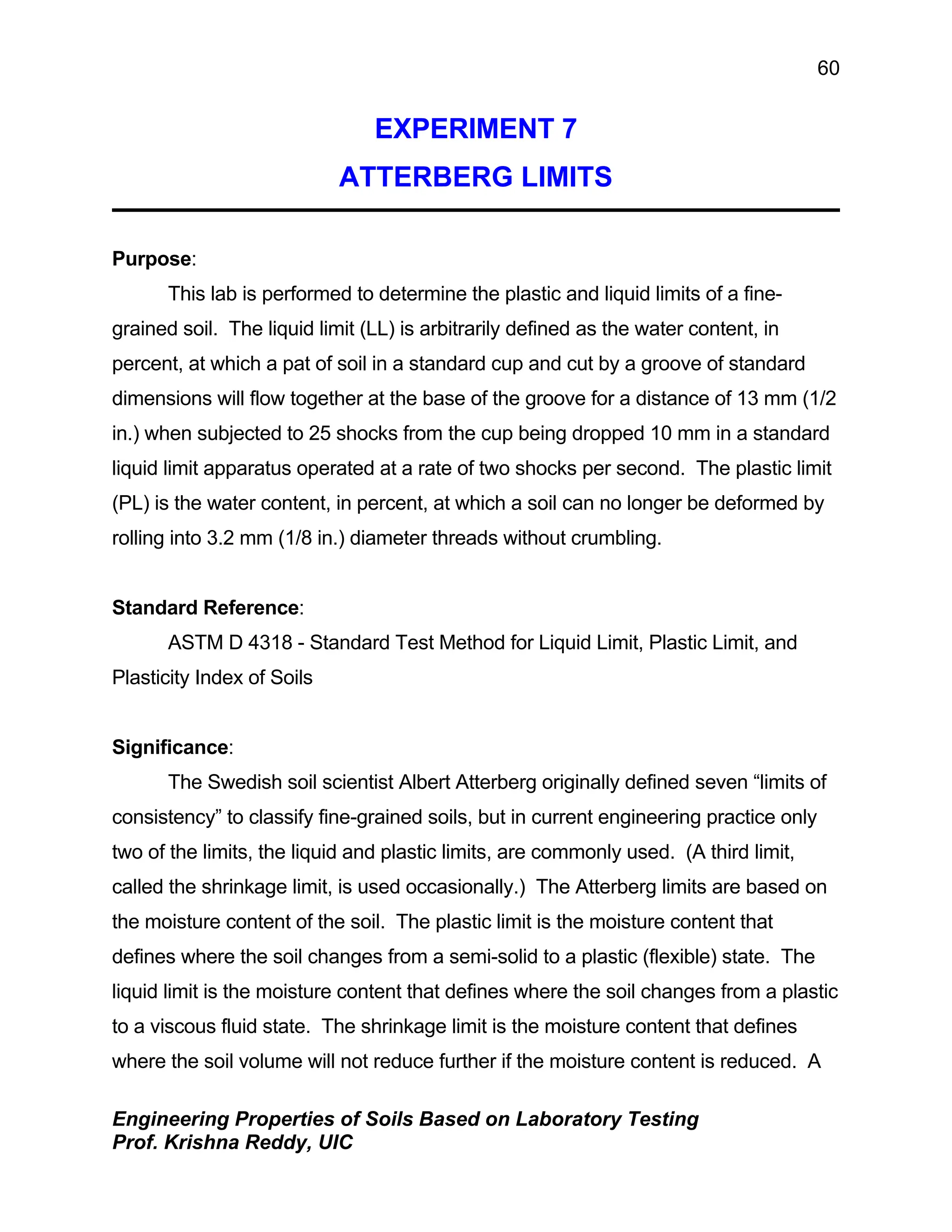

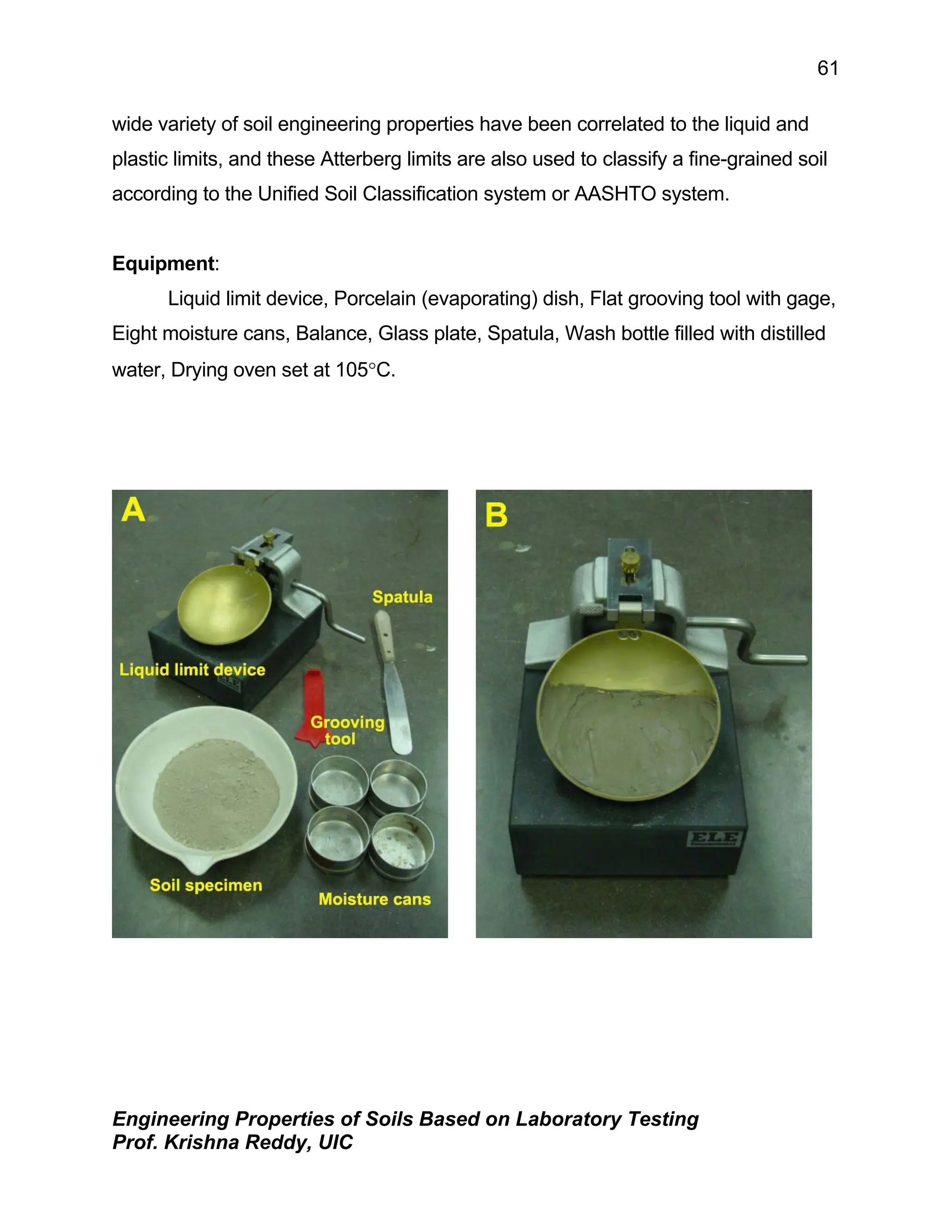

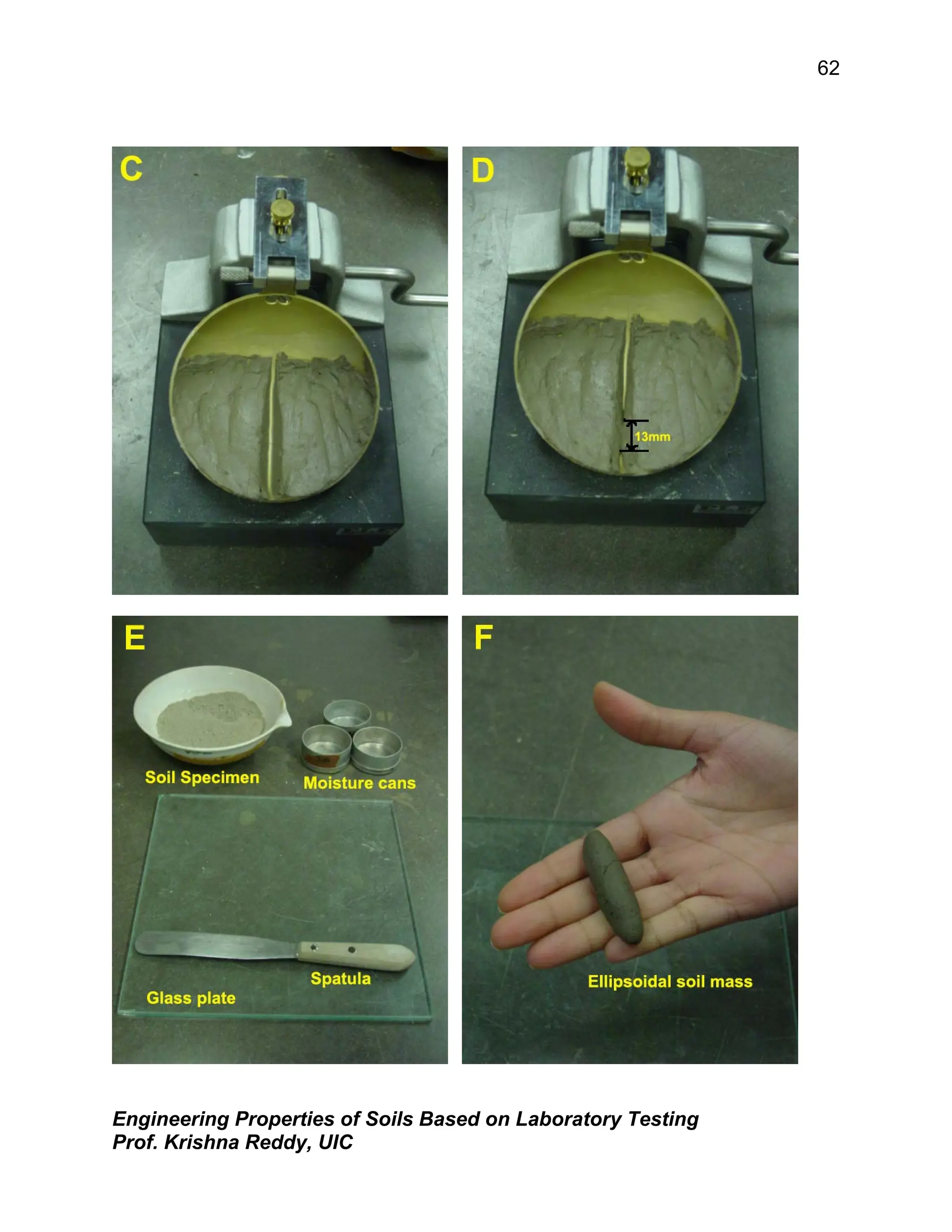

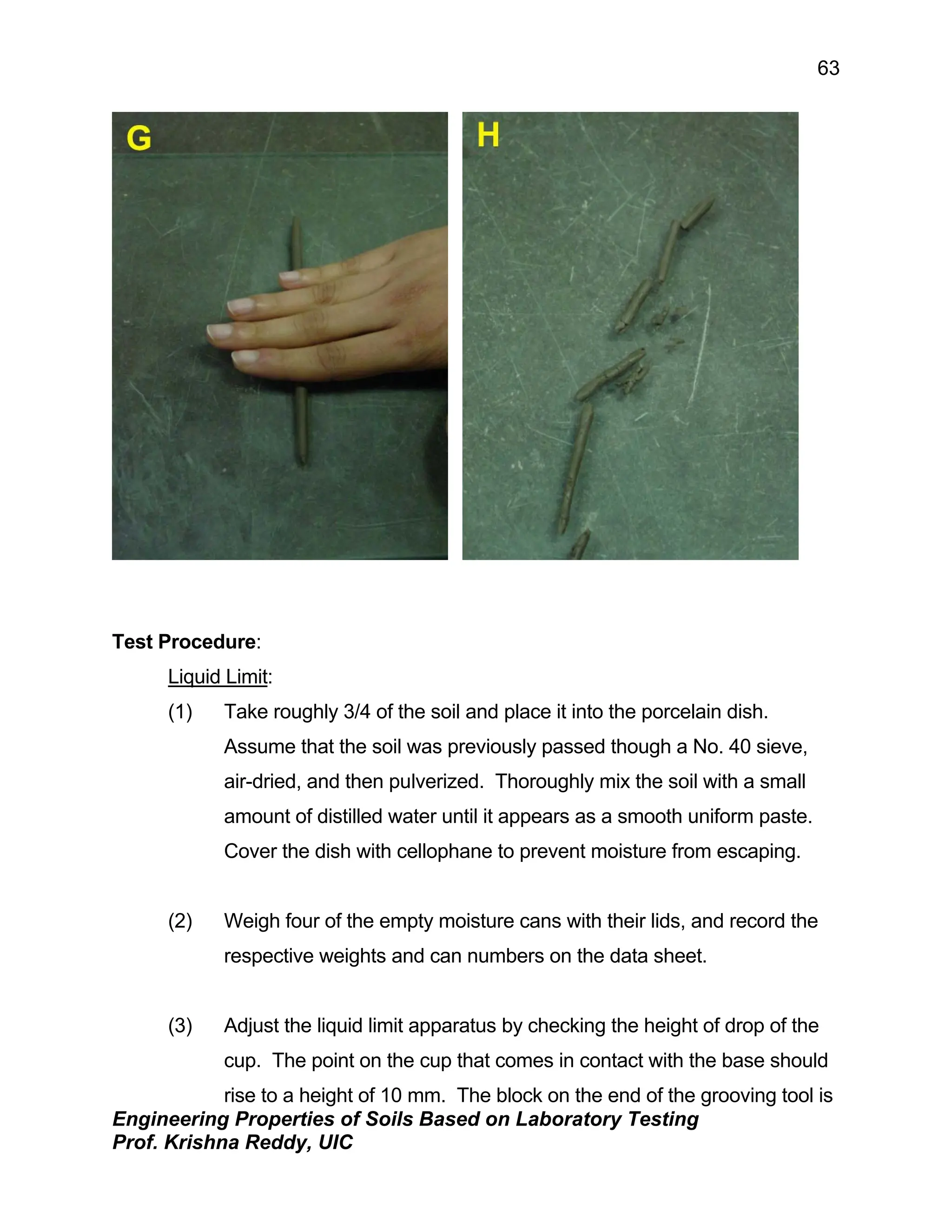

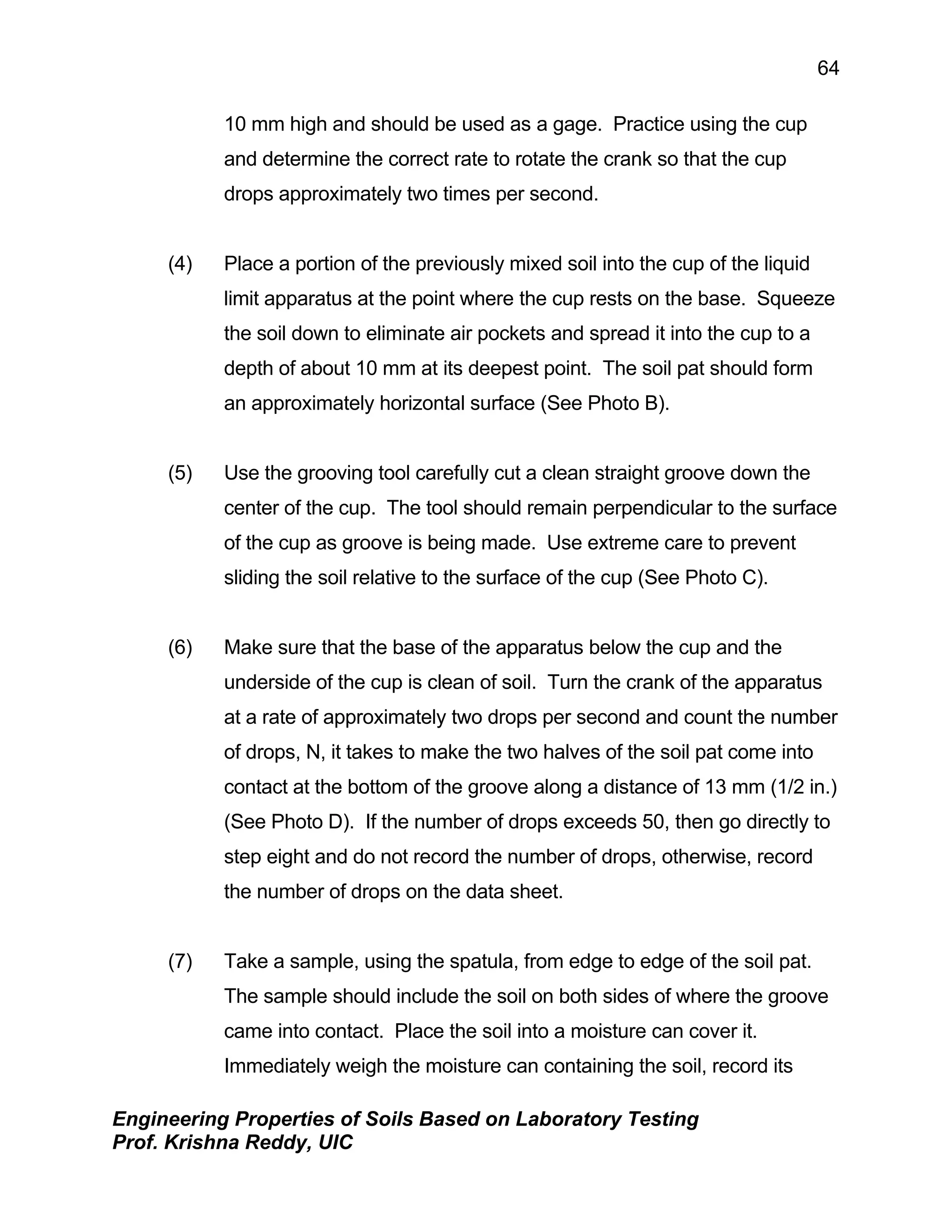

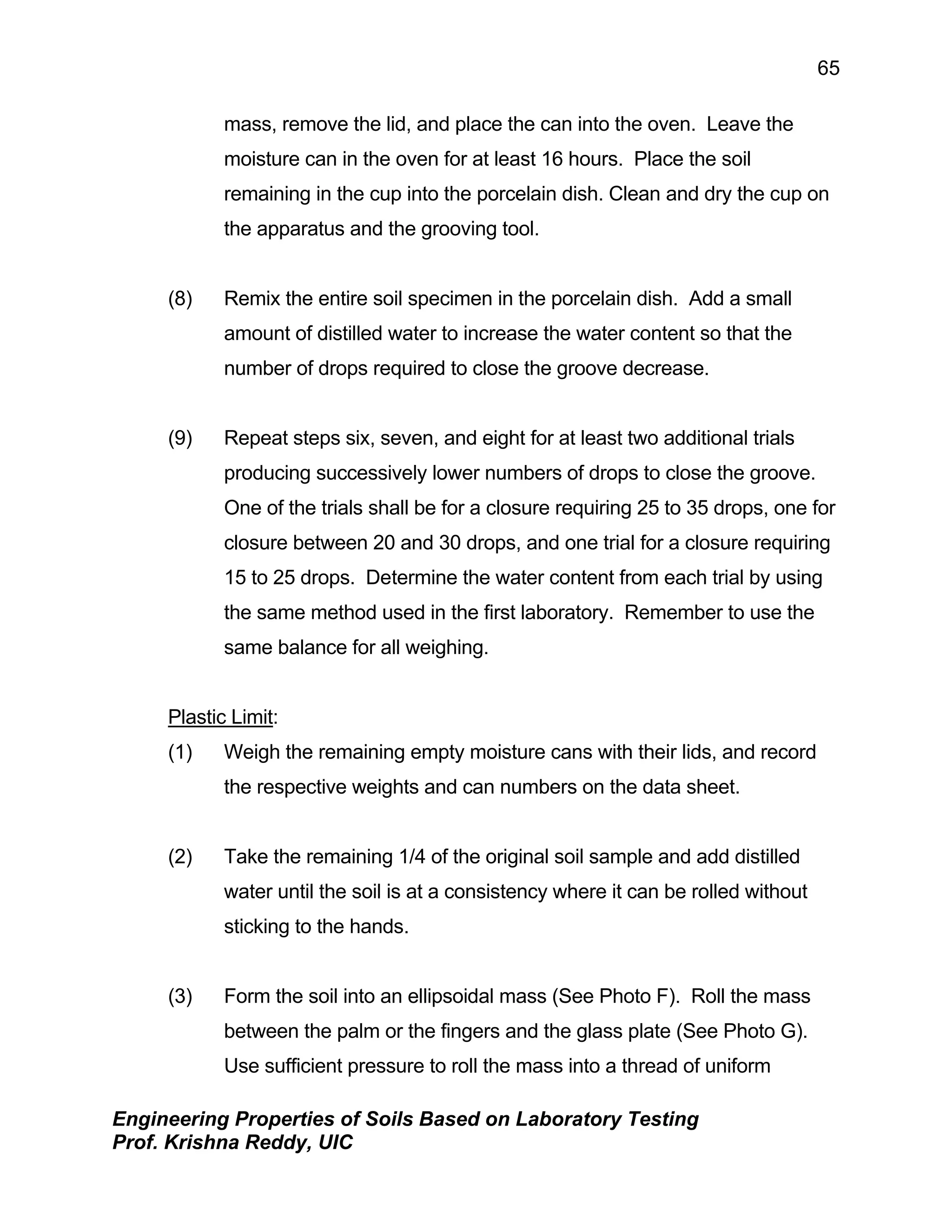

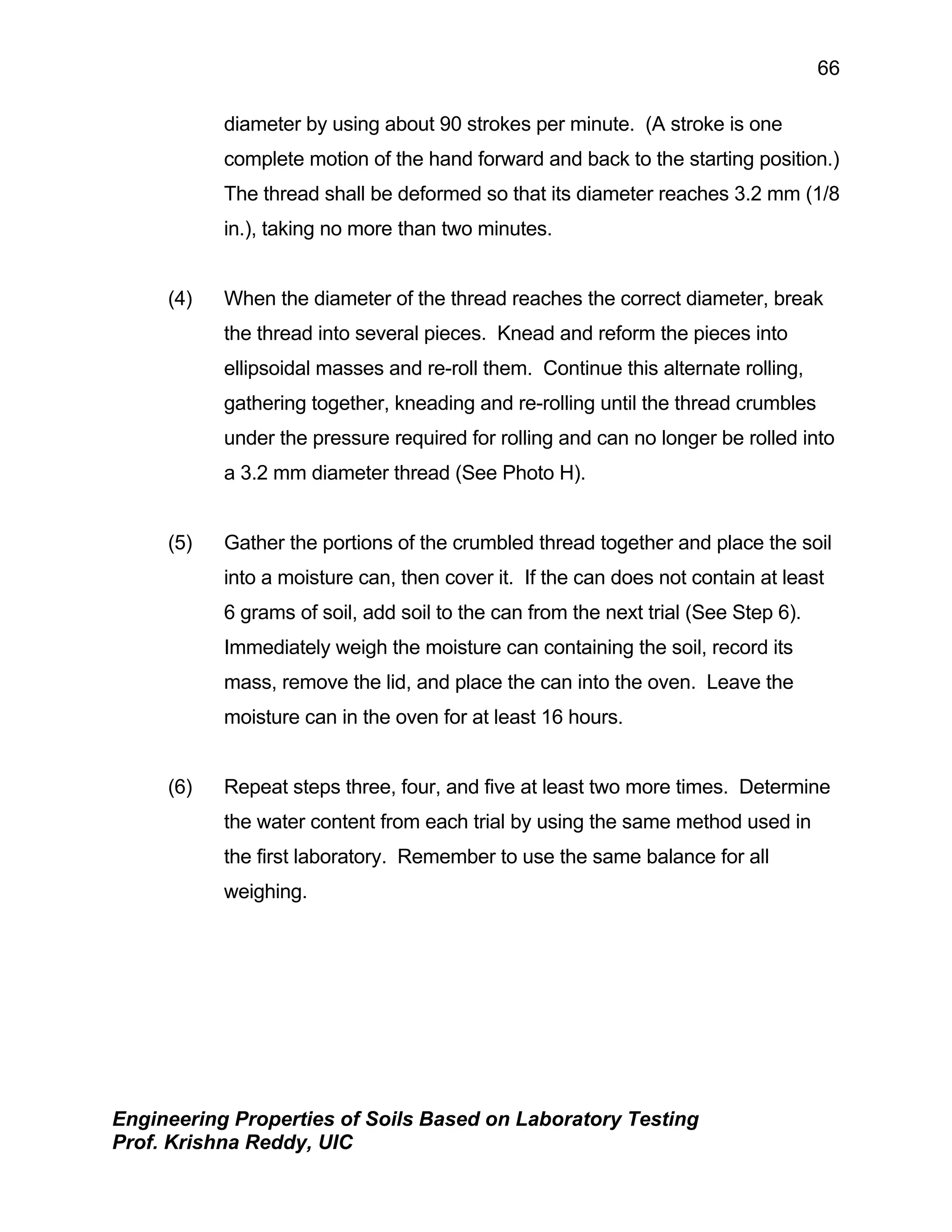

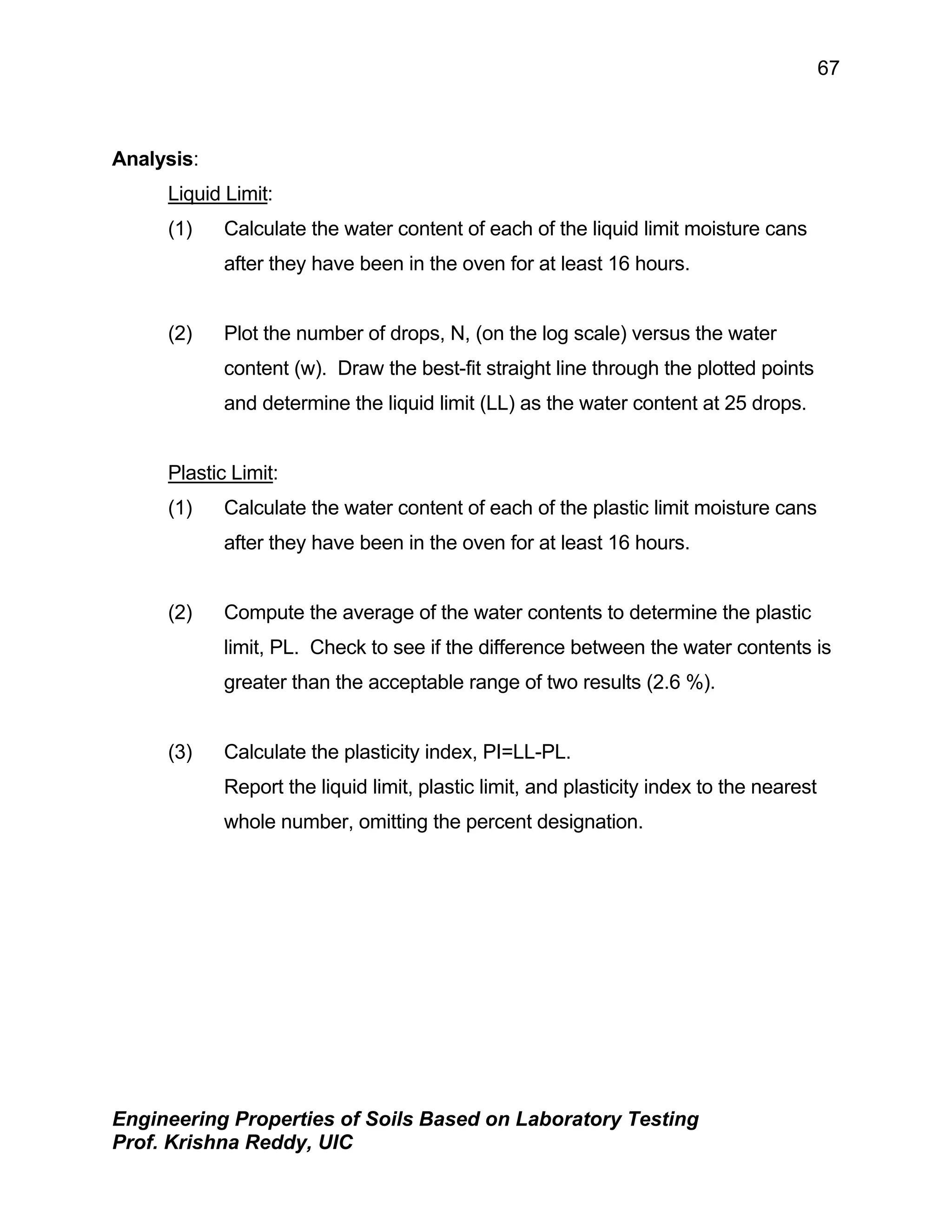

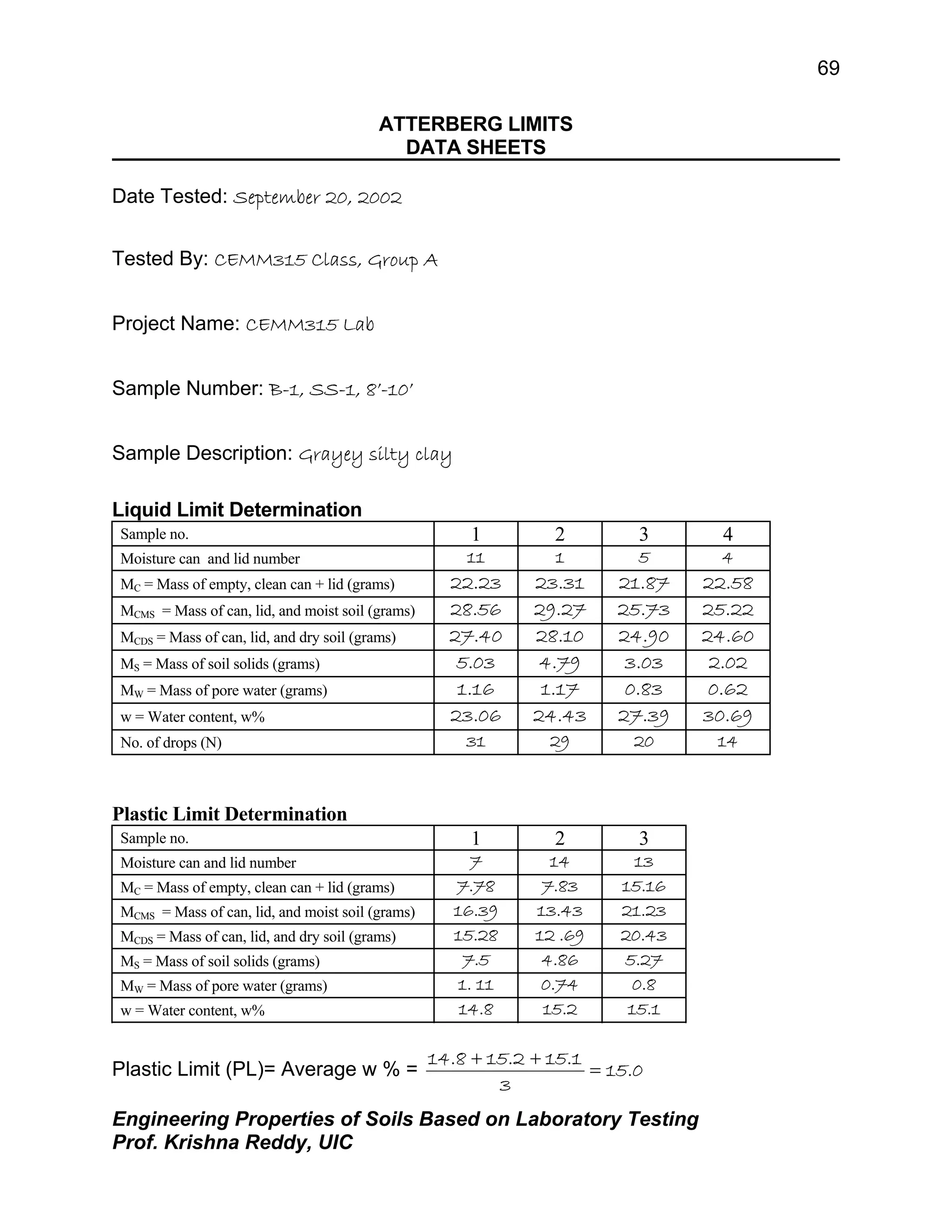

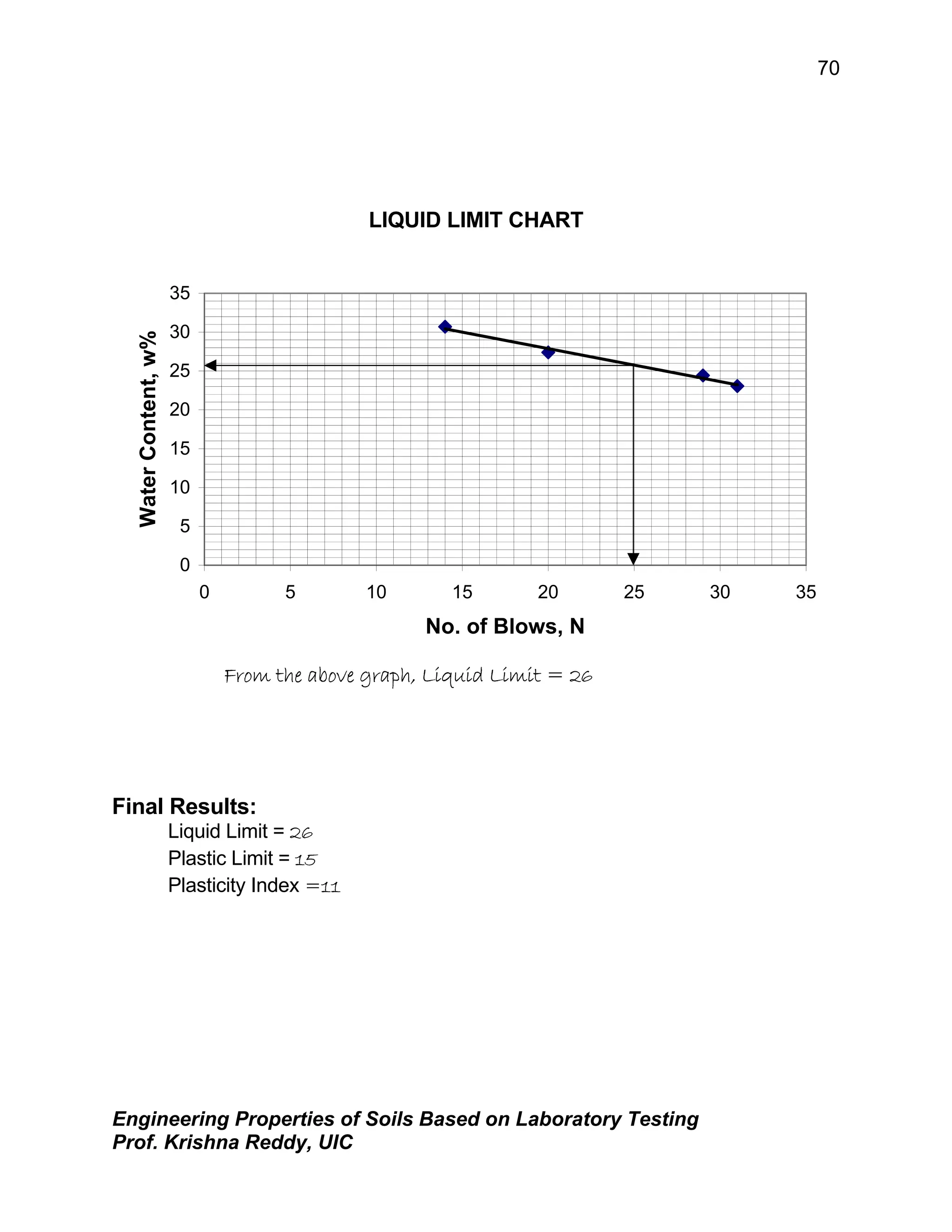

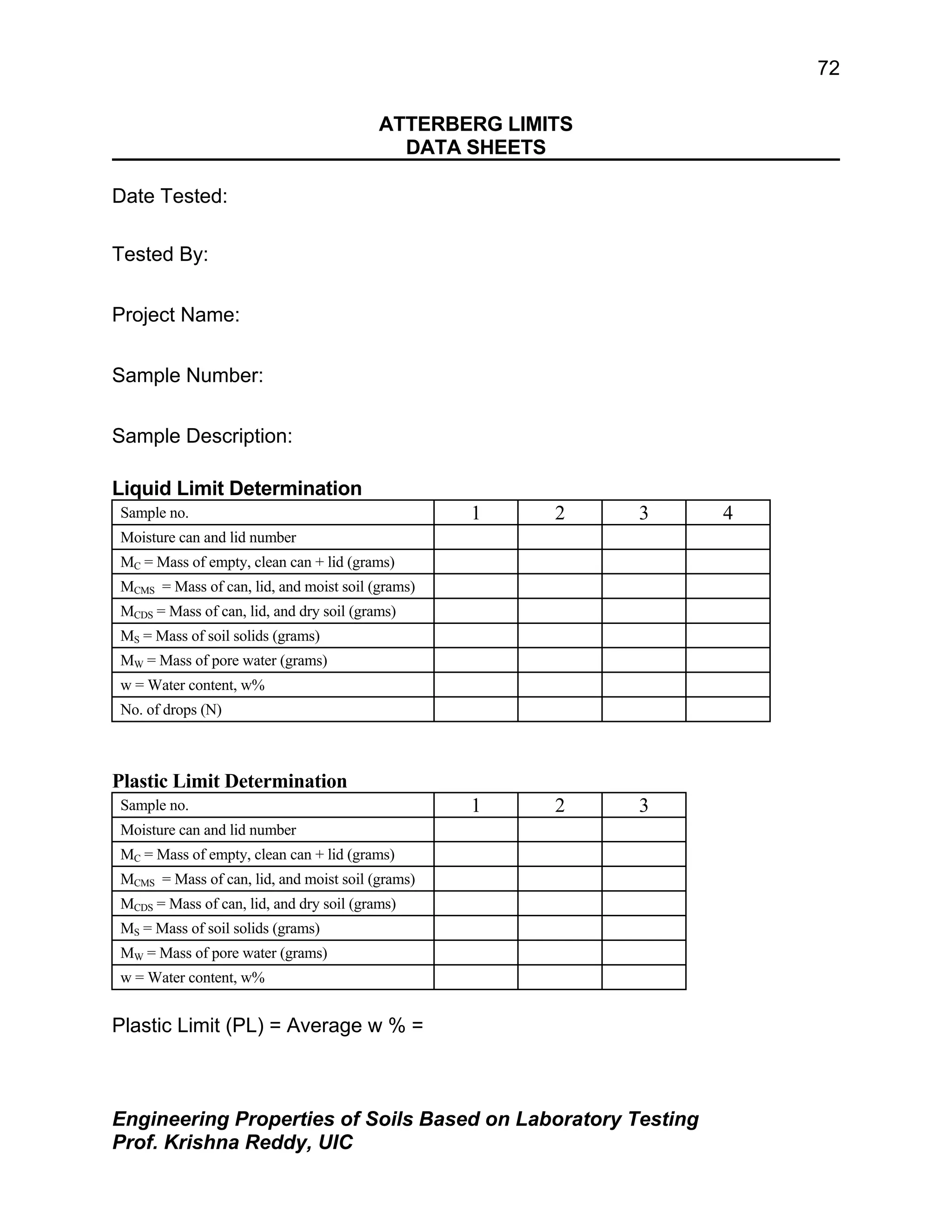

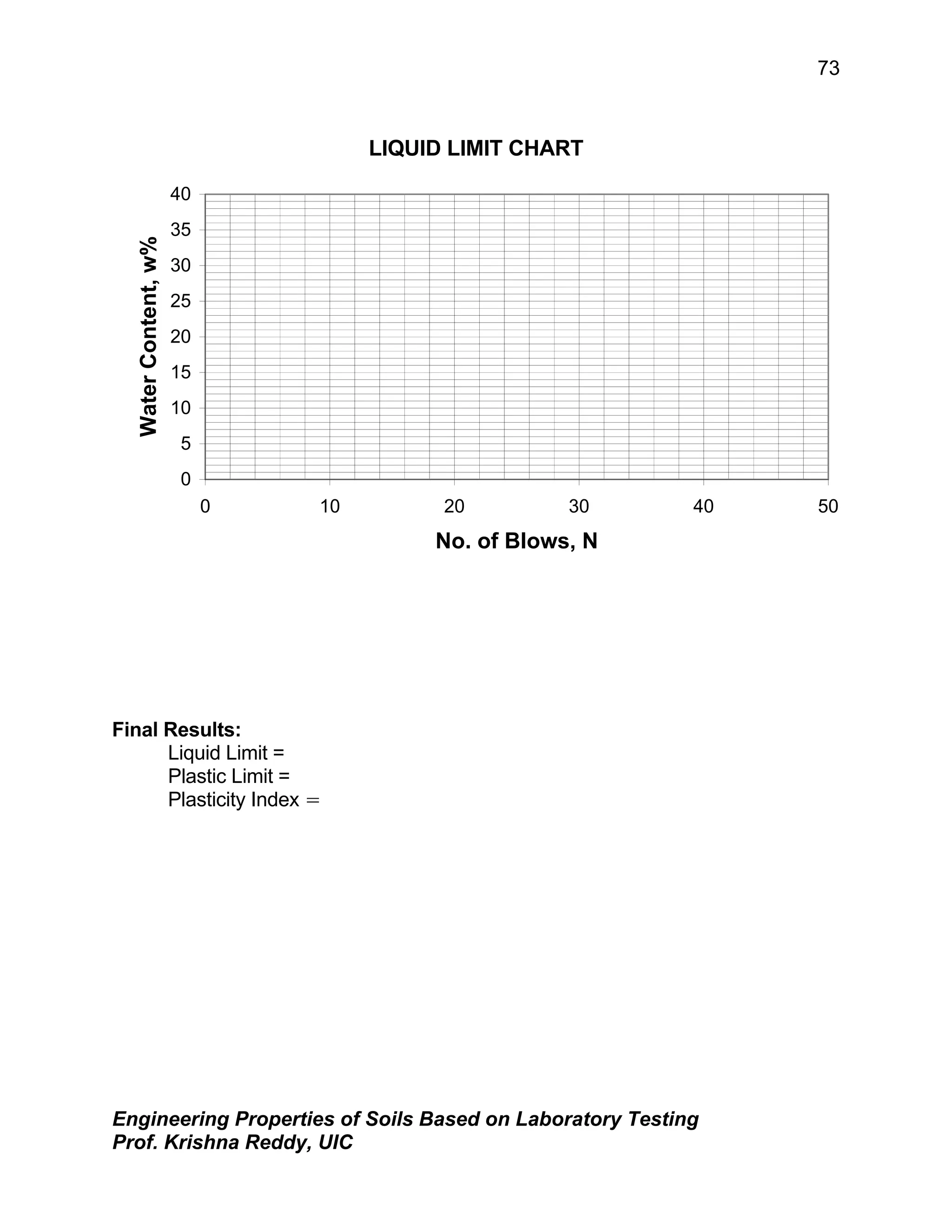

This document describes a laboratory test procedure to determine the Atterberg limits of a fine-grained soil, which are used to classify soils. The test involves measuring the moisture content at which the soil transitions from a plastic to liquid state (liquid limit), and from a semi-solid to plastic state (plastic limit). Samples are tested at different moisture contents and the number of blows to close a groove are recorded to find the liquid limit. The plastic limit is found by rolling threads of soil at different moisture contents. The liquid limit, plastic limit, and plasticity index are calculated and used to classify the soil.