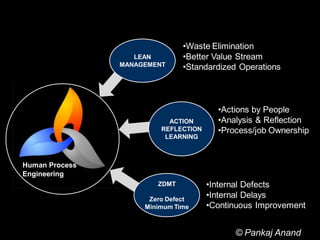

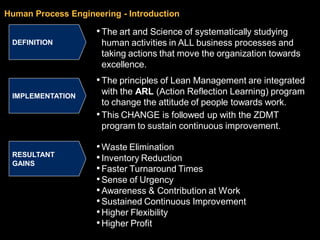

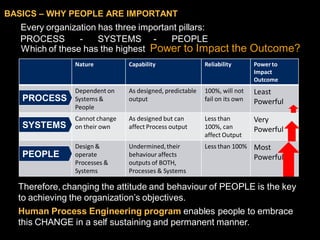

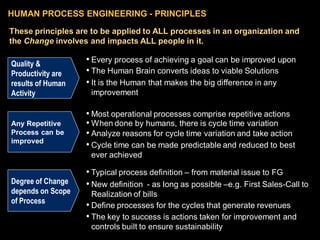

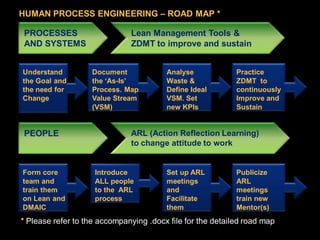

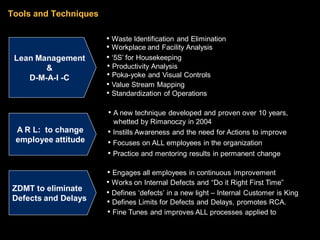

The document discusses human process engineering as a method to achieve operational excellence in organizations by systematically analyzing and improving human activities within business processes. It emphasizes the importance of changing employee attitudes and behaviors through programs like ARL (Action Reflection Learning) and ZDMT (Zero Defects and Minimum Time) to sustain continuous improvement and eliminate waste. Additionally, it highlights the need for standardized operations, cycle time reduction, and effective waste elimination strategies, backed by the expertise of Pankaj Anand in lean management and engineering.