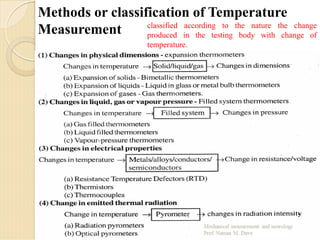

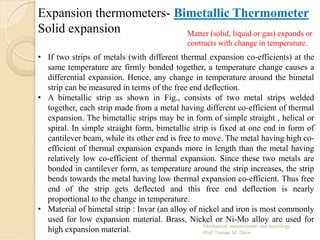

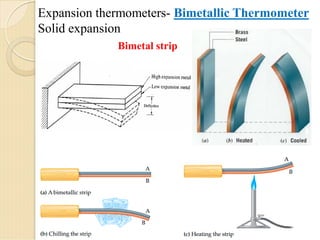

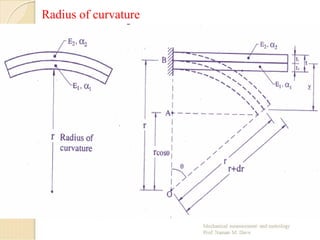

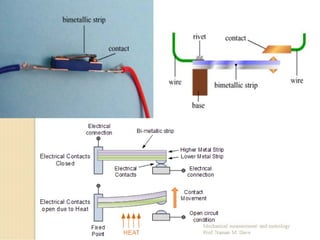

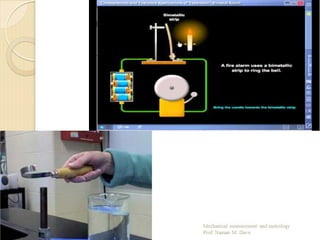

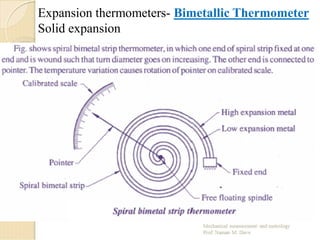

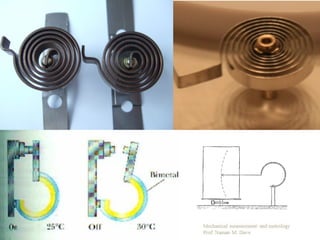

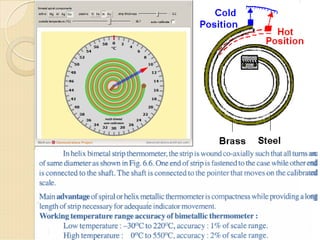

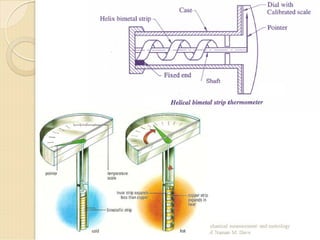

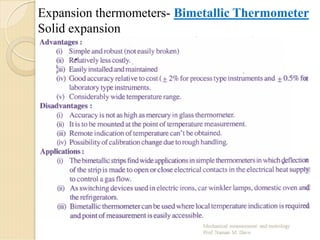

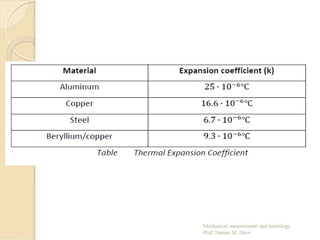

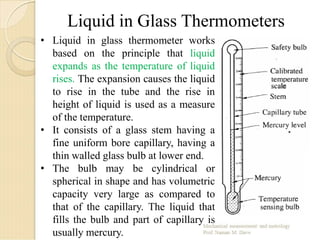

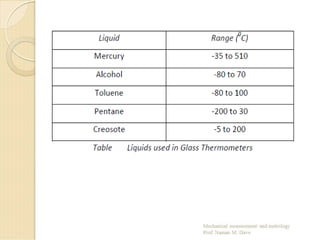

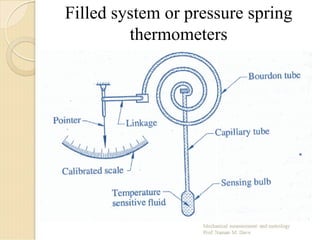

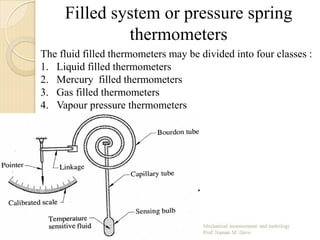

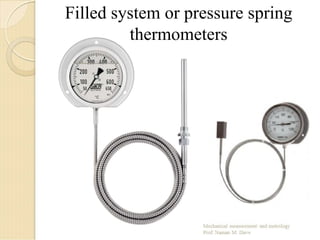

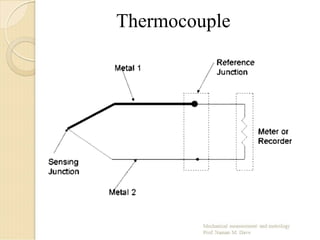

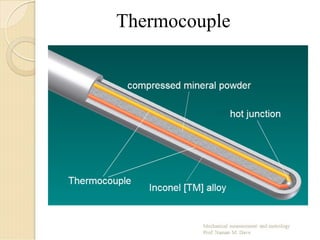

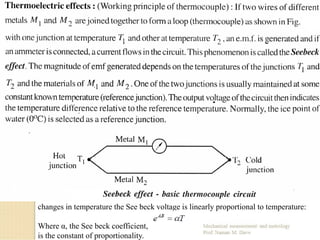

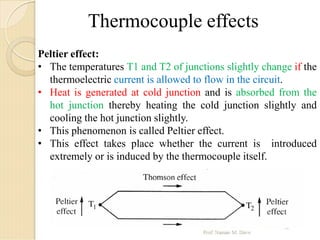

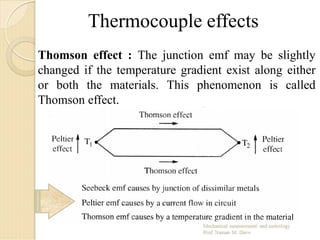

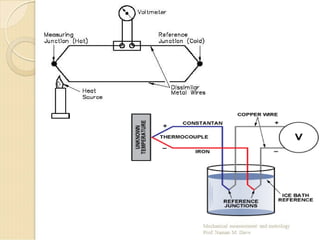

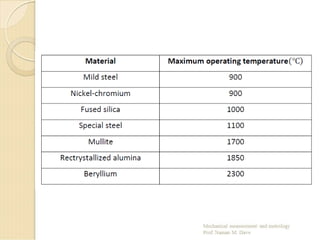

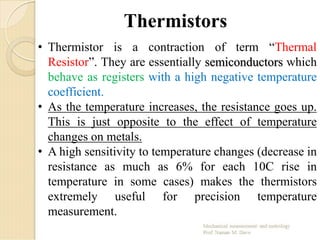

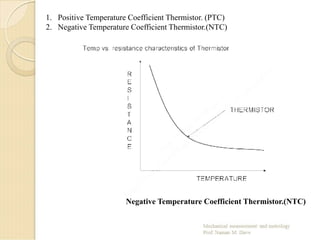

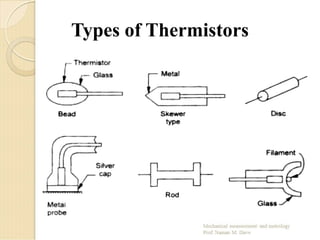

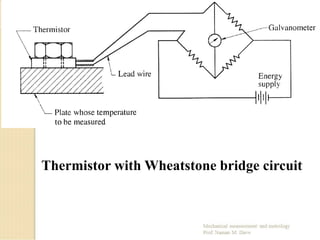

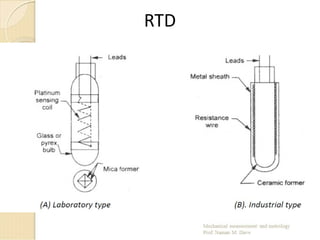

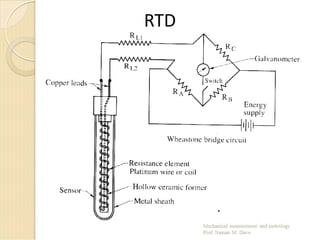

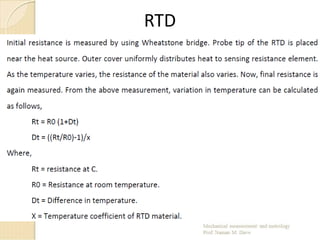

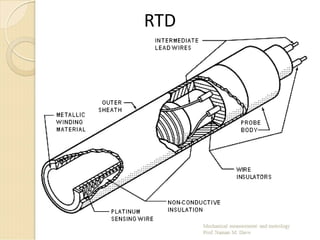

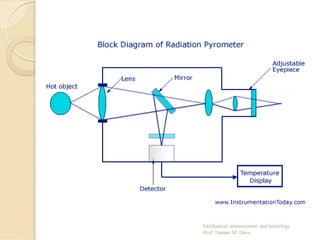

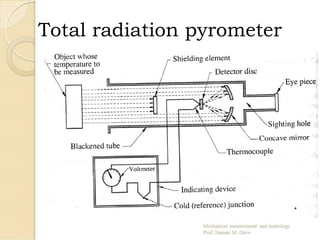

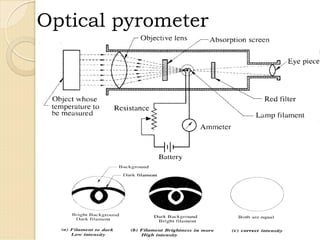

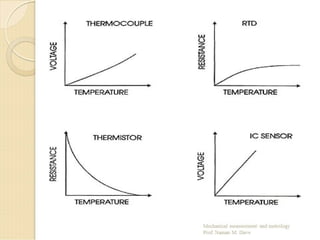

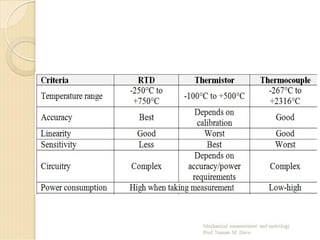

The document discusses various methods of temperature measurement, describing concepts such as the nature of temperature and its relation to heat flow. It covers different types of thermometers, including bimetallic, liquid in glass, filled system, and electrical instruments like thermocouples and thermistors, highlighting their principles and mechanisms. Additionally, it explains the characteristics and applications of these measurement devices, emphasizing their importance in temperature control and monitoring.