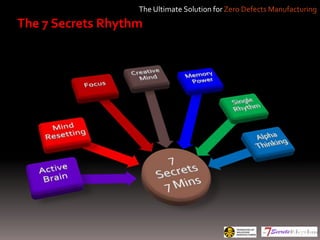

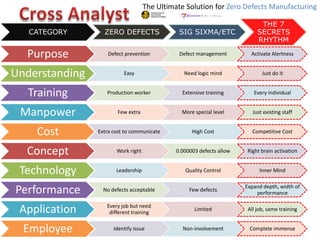

The document discusses a philosophy of zero defects manufacturing, emphasizing the importance of intrinsic techniques to prevent quality defects in production processes. It outlines historical developments in quality management from the 1960s to the 21st century, including Total Quality Management and Six Sigma. The author highlights the necessity of leadership, proper training, and acknowledgment of limitations to achieve high-quality outcomes in industrial settings.