The document discusses various topics related to manufacturing technical objects including:

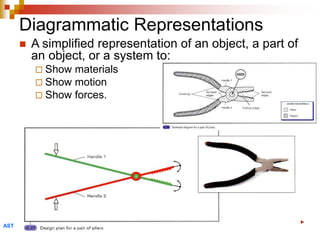

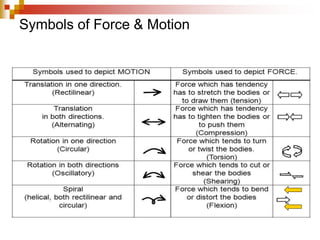

- Guiding components which control the motion of moving parts and can provide translational, rotational, or helical motion.

- Degrees of freedom which describe the possible independent movements of parts.

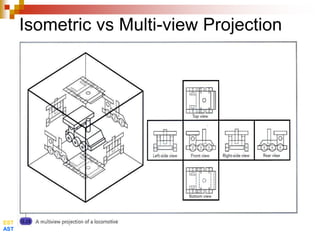

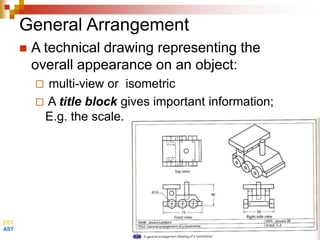

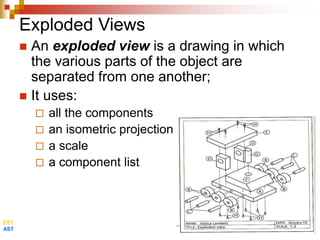

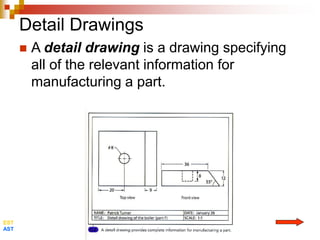

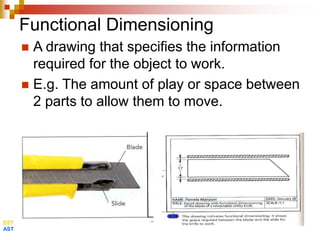

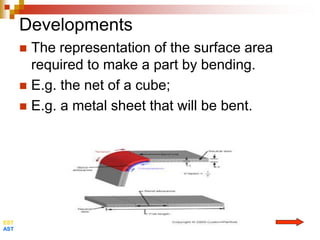

- Technical drawings including projections, general arrangements, exploded views, details, dimensions, and developments.

- Manufacturing processes involving measuring, layout, machining, assembling, and finishing.