This document discusses pharmaceutical aerosols, including their definition, components, types of systems, manufacturing, and quality control. Key points include:

- Pharmaceutical aerosols are systems that use compressed gases to expel medication from a container via valves. They were developed in the 1950s for topical and respiratory treatments.

- They have components like propellants, containers, valves, and product concentrates containing active ingredients and additives. Common propellants are fluorocarbons and hydrocarbons.

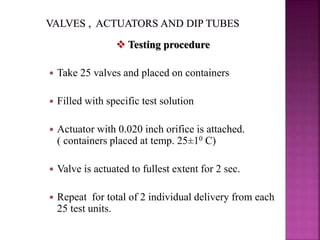

- Manufacturing involves formulating product concentrates and blending propellants to achieve the desired vapor pressure and particle size. Quality control testing evaluates the aerosol's physical and chemical properties.