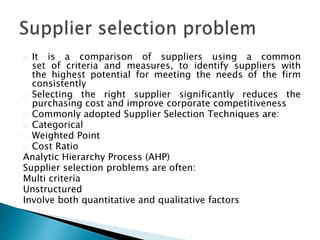

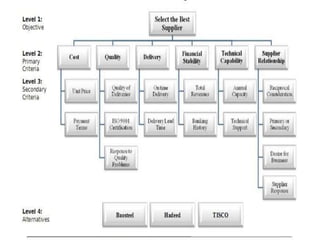

AHP is a multi-criteria decision making method developed in the 1970s to solve complex decision problems. It breaks problems down into a hierarchy with criteria and alternatives, then uses pairwise comparisons to determine priorities. AHP can handle both quantitative and qualitative factors, and subjective judgments. It has been used by companies like Xerox, IBM, and Ford for supplier selection, which is important for controlling costs. AHP models supplier selection with criteria in a hierarchy, then evaluates suppliers on each criteria using techniques like pairwise comparisons to identify the best supplier match.