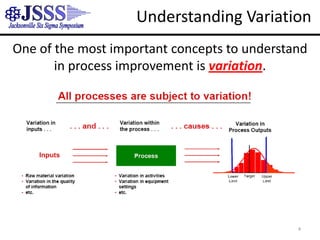

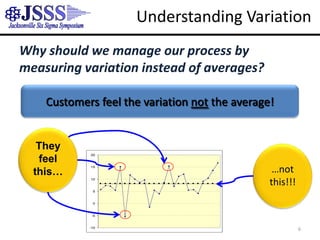

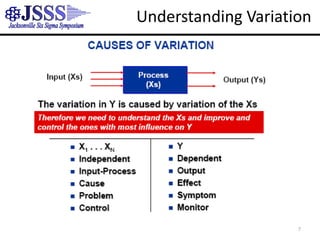

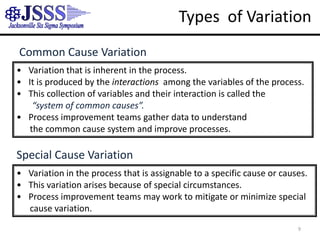

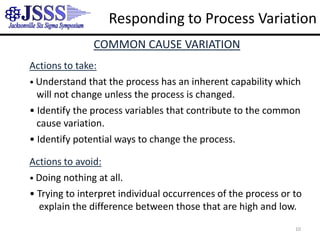

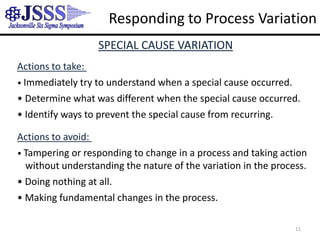

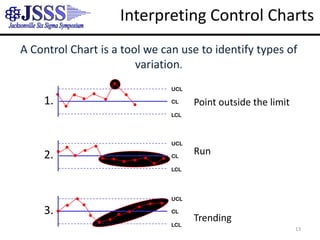

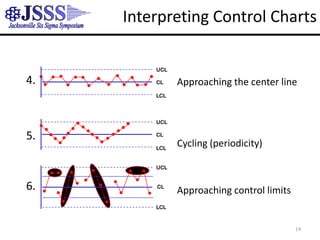

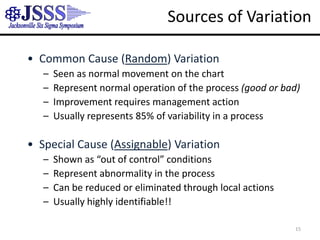

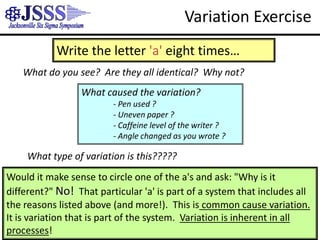

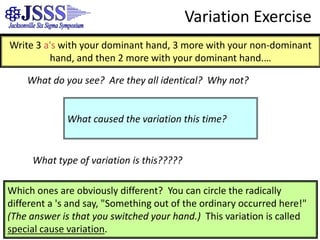

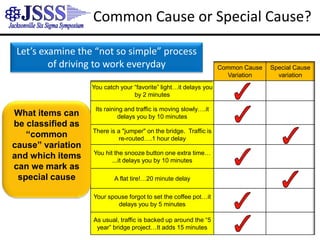

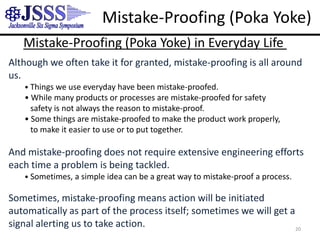

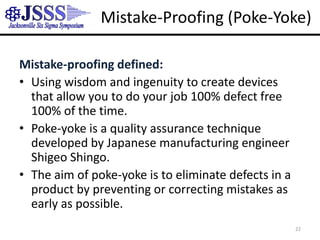

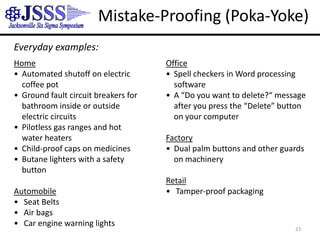

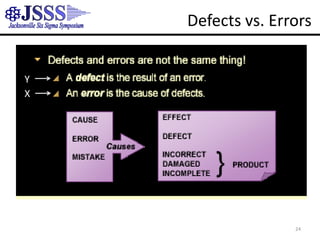

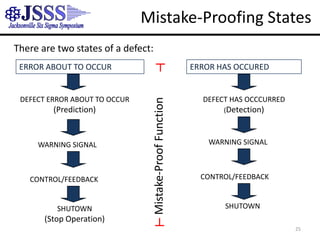

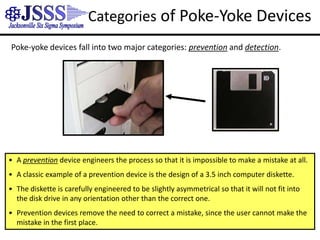

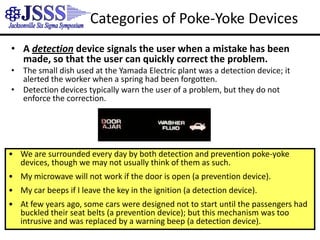

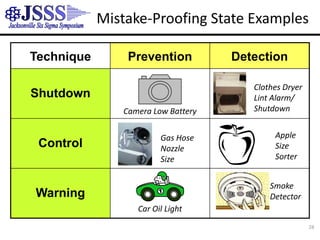

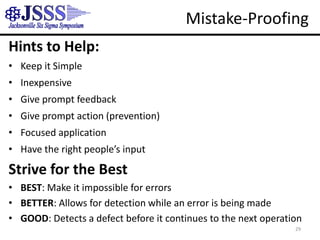

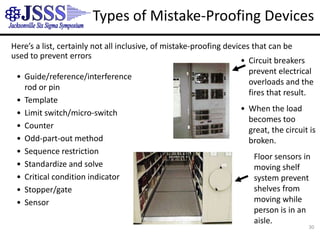

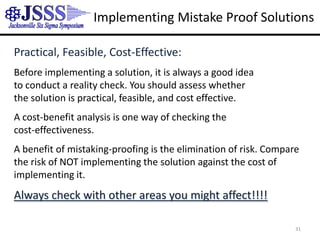

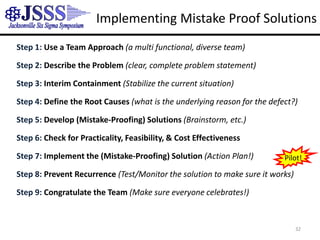

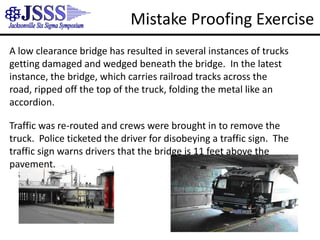

This document outlines the principles of continuous process improvement, focusing on variation and mistake-proofing. It explains the types of variations—common cause and special cause—and the significance of managing these variations for improving customer experience, alongside methods for mistake-proofing processes to prevent errors. Additionally, it offers practical steps for implementing mistake-proofing solutions within a team setting.