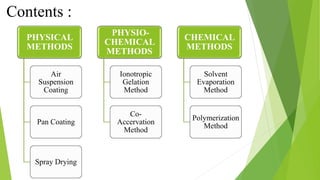

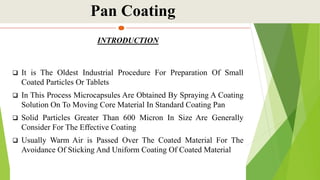

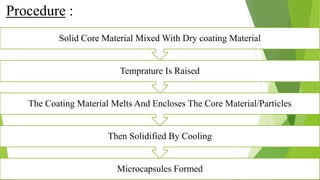

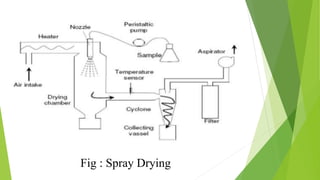

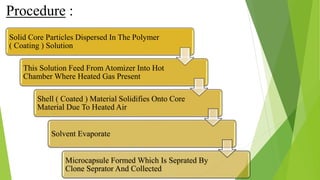

This document discusses various methods for microencapsulation, including physical methods (air suspension coating, pan coating, spray drying), physiochemical methods (ionotropic gelation, co-accervation), and chemical methods (solvent evaporation, polymerization). It provides details on the procedures and processing variables for each method. Physical methods involve applying coating material to solid core materials using air streams or moving pans, while chemical methods use polymerization or solvent evaporation to form microcapsule shells around core materials dispersed in solution.