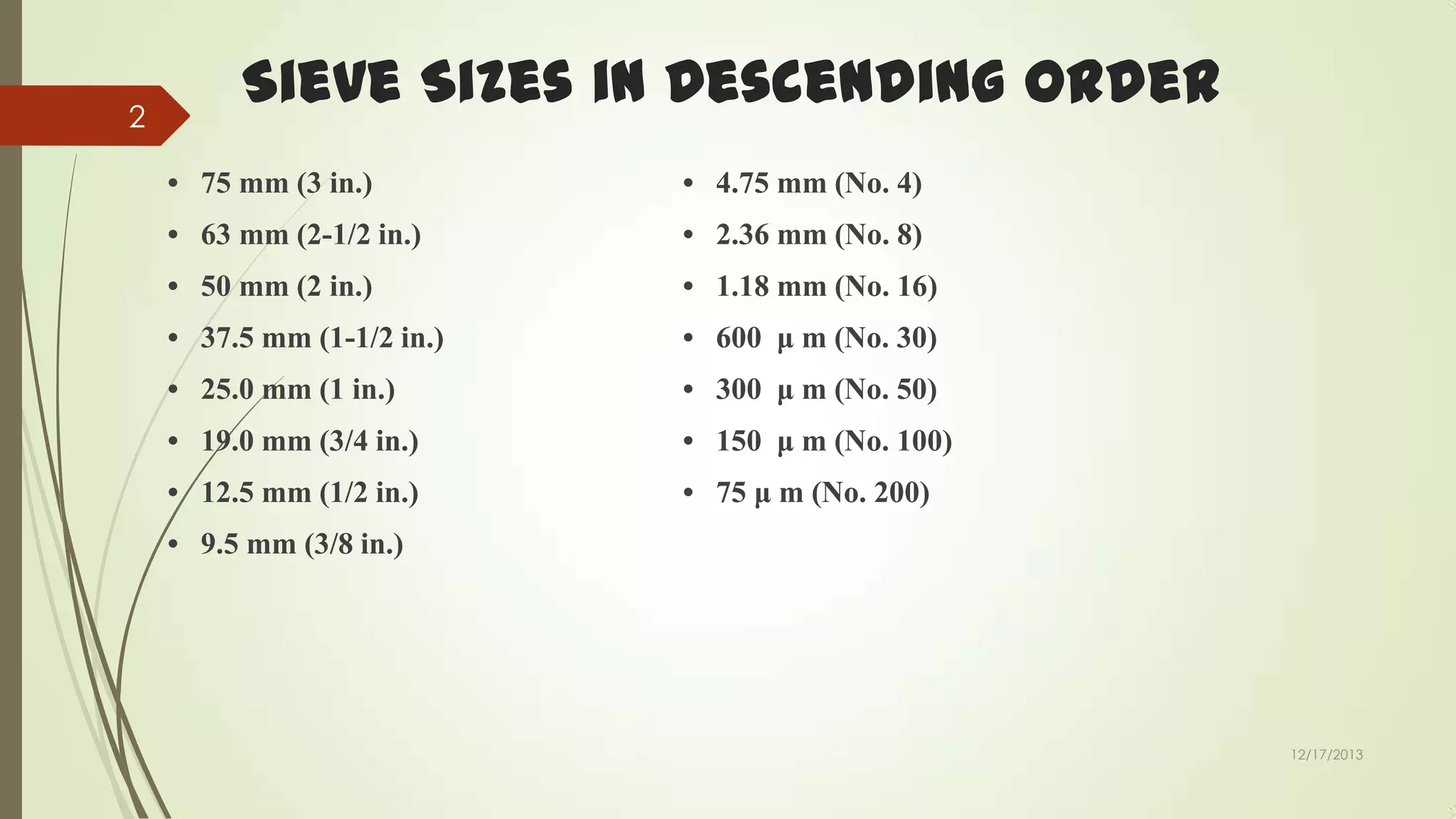

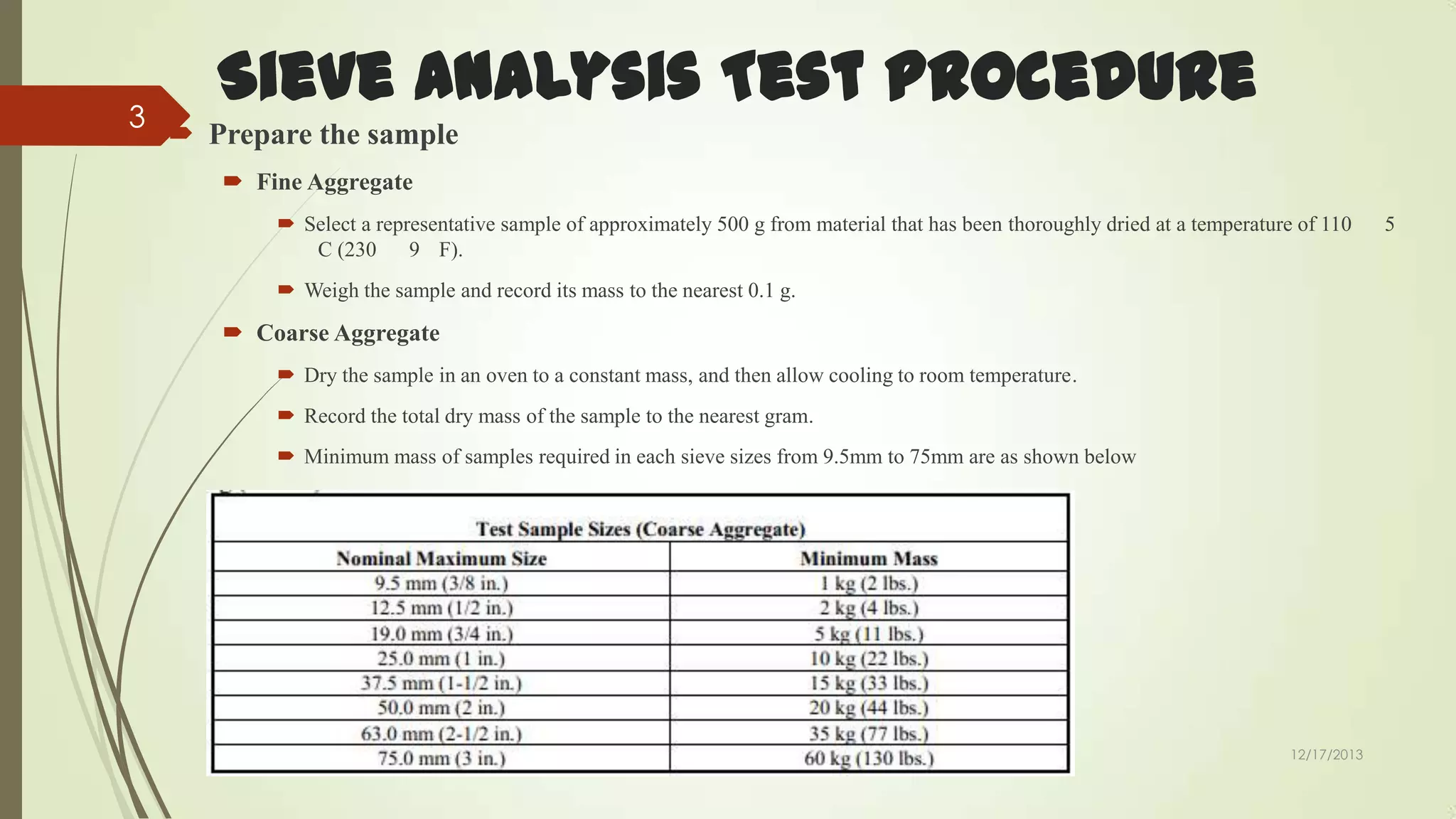

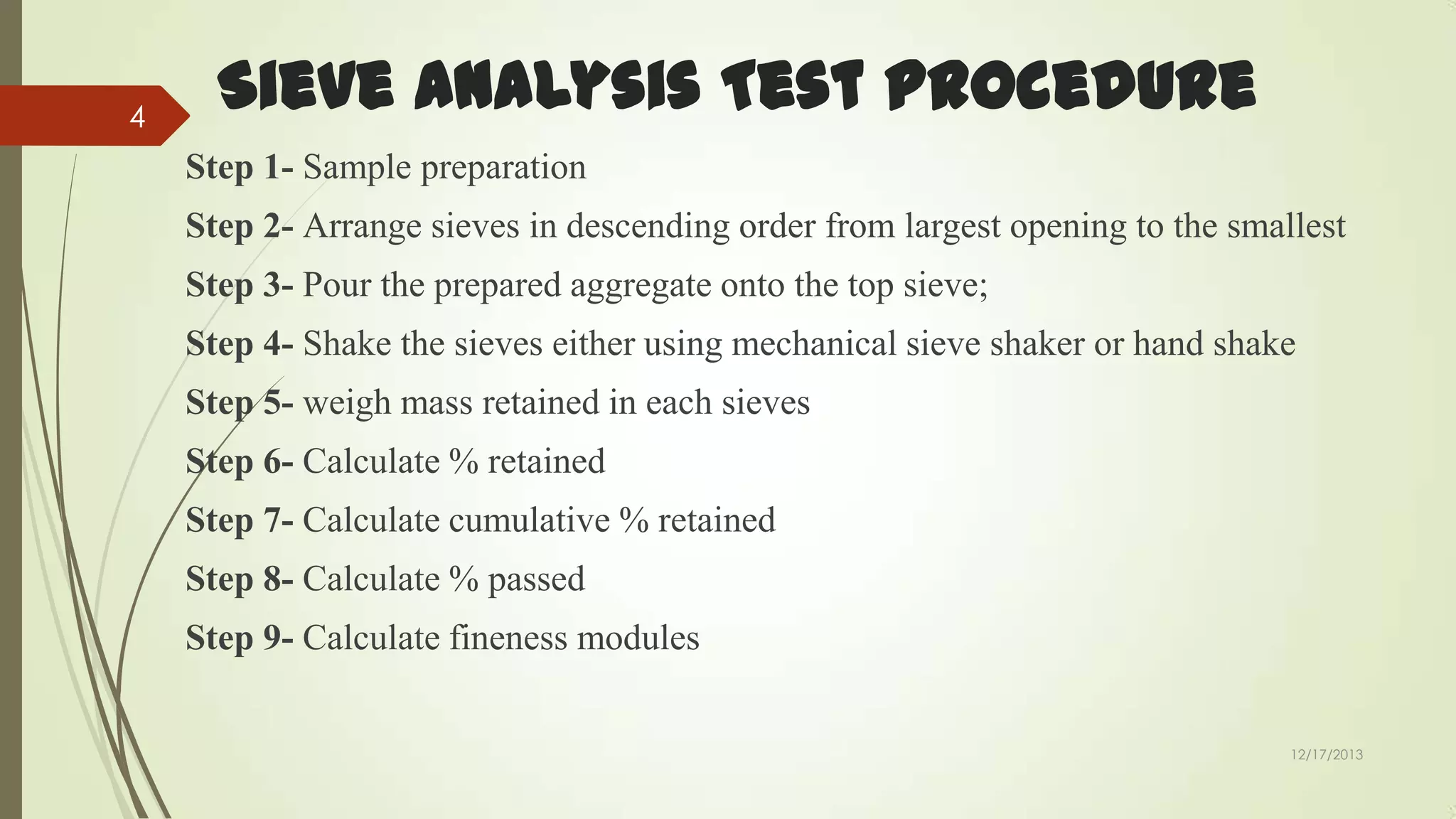

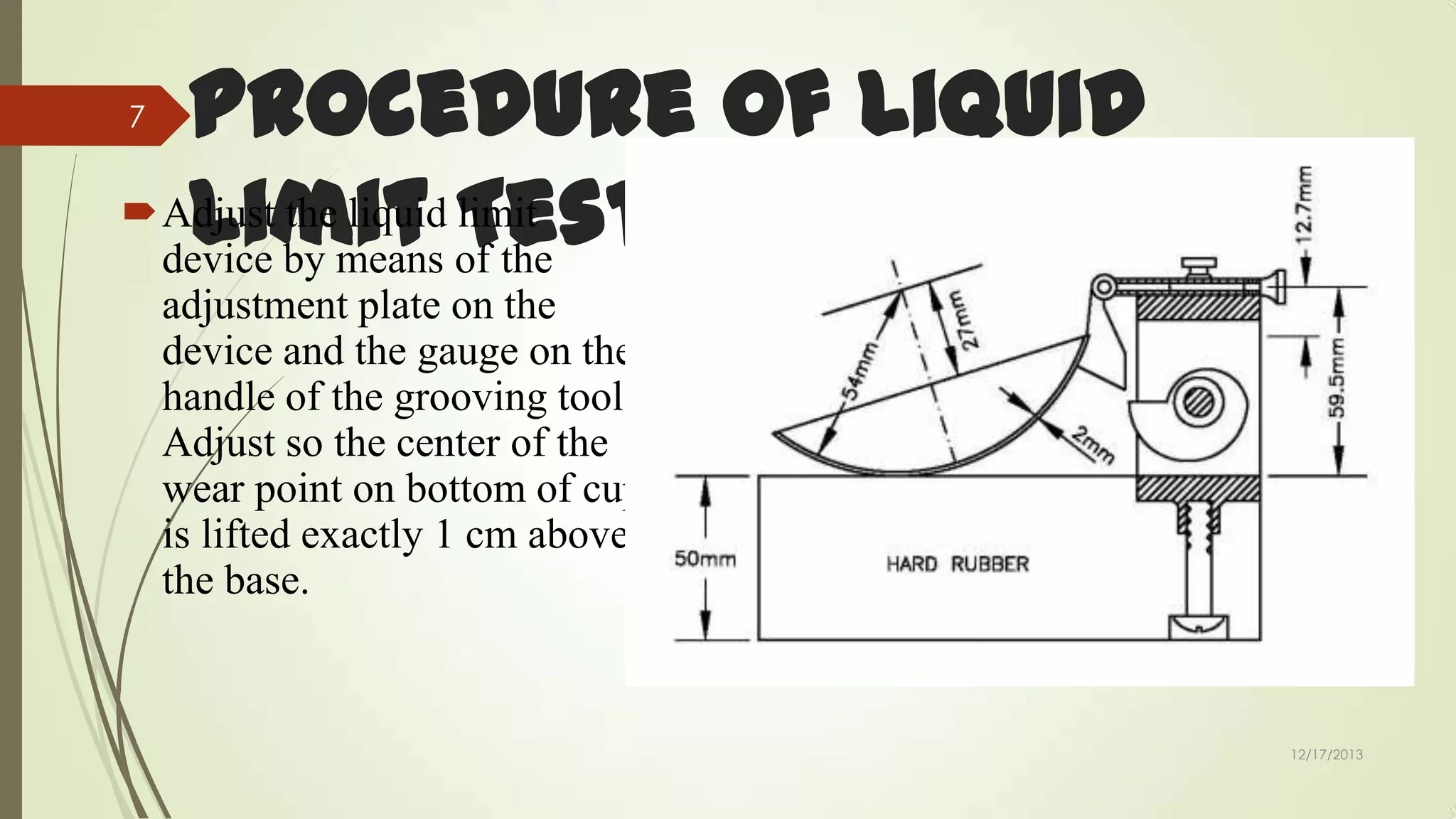

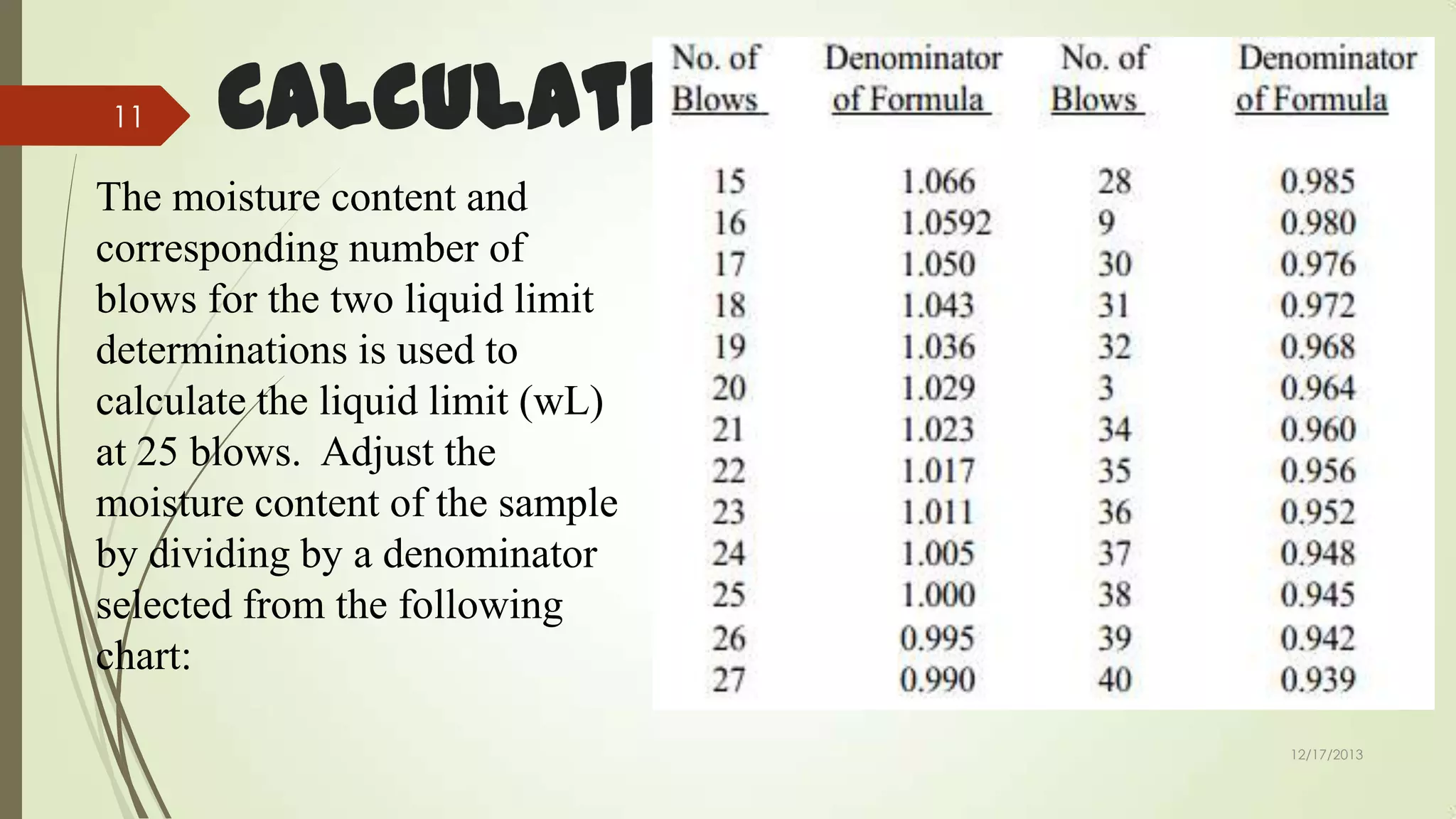

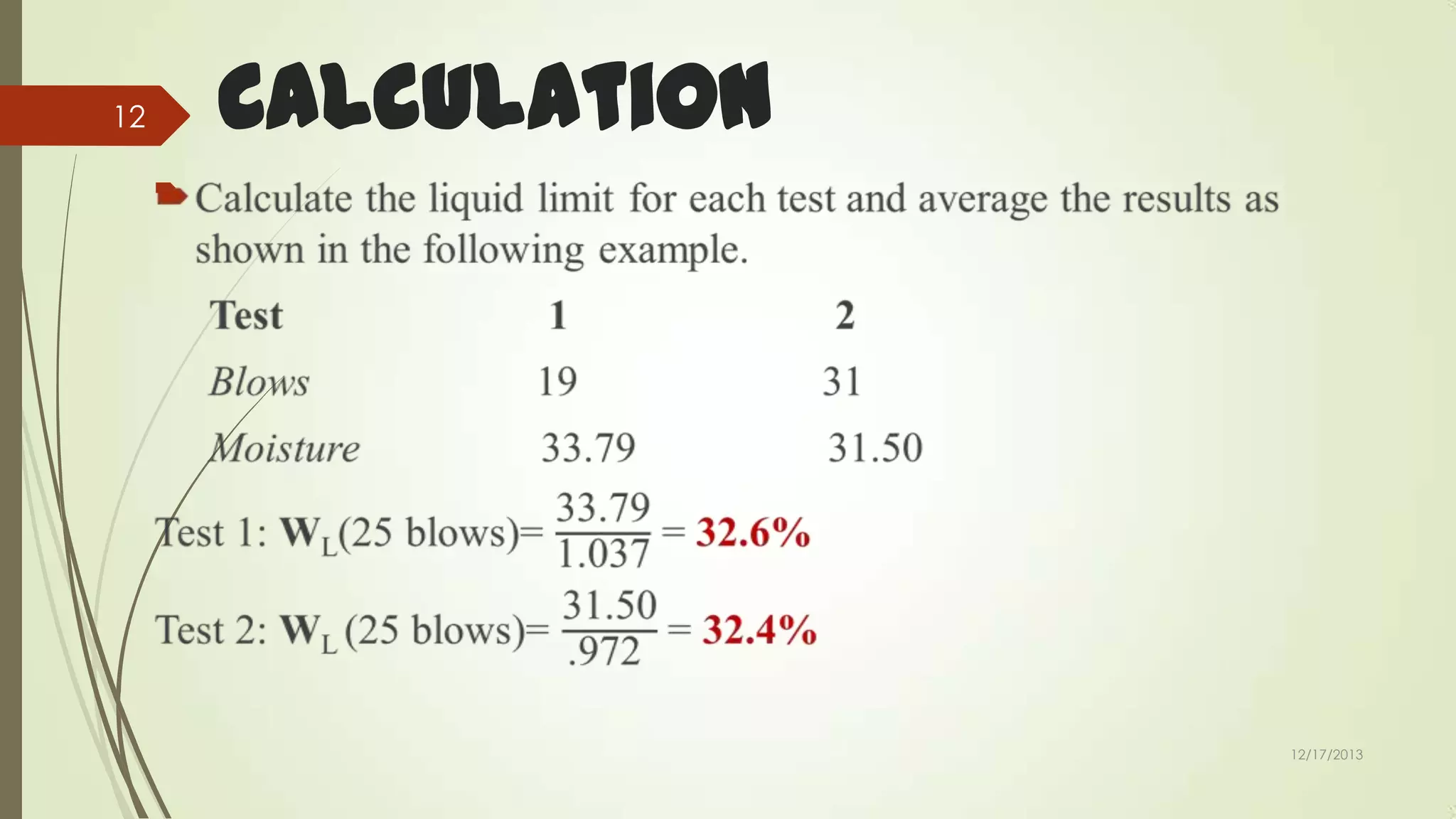

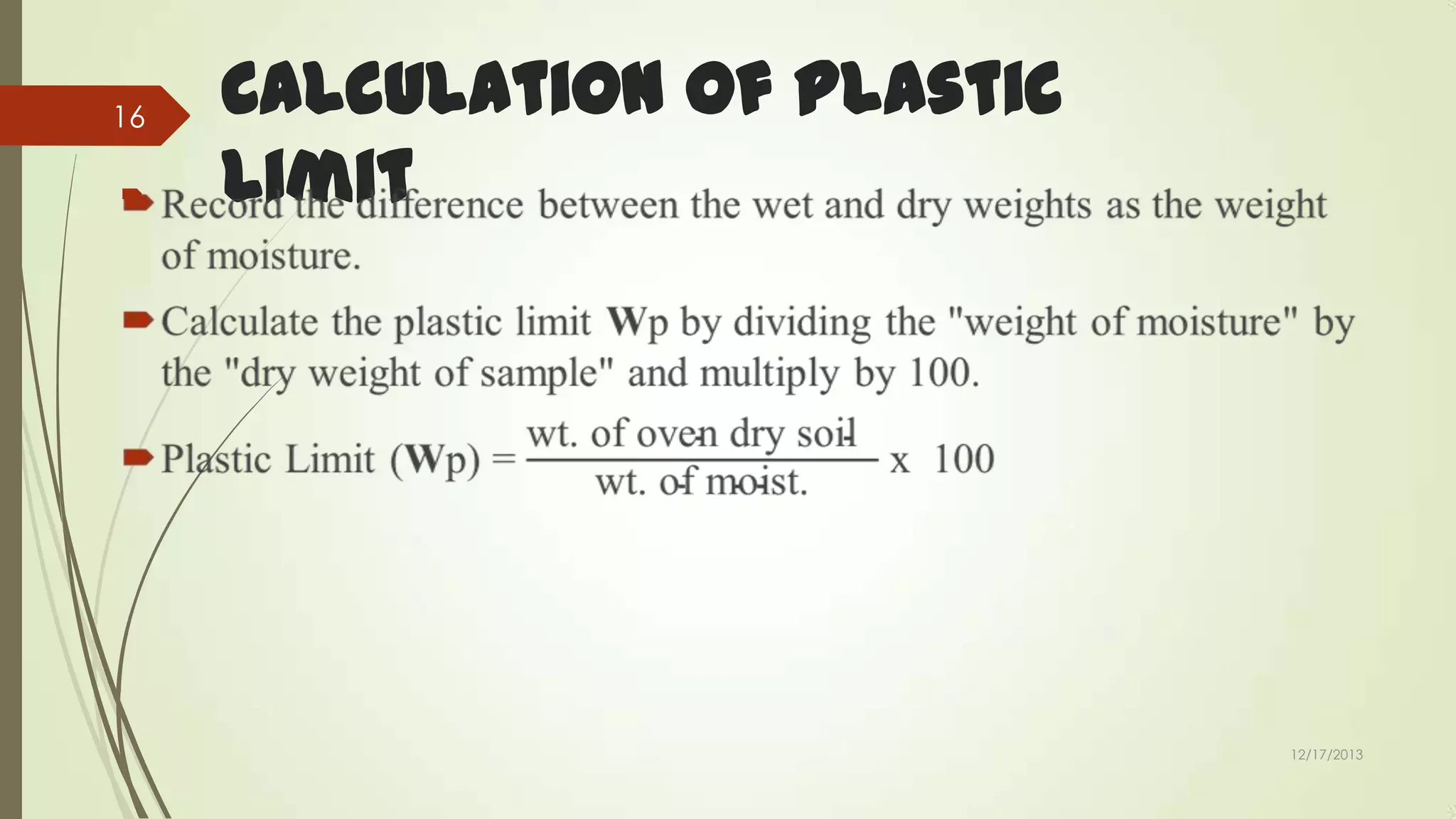

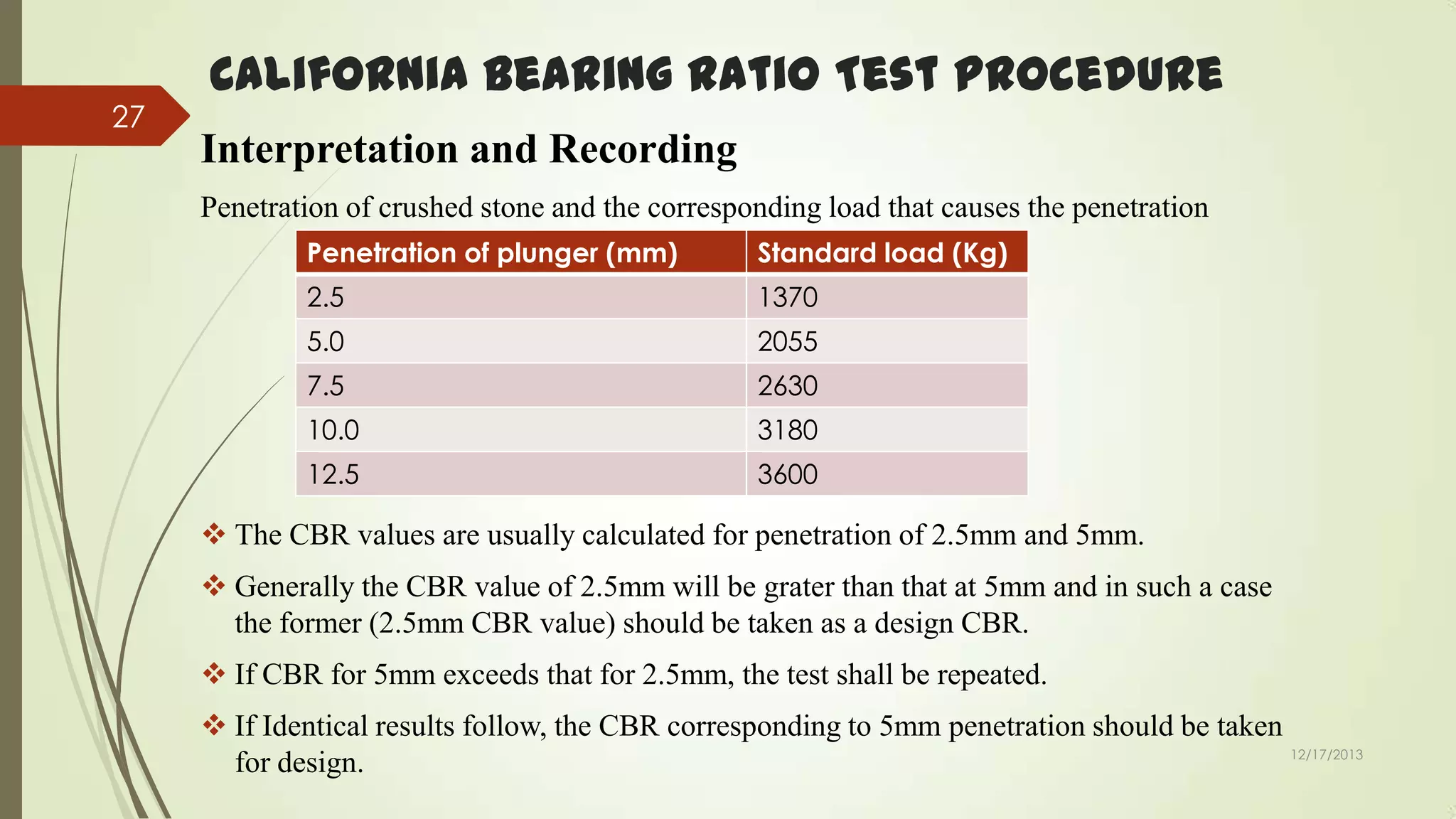

This document outlines various soil testing procedures including sieve analysis, Atterberg limits, compaction tests, and California Bearing Ratio (CBR) tests. It details the methods for preparing samples, conducting tests, and calculating results, with specific focus on moisture content and density assessments. Each test procedure is structured step-by-step to ensure consistency and accuracy in determining soil properties.