The document is a thesis presentation on harvesting energy from an electrostrictive polymer composite. It includes:

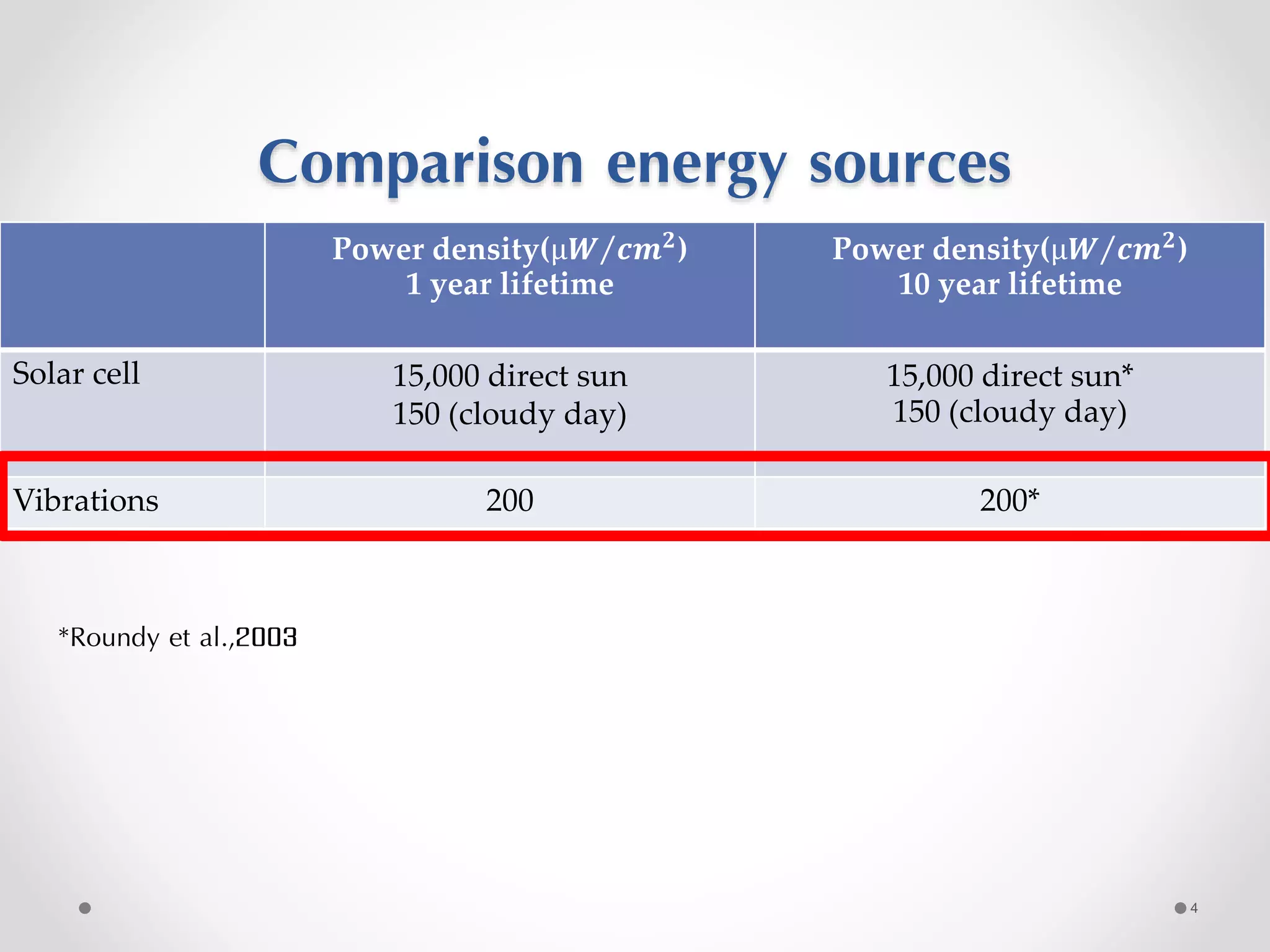

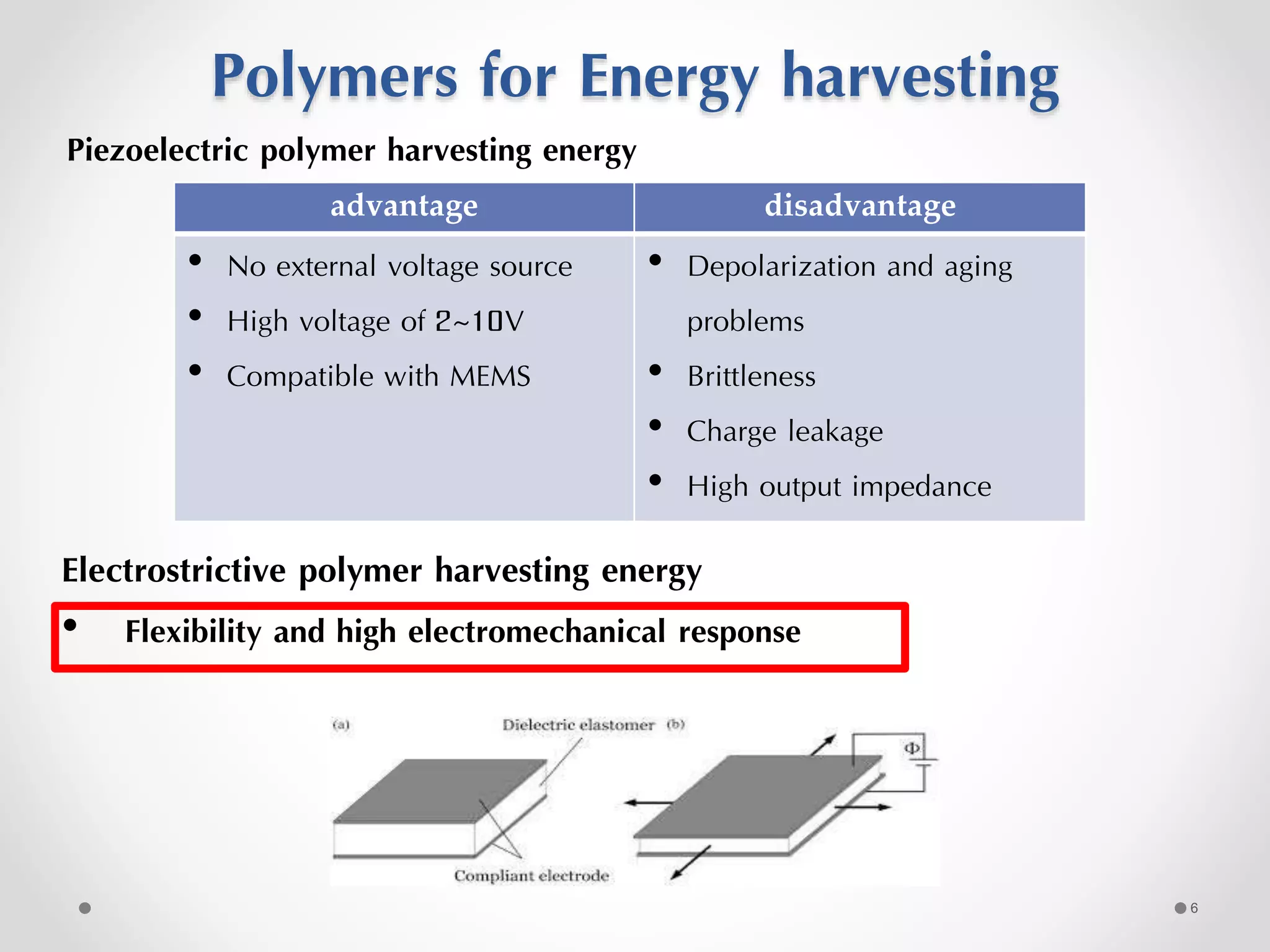

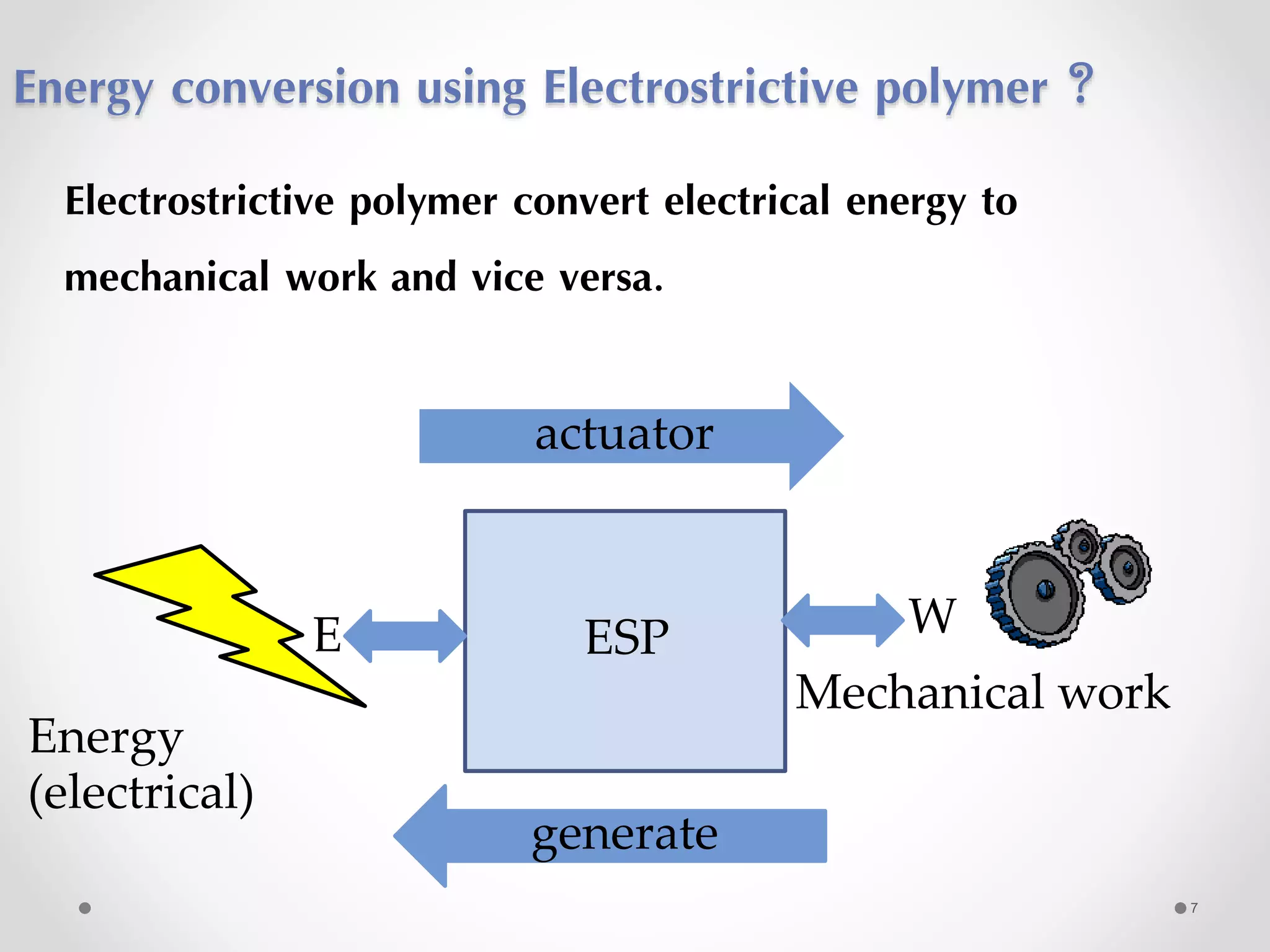

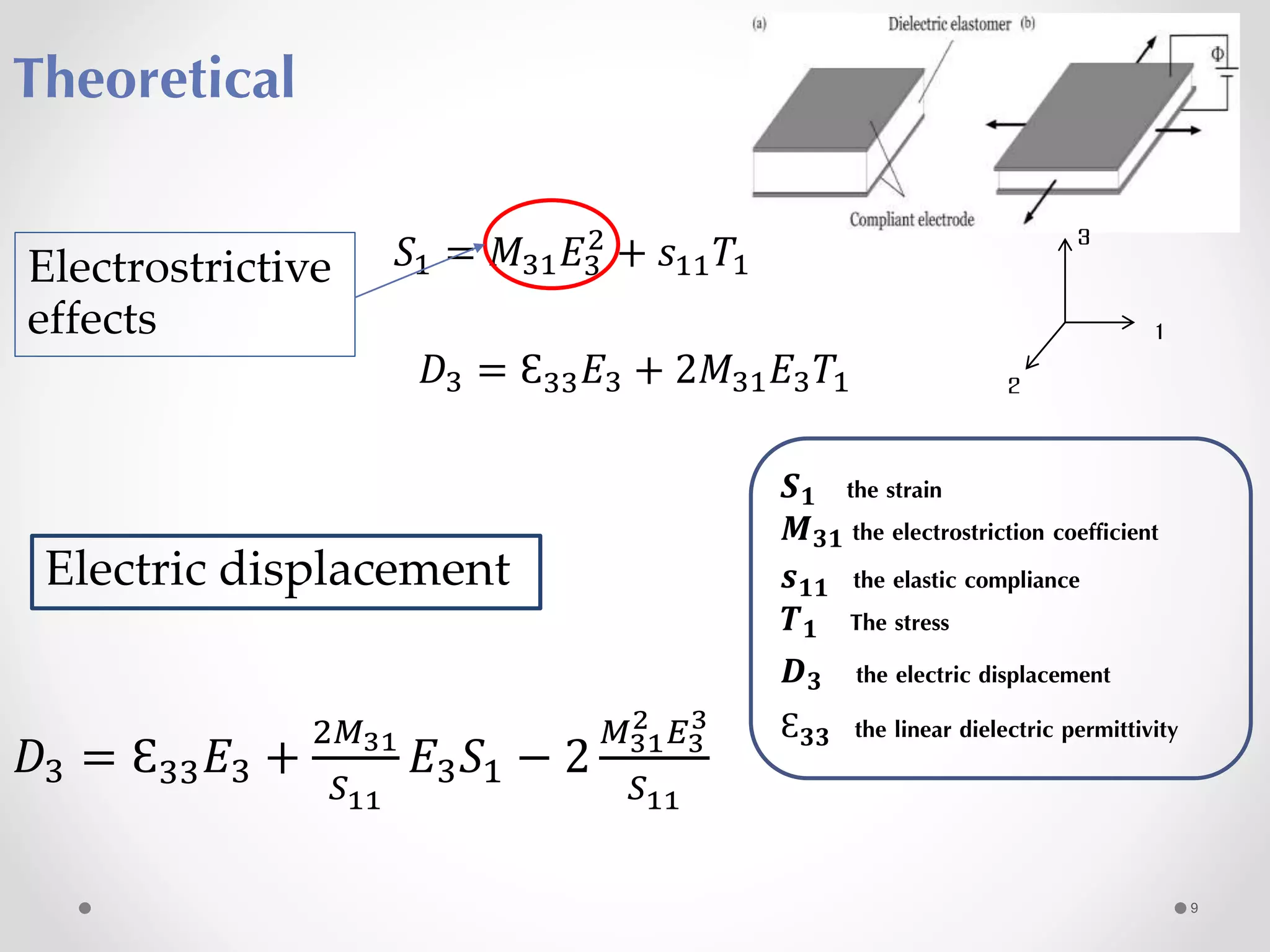

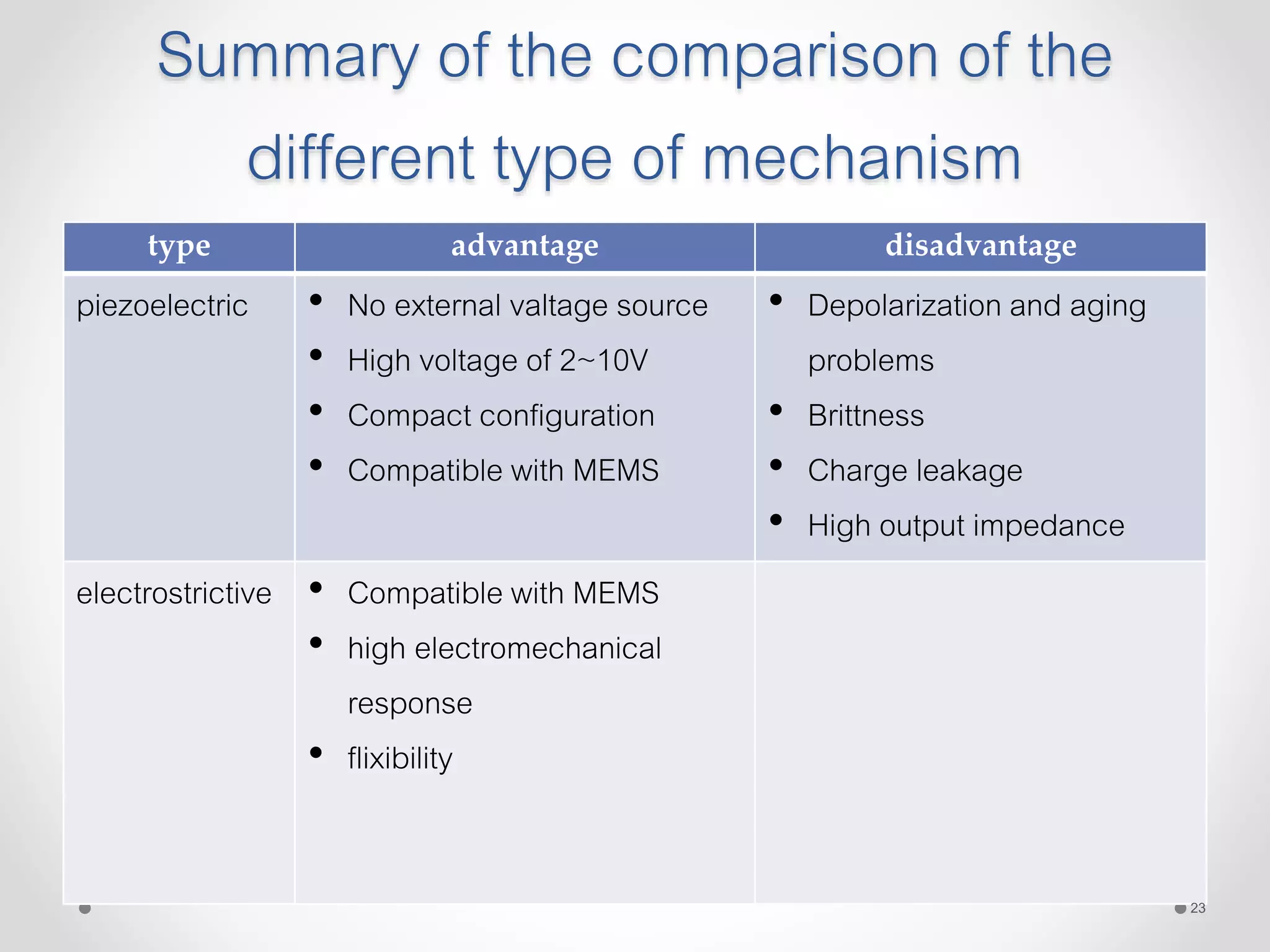

1) An introduction to energy harvesting and a comparison of energy sources. Vibration energy harvesting using smart materials like piezoelectric and electrostrictive polymers is discussed.

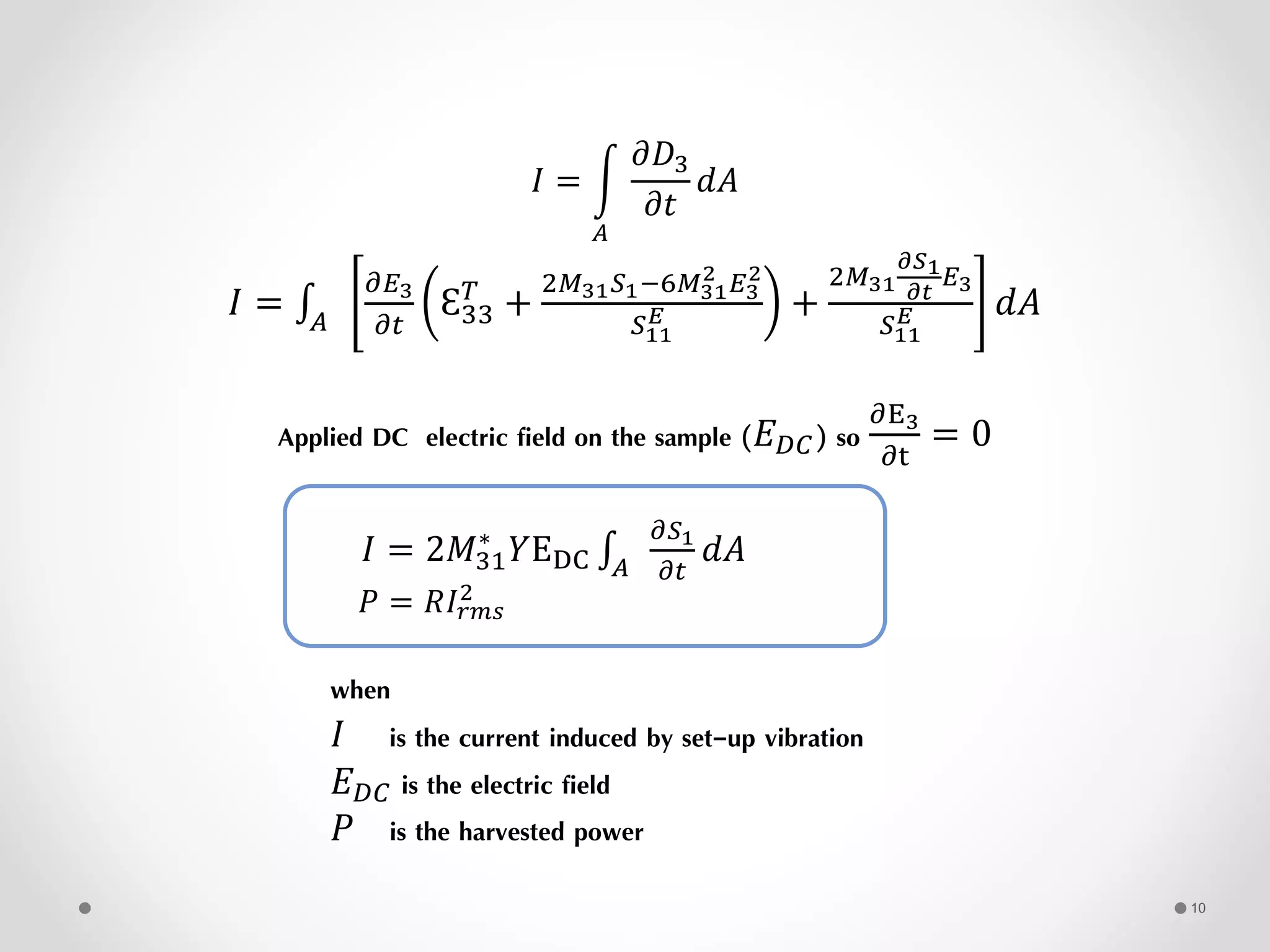

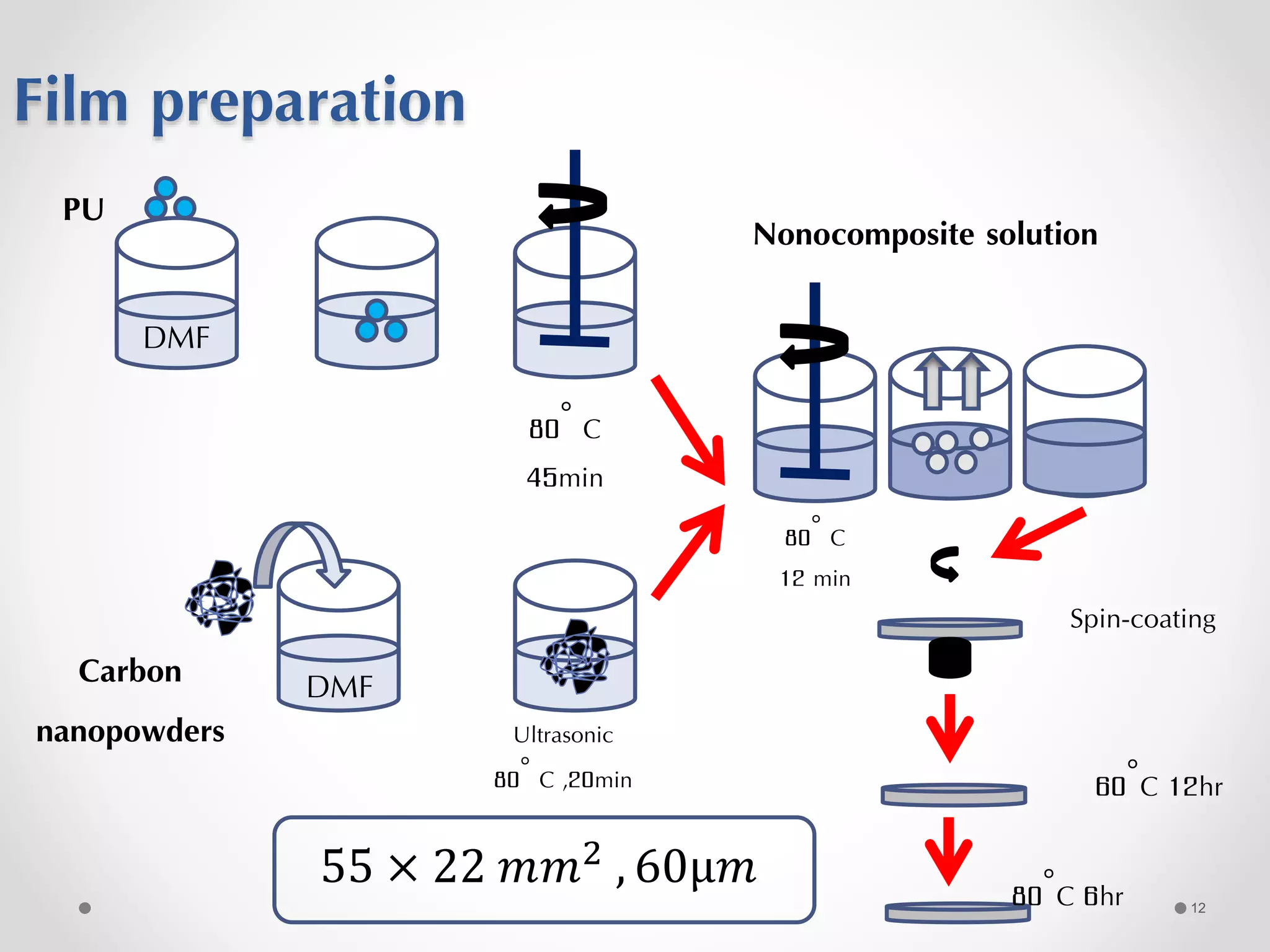

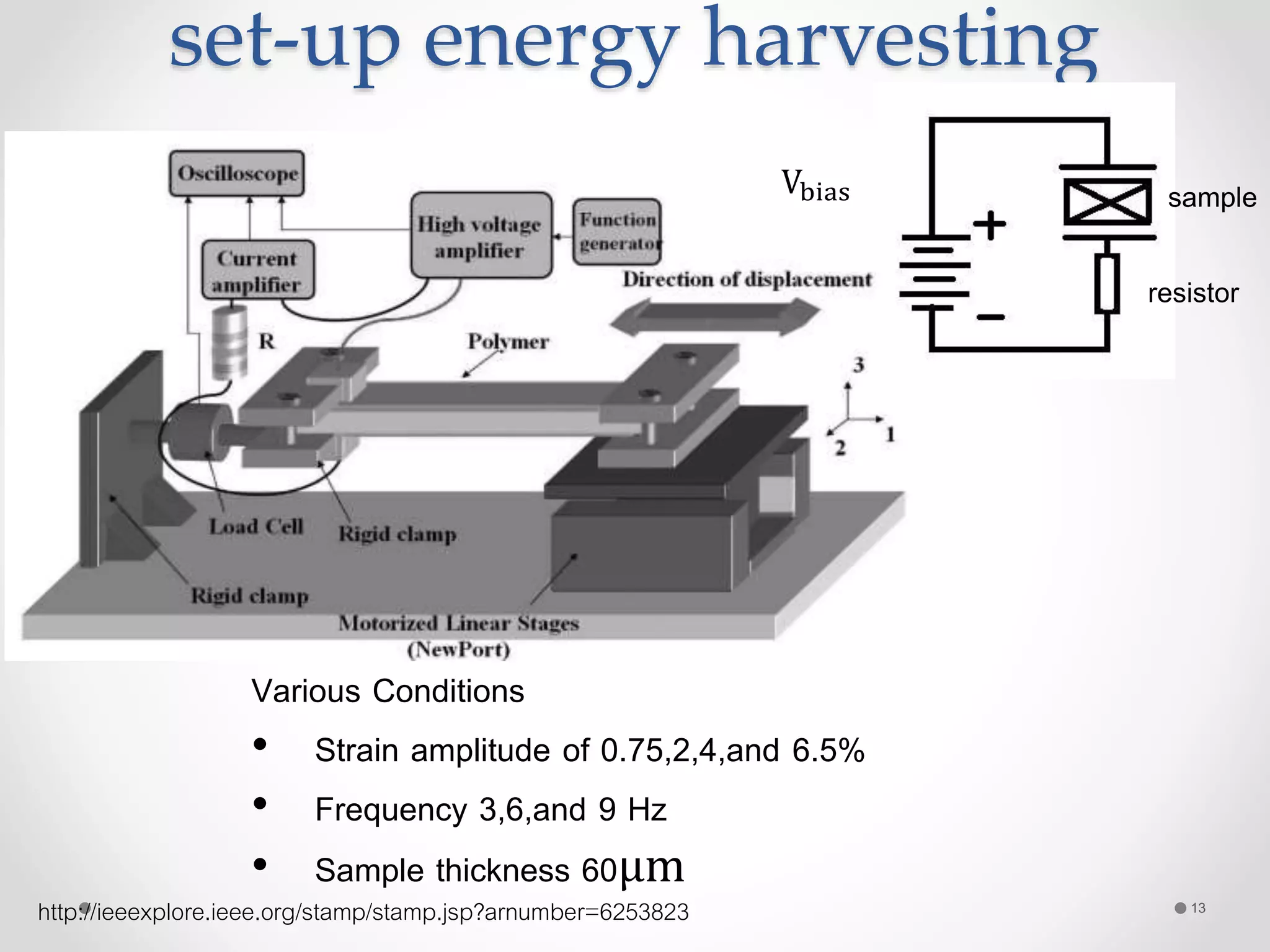

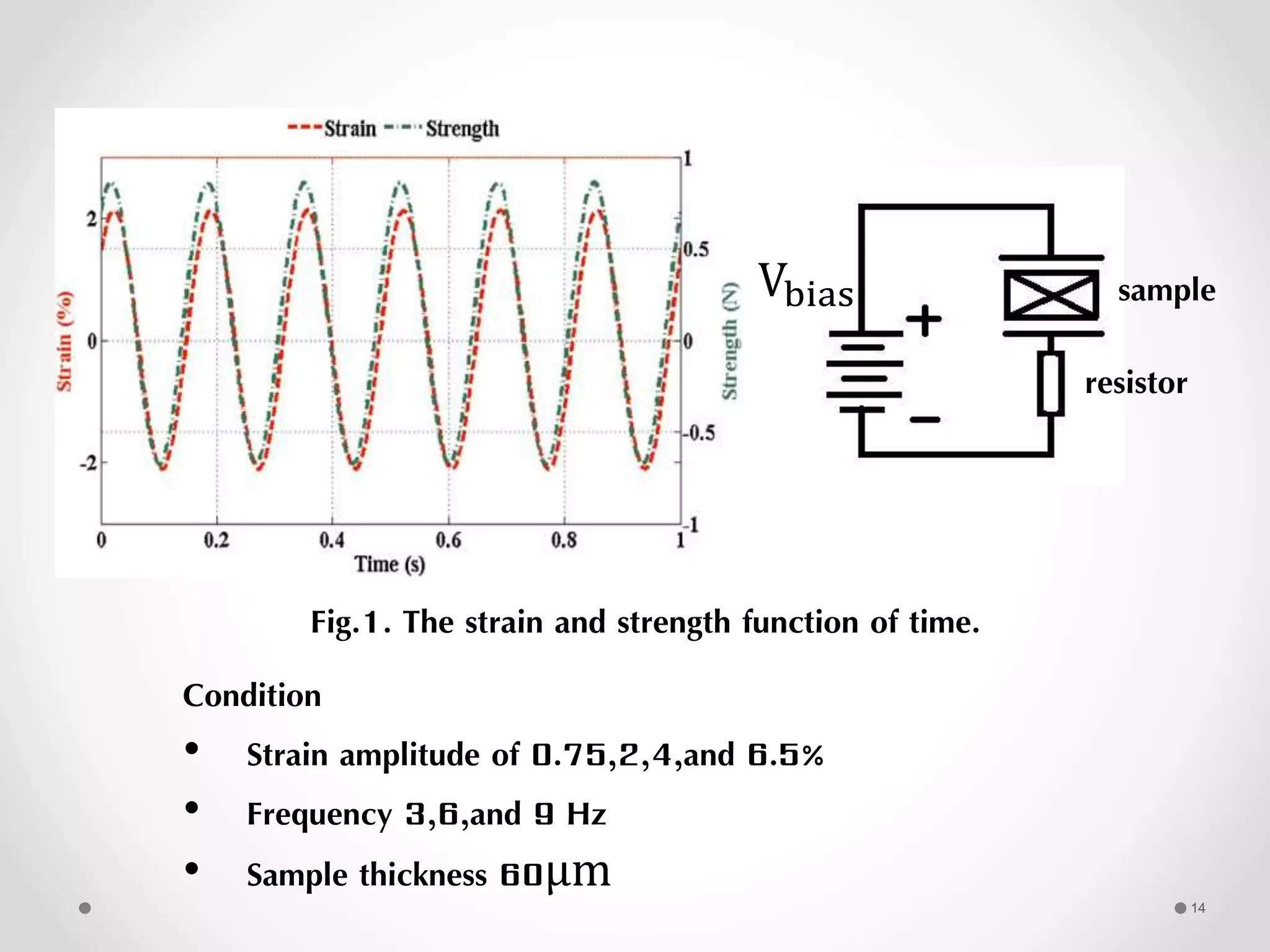

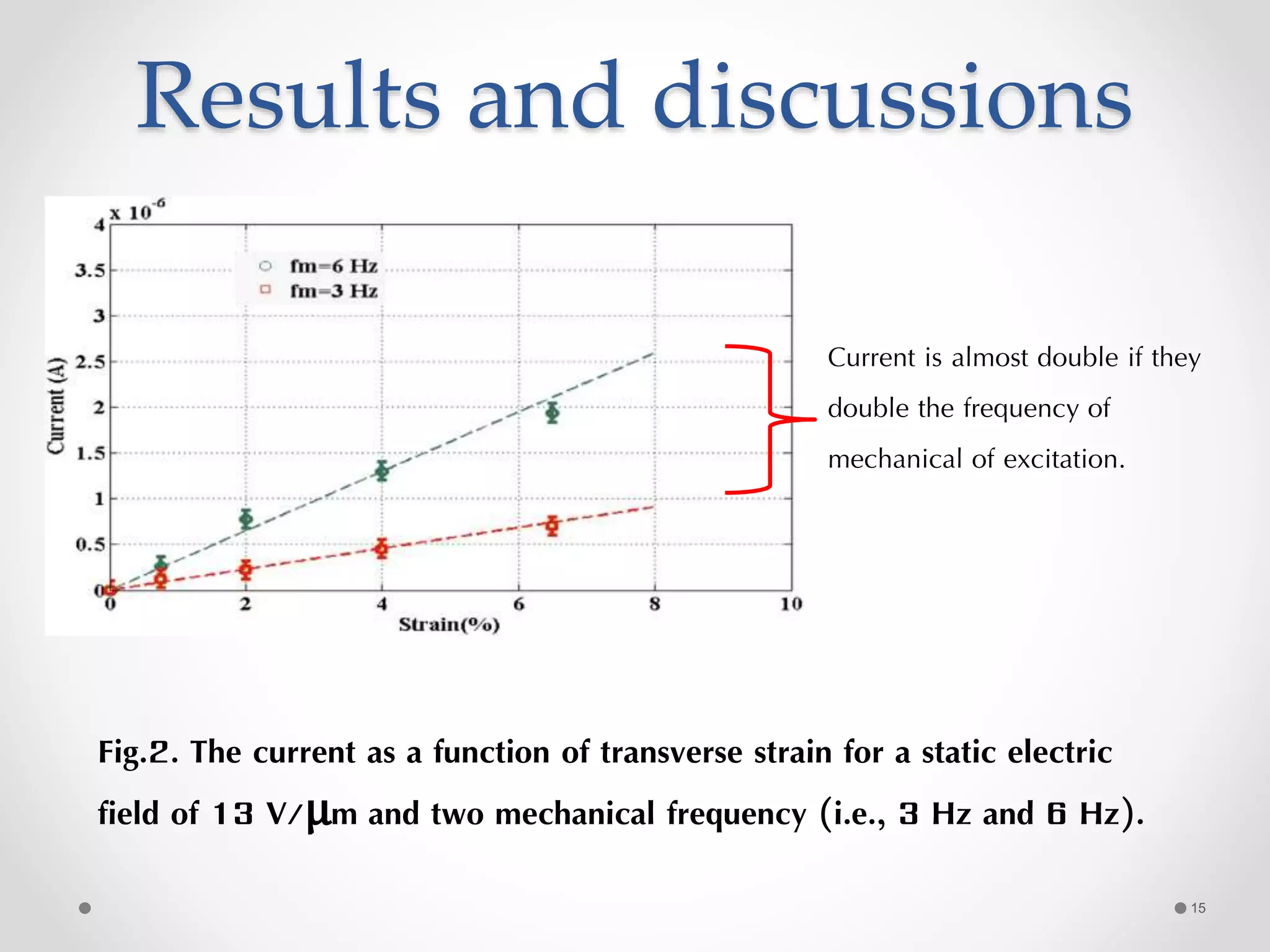

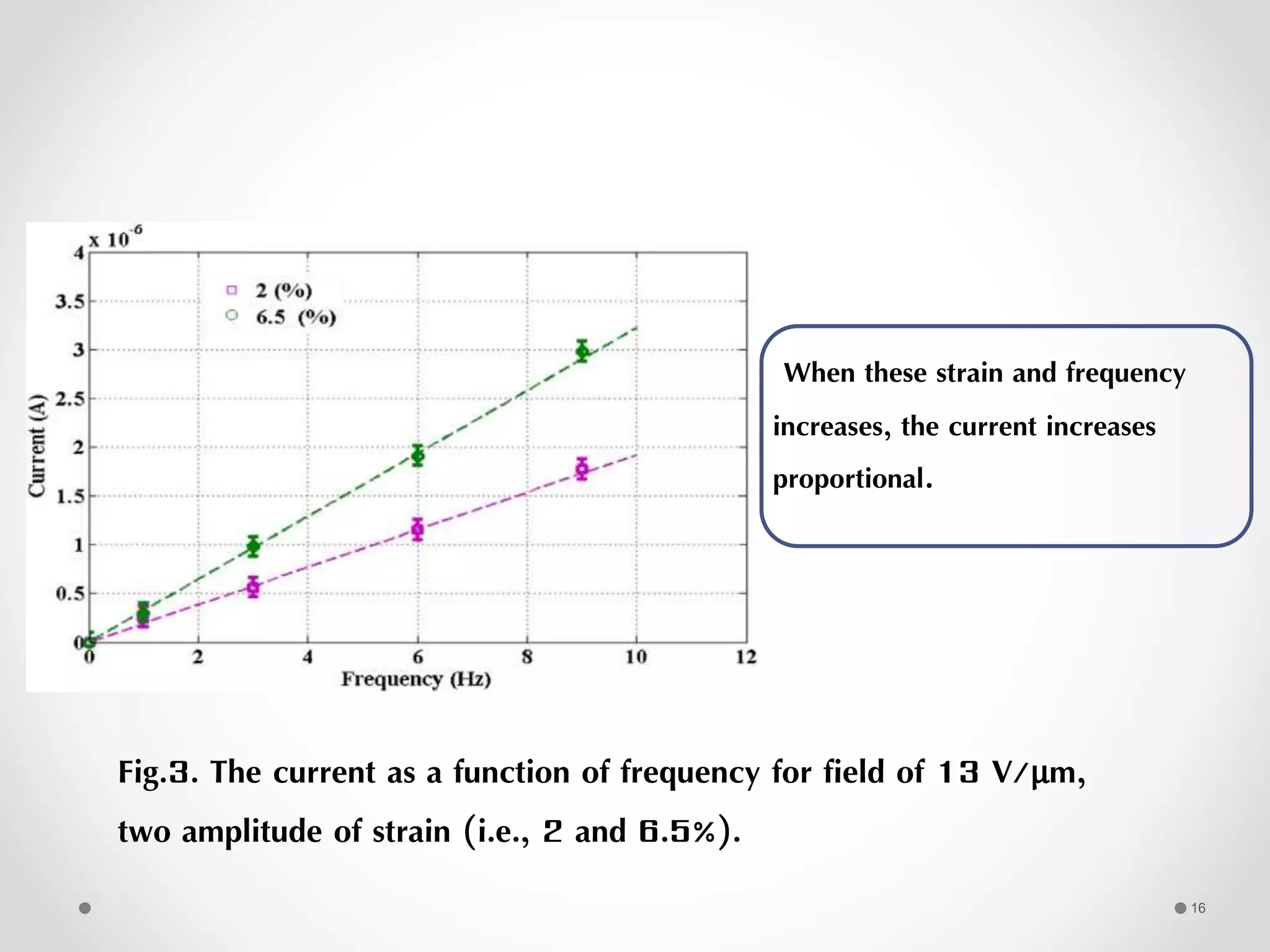

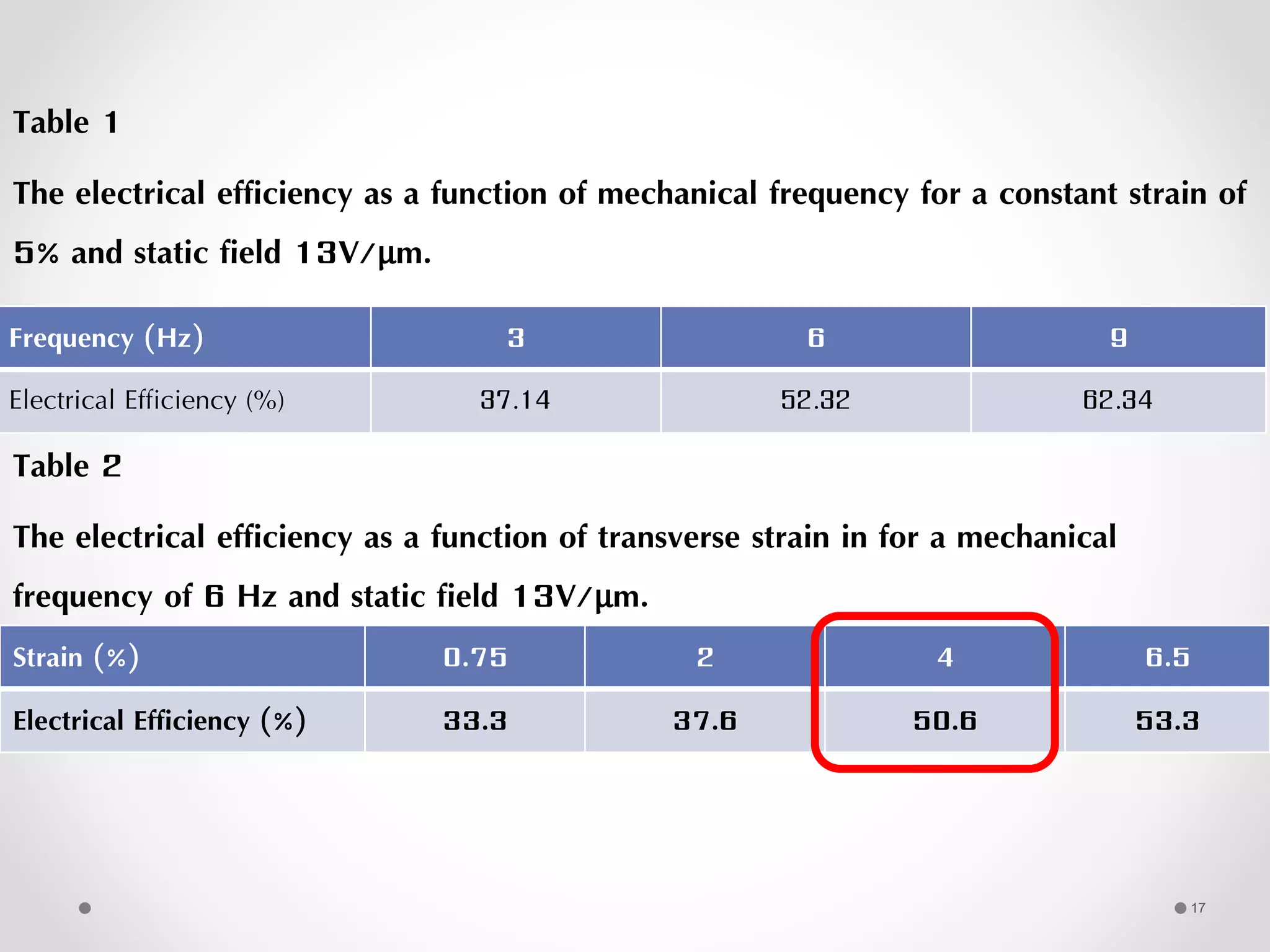

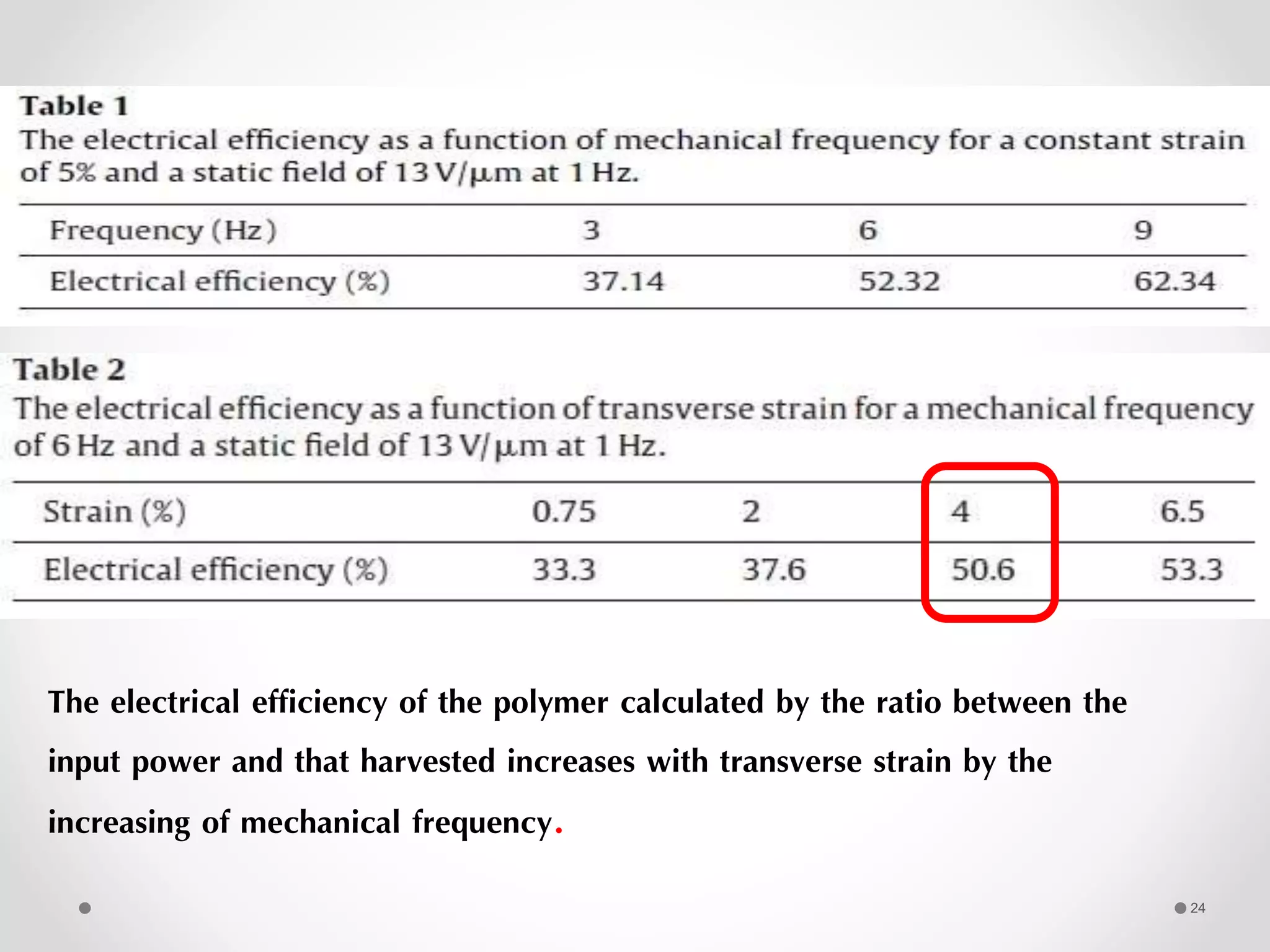

2) An experiment investigating the effect of strain amplitude and operating frequency on the harvested current of an electrostrictive polymer composite film. Results show current increased with higher frequency and strain.

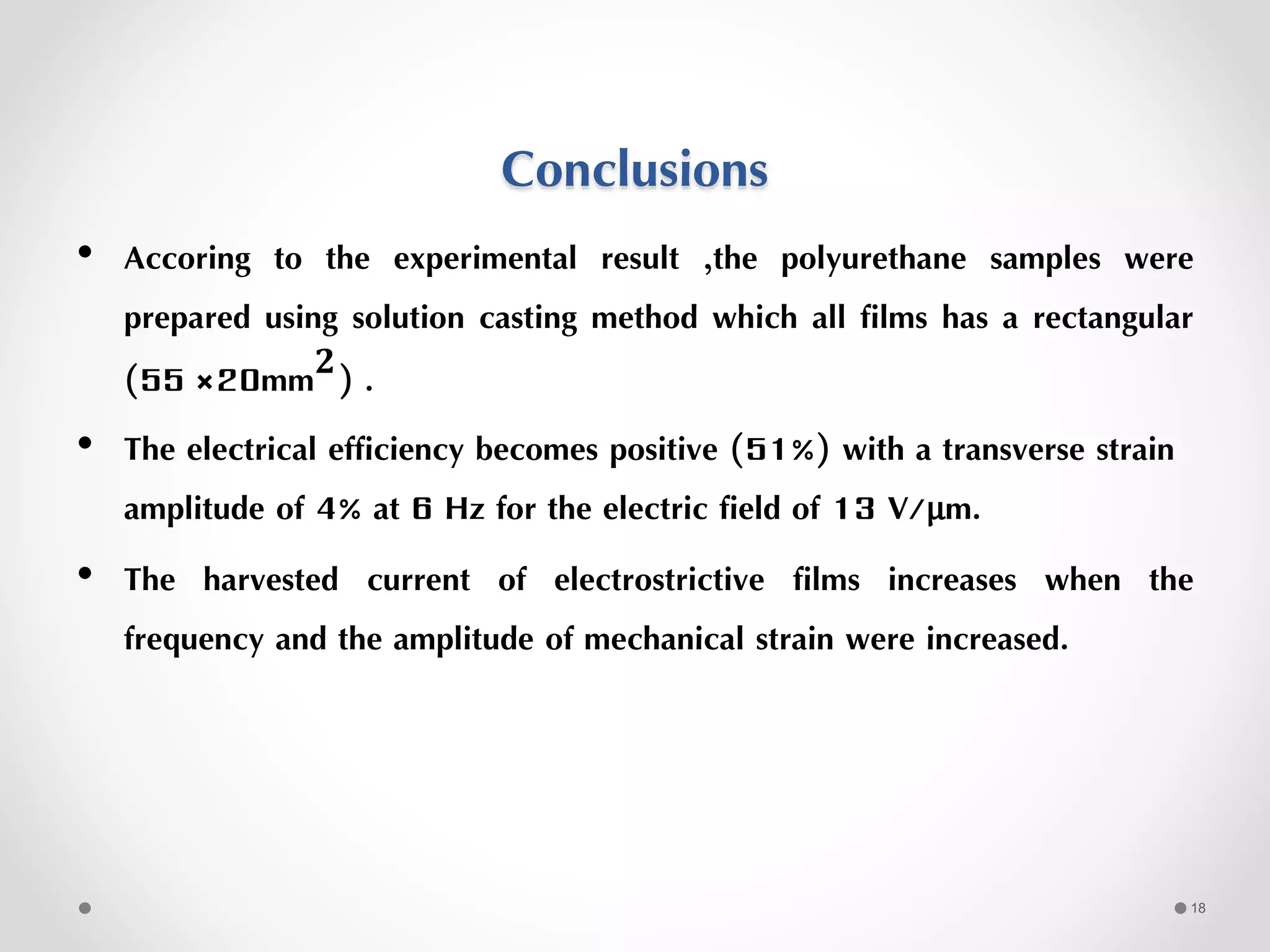

3) A conclusion that the electrical efficiency increases with strain and reaches a maximum of 51% at a strain of 4% and frequency of 6Hz for an electric field of 13V/μm. Higher frequency and strain lead to more harvested current.