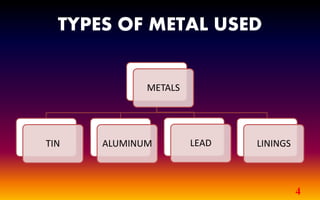

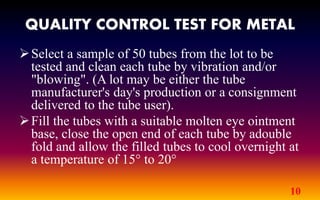

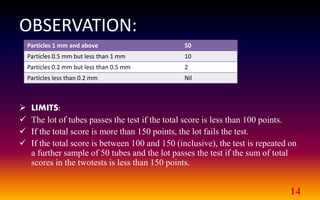

The document outlines quality control testing for metal containers used in packaging medicinal products. It discusses the advantages and disadvantages of various metals, primarily aluminum, tin, and lead, as well as the appropriate linings to prevent reactivity and maintain product integrity. Additionally, it details the testing procedure for assessing metal particle contamination in tubes, including a scoring system to determine pass or fail based on particle counts.