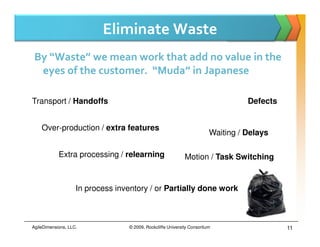

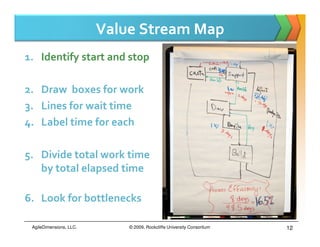

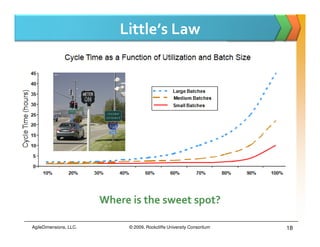

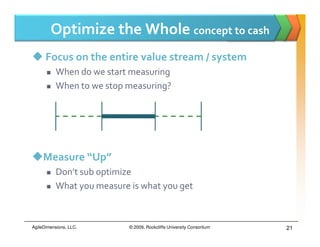

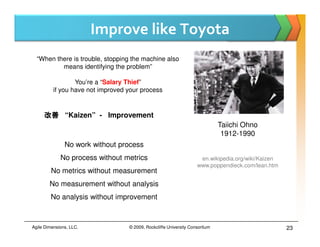

This document discusses concepts related to lean software development. It begins by explaining the origins of lean thinking at Toyota and how it was adapted to software development. It then outlines seven principles of lean software development: eliminate waste, build quality in, create knowledge, defer commitment, deliver fast, respect people, and optimize the whole. For each principle, it provides examples and explanations of how to apply that principle. It also includes discussions of related topics like value stream mapping, Little's Law, and continuous improvement.