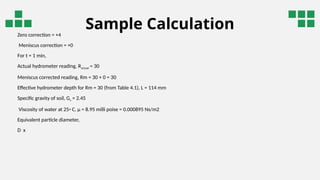

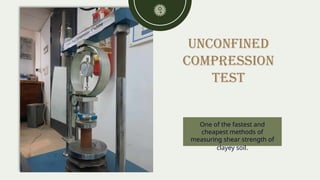

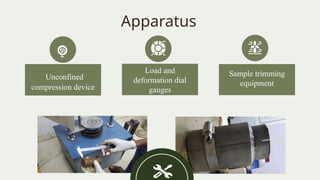

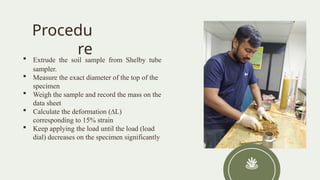

The document outlines various laboratory experiments in geotechnical engineering, focusing on soil property assessment through both visual inspection and standard testing methods. The objectives include determining soil properties such as specific gravity, liquid limit, plastic limit, and conducting unconfined compression tests. Detailed procedures and data tables for sample collection and analysis are provided to facilitate accurate soil classification and evaluation.