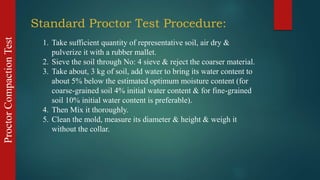

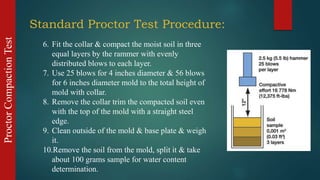

The document describes the standard Proctor compaction test procedure. The test is used to determine the maximum dry density and optimum moisture content of soils. It involves compacting soil samples at incrementally increased moisture contents using a specified compaction method. A compaction curve is plotted showing the relationship between dry density and moisture content. The peak of the curve indicates the optimum moisture content and maximum dry density achieved for that soil. The test uses a cylindrical metal mold, rammer, balance, oven and other equipment to compact and analyze the soil samples according to steps that sieve, mix, compact and weigh the soil at different moistures.