This will guide us through the different preparation processes in a simple way

Statistics:

This will let us consult the operations history and the parameters used in each one

Maintenance:

This will show the maintenance status of the unit and its components

Help:

This will show help screens for the different functions

About:

Information about the unit and its software

The software is very intuitive and easy to use, allowing the preparation of samples in a simple,

automatic and reproducible way.

�36

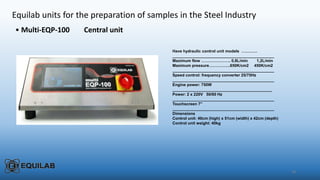

Equilab units for the preparation of samples in the Steel Industry

• MultiEQP-100 Advantages

- Automatic selection of the tool

- Intuitive software

- Reproducible parameters