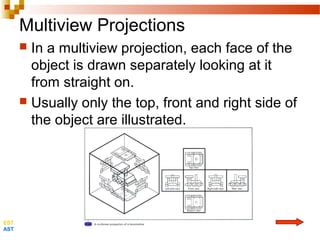

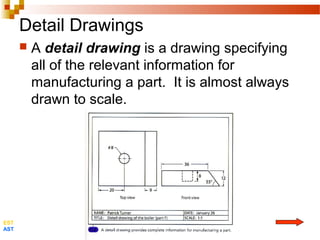

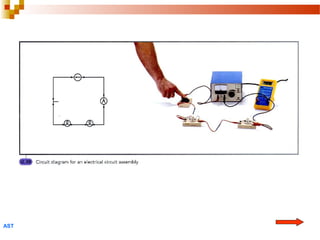

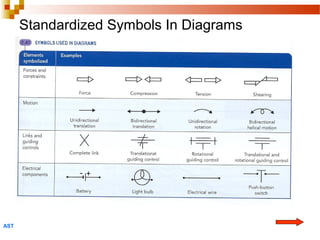

This document discusses technical drafting and manufacturing processes. It explains that technical drawings must be created to determine the shape and dimensions of an object before manufacturing. There are different types of projections used in technical drawings like isometric and multiview projections. Engineering drawings also include details like general arrangements, exploded views, and developments. Diagrams are then used to explain operating principles and manufacturing considerations. Finally, the document outlines the manufacturing process, including measuring and laying out parts, machining techniques such as cutting and drilling, and assembling and finishing the final product.