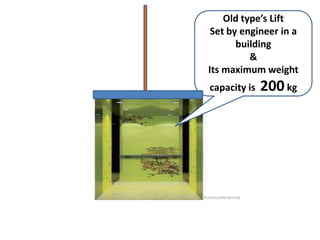

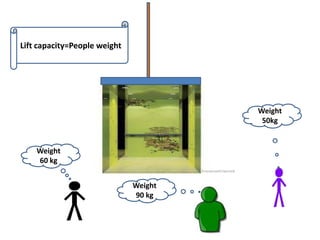

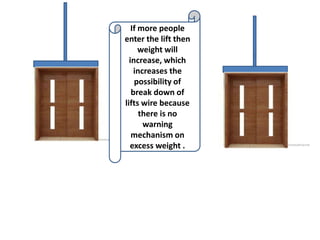

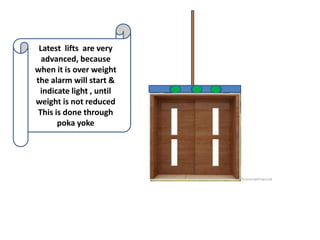

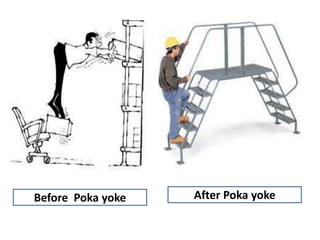

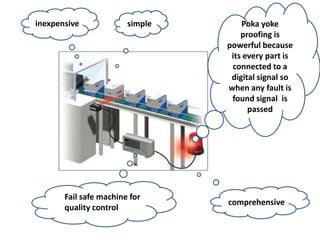

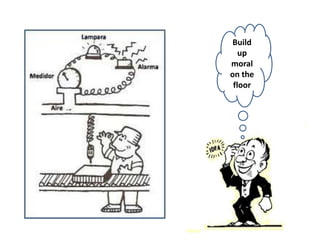

Poka-yoke is a Japanese term that means "mistake-proofing" and refers to mechanisms in manufacturing processes that help operators avoid errors. Its purpose is to eliminate defects by preventing, correcting, or drawing attention to human mistakes. Poka-yoke was developed by Shigeo Shingo at Toyota to achieve "zero defects" through fail-safe mechanisms. Examples include lifts that prevent overloading and include alarms if weight limits are exceeded. Implementing poka-yoke helps improve quality, productivity, and efficiency by reducing errors, rework, and waste in manufacturing processes.