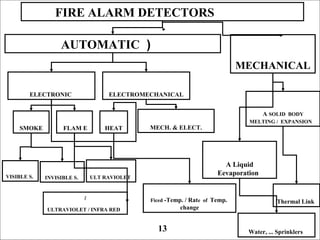

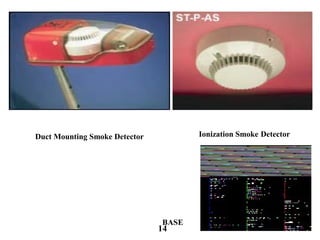

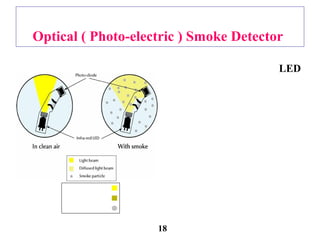

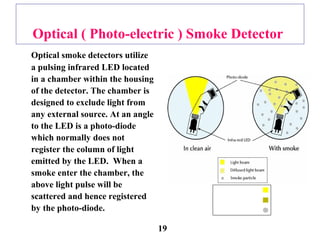

- Optical smoke detectors that detect smoke particles scattering a light beam.

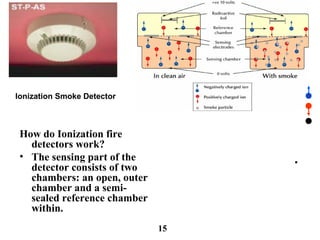

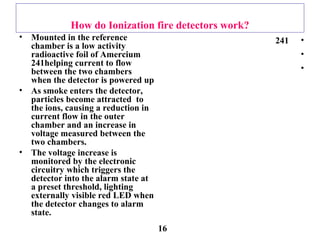

- Ionization smoke detectors that detect changes in air ionization from smoke particles.

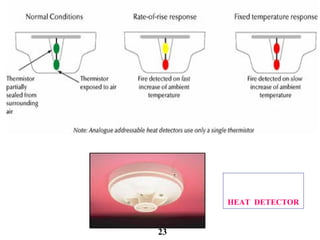

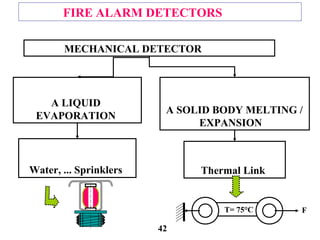

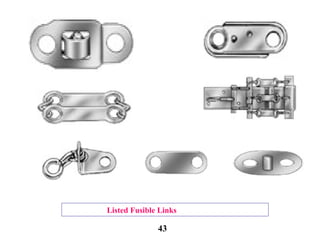

- Heat detectors that trigger when one thermistor is exposed to higher temperatures than another reference thermistor.

- Flame detectors that are sensitive to infrared or ultraviolet radiation from flames.

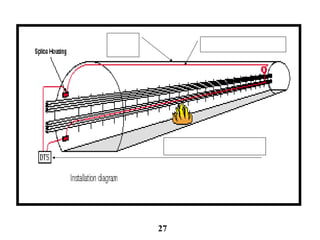

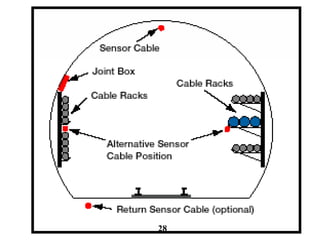

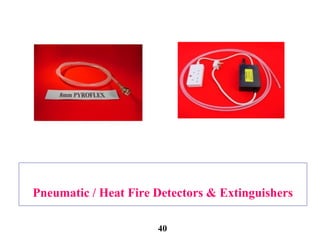

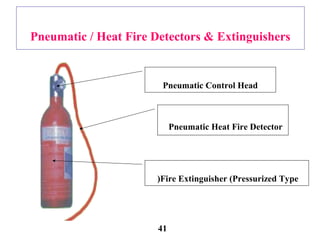

- Linear heat detectors that can detect heat along their entire length to protect large areas.

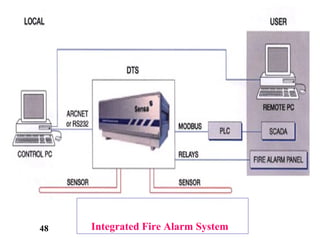

- Distributed temperature sensing uses fiber optic cables to continuously monitor temperature along their length and pinpoint the location of fires.

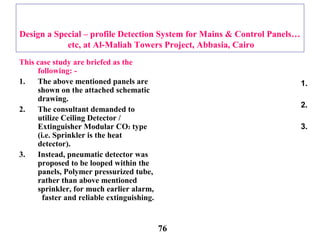

![Review a Design of a Fire Alarm System

4. Air-conditioning and ventilation

drawings ] To ensure early smoke

detection for the air sucked by the

air-conditioning ... etc hence

special duct smoke detectors must

be employed ( or a continuous air

sample must be drawn for early

smoke detection ). Moreover it

enables the design reviewer to

determine the dimensions and ducts

roots to ensure that it forms no

obstacles similar to the falling slabs.

5. A primary design review to the

available fire alarm detectors

distribution.

a. The number and types of the

detectors according to E.S ,

B.S. & NFPA.

b. The fire alarm zones according

to E.S., B.S. & NFPA.

4.

5.

.

67](https://image.slidesharecdn.com/firealarmsystems-171107014314/85/Fire-alarm-systems-67-320.jpg)