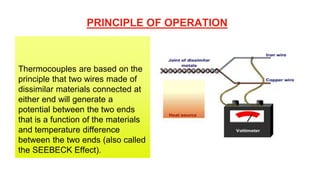

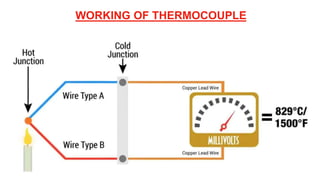

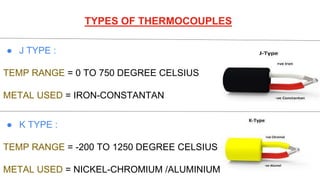

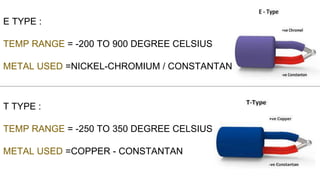

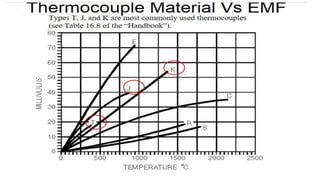

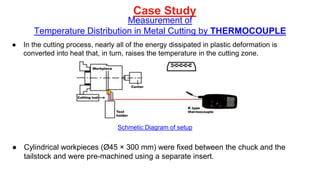

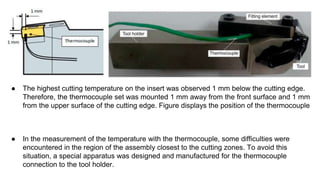

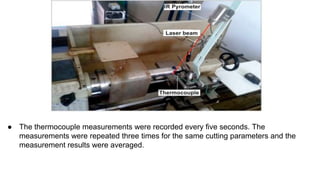

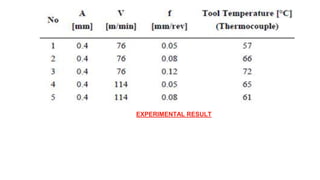

Thermocouples are temperature measurement devices that operate based on the Seebeck effect. They produce a voltage when two dissimilar metals are joined together at both ends and there is a temperature difference between the ends. Thermocouples have various applications in industries like steel, manufacturing and power plants. They are commonly used to measure temperature in metal cutting operations. An experiment measured the temperature distribution on a cutting tool during metal cutting using a K-type thermocouple and found that temperature was highest near the cutting edge and increased with cutting speed. Thermocouples have advantages of being rugged and having a wide temperature range but also have limitations like non-linear output and complexity.